Ammonia nitrogen wastewater mainly comes from industries such as fertilizers, coking, petrochemicals, pharmaceuticals, and food. Generally, biochemical treatment is used to reduce the ammonia nitrogen content in wastewater. With the rapid development and growth of industries such as fertilizers and petrochemicals, more and more high ammonia nitrogen wastewater is not treated to meet the standard, which has become an important factor restricting the development of the industry.

Ammonia nitrogen wastewater contains a large amount of ammonia ions and free ammonia. If it is not treated and discharged directly into the water body, it will directly cause eutrophication of the water body and disrupt the growth environment of the entire organism.

Moreover, the toxicity of ammonia nitrogen far exceeds that of ammonium salts, and excessive levels can cause toxicity to aquatic organisms.

Especially under conditions of sufficient oxygen, ammonia nitrogen can also be oxidized into nitrite nitrogen by microorganisms, and then combined with proteins to produce nitrosamines. If it enters the human body through aquatic organisms, it will pose a threat of carcinogenesis and teratogenicity.

Current situation of ammonia nitrogen wastewater treatment

To eliminate the threat of ammonia nitrogen containing wastewater to the environment, aquatic organisms, and human health, reliable measures must be taken in a timely manner for treatment. Common methods include blow off, membrane technology, adsorption, chemical precipitation, and biological methods to control the ammonia nitrogen content within the allowable range and minimize its impact on the outside world.

Blow off method: Blow off method is commonly used in the treatment of wastewater containing ammonia nitrogen, which involves introducing gas into the wastewater to promote sufficient contact between dissolved gases and volatile solutes in the wastewater. By adjusting the pH value, the ionized ammonia in the wastewater is converted into molecular ammonia, and finally blown out by the introduced air or steam to reduce the ammonia nitrogen content in the wastewater.

Chemical precipitation method: The chemical precipitation method is applied to remove ammonia nitrogen from wastewater, which involves adding an appropriate amount of Mg2+and PO43- agents to the wastewater containing ammonia nitrogen to promote its reaction with NH4+in the wastewater to form insoluble complex salt magnesium ammonium phosphate MgNH4PO4 · 6H2O crystal precipitation. Finally, the remaining nitrogen and phosphorus in the wastewater are recovered and treated.

Ion exchange method: The most common way to treat wastewater containing ammonia nitrogen using ion exchange method is to use zeolite as an exchange carrier to improve the removal rate of ammonia nitrogen.

Membrane absorption method: 1) The principle of reverse osmosis treatment of ammonia nitrogen wastewater is to use pressure exceeding the osmotic pressure of the solution to selectively intercept solutes through a semi permeable membrane, and reliably separate solutes and solvents. In practical applications, it has the characteristics of low energy consumption, no pollution, advanced technology, and simple maintenance; 2) Electrodialysis technology. By setting an external direct current electric field and selecting the permeability characteristics of the ion exchange membrane, the electrolyte solution is encouraged to separate ions.

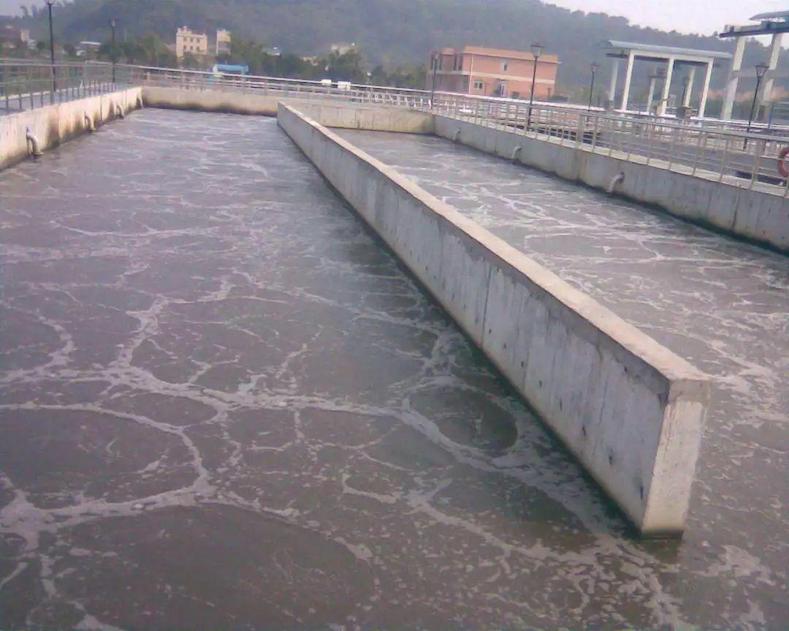

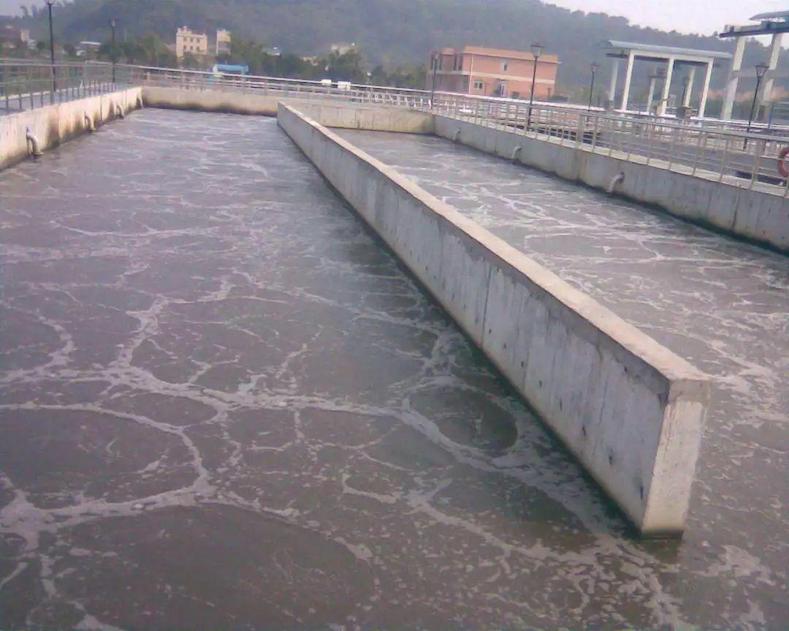

Biological treatment method: nitrification denitrification technology. Traditional biological nitrification denitrification denitrification technology can be applied to the treatment of wastewater containing ammonia nitrogen, which is divided into two stages: nitrification and denitrification.

However, each of these methods has its own advantages and disadvantages, such as high energy consumption, secondary pollution, and still high ammonia nitrogen in the effluent.

For example, traditional biochemical methods have problems such as long processes, large reactors, and large land occupation.

HP808- Ammonia Nitrogen Removal Adsorbent

To meet the needs of enterprises for high removal rate of ammonia nitrogen wastewater, low design investment, low operating costs, advanced technology, and no secondary pollution, etc.

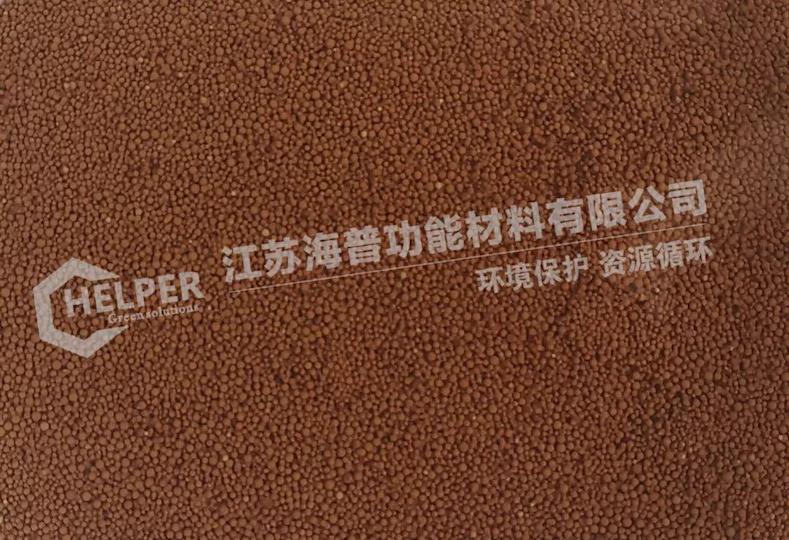

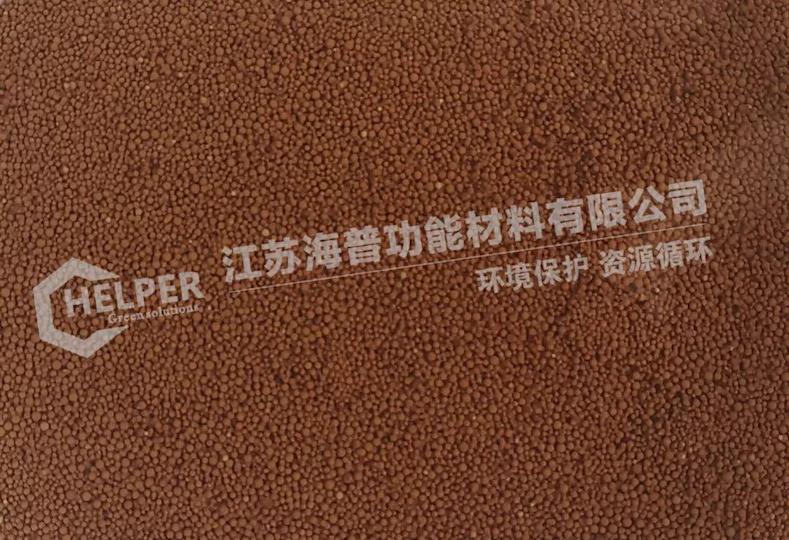

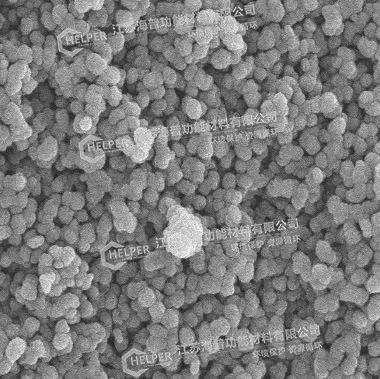

The research team of Haipu Functional Materials has developed an adsorbent product based on the characteristics of typical industry wastewater quality and treatment processes - HP808 ammonia nitrogen removal adsorbent.

HP808 ammonia nitrogen removal adsorbent

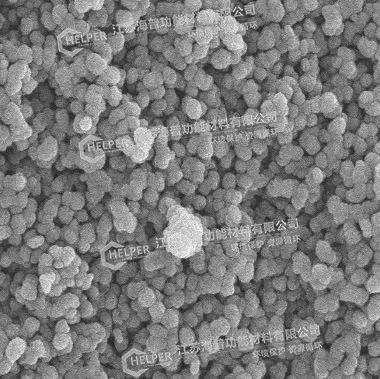

Rich nanopores

Used for the treatment of wastewater containing inorganic ammonia

What are the differences between our ammonia nitrogen adsorbent

Compared with other technologies, Haipu ammonia nitrogen removal adsorbent has significant application advantages in operating costs, operating efficiency, and other aspects.

Haipu ammonia nitrogen adsorbent is suitable for ammonia nitrogen wastewater and can selectively desorb ammonia nitrogen substances in wastewater. It can achieve efficient adsorption and thorough desorption of ammonia nitrogen substances, and the ammonia nitrogen content in the desorbed wastewater can meet the discharge standards.

After adsorption saturation, desorption treatment is carried out using a desorption agent, and the desorbed adsorbent can be regenerated and reused for adsorption.

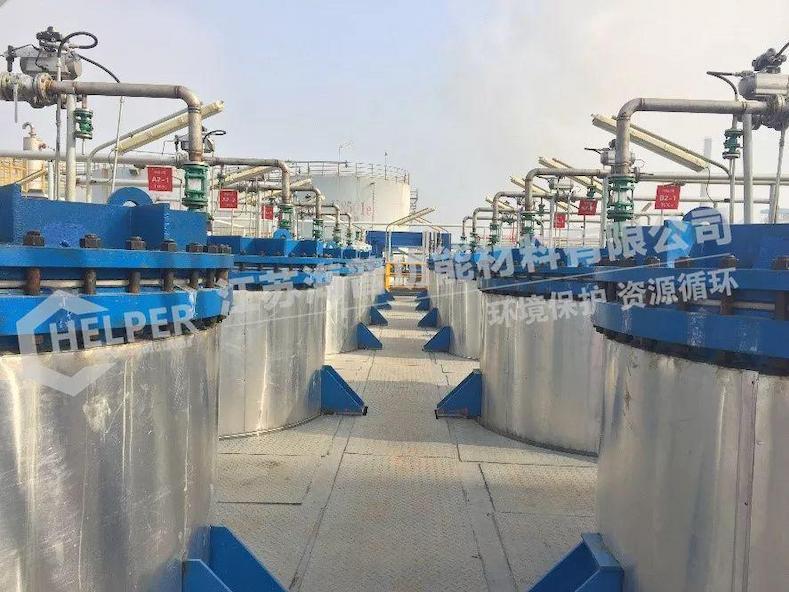

Moreover, it adopts a modular component form, with a high degree of automation and simple operation.

Product application effect

Based on practical and feasible ammonia nitrogen adsorbent products and their supporting combination processes, Haipu has helped multiple customers meet the treatment needs of ammonia nitrogen wastewater.

Application case 1 of ammonia nitrogen adsorbent

A biochemical enterprise needs to treat 300t/d of ammonia nitrogen containing wastewater to solve the problem of high ammonia nitrogen content in the enterprise's wastewater and substandard biochemical treatment.

Using Haipu ammonia nitrogen adsorbent, after process design, the wastewater is first adsorbed to remove most of the ammonia nitrogen substances, and then enters the biochemical system for treatment. The effluent can meet the discharge standards.

| Ammonia nitrogen content in raw water | Ammonia nitrogen content in effluent | Removal rate |

| 300mg/L | 25mg/L | 92% |

| 300mg/L | 24mg/L | 92% |

| 300mg/L | 25mg/L | 92% |

Application case of ammonia nitrogen adsorbent 2

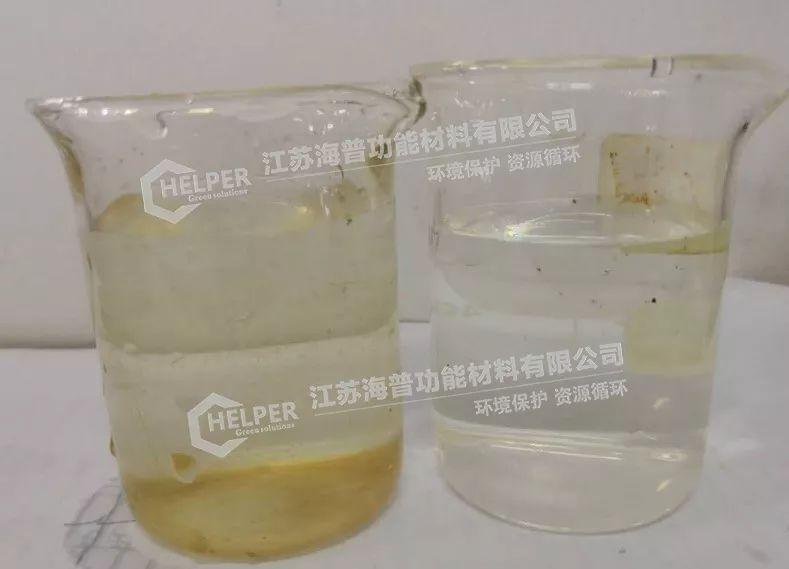

A company requires that the ammonia nitrogen content in the treated wastewater be less than 20 mg/L. Experimental treatment results show that using Haipu ammonia nitrogen removal adsorbent for adsorption treatment can stabilize the ammonia nitrogen removal rate in the wastewater at over 90%, and the ammonia nitrogen content in the effluent can be controlled below 10 mg/L.

Keeping a certain safety margin while ensuring compliance with customer requirements can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent.

| Ammonia nitrogen content in raw water | Ammonia nitrogen content in effluent | Removal rate |

| 112.1mg/L | 7.2mg/L | 93.58% |

| 112.1mg/L | 7.8mg/L | 93.76% |

| 112.1mg/L | 7.8mg/L | 93.76% |

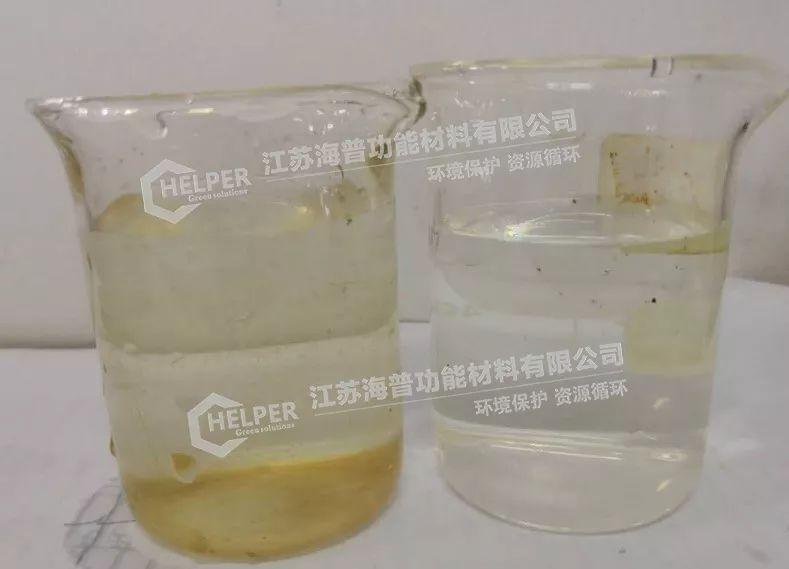

Comparison of Adsorbed Inlet Water and Adsorbed Outlet Water

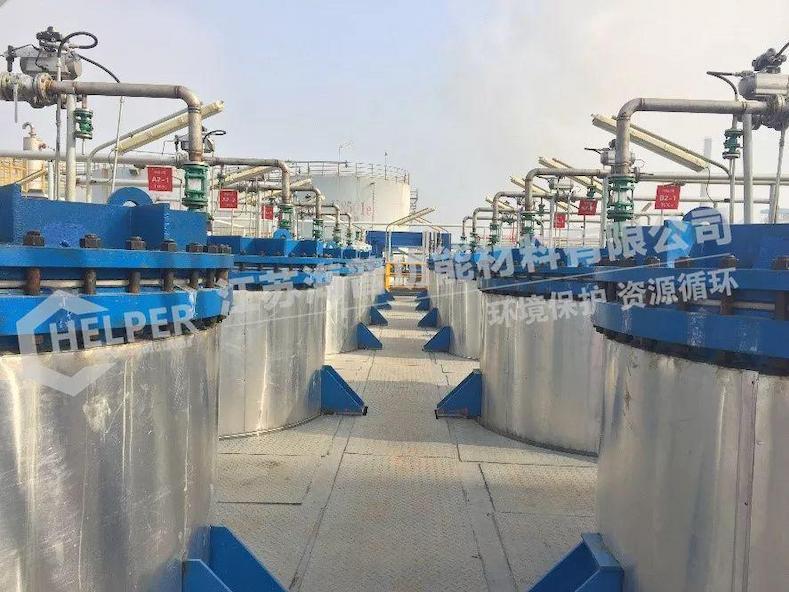

Practical case demonstration of ammonia nitrogen adsorbent application

CN

CN