1. Current situation of exhaust gas treatment

In recent years, China's economy has steadily developed, industrialization has accelerated, and a large amount of industrial waste gas has been generated. The proportion of volatile organic compounds (VOCs) in China's environmental pollution is increasing, gradually becoming one of the main pollutants in the environment. As the chemical industry faces environmental pressures and the requirements for volatile organic compound remediation continue to increase, waste gas treatment technology has become an inevitable choice for chemical enterprises.

At present, common VOCs end treatment processes include direct combustion, catalytic combustion, adsorption, absorption, low-temperature plasma technology, biological filtration technology, etc. The adsorption method and combustion method are relatively mature and have engineering technical specifications. However, there are shortcomings in certain methods, such as combustion, carbon adsorption, and low-temperature plasma technology, which have insufficient safety and often lead to process explosion accidents. Absorption methods are difficult to treat VOCs with stable chemical properties, while biological methods are suitable for organic waste gases with relatively simple components and have low treatment effects on waste gases with complex components.

2. Adsorption principle

VOCs adsorption is the process of using adsorbents to adsorb a certain solvent in a gas, allowing it to accumulate in the pores of the adsorbent, thereby achieving the recovery of volatile solvents and meeting the standards for waste gas treatment (or reducing the burden for subsequent compliance); Desorption is the reverse process of adsorption, in which the adsorbed solvent is released from the adsorbent under certain conditions, allowing the adsorbent to be regenerated (reused for adsorption).

The VOCs adsorption and regeneration process is relatively simple, and the core technology of this process is the adsorbent material itself. Jiangsu Haipu Functional Materials focuses on the research and industrial application of special adsorption functional materials. Based on the physical and chemical characteristics of different VOCs, adsorbents with different pore structures and surface properties are used to achieve efficient adsorption recovery and standard treatment of VOCs, ensuring the reliability and stability of the engineering application of adsorption materials.

3. Introduction to Haipu Customized Process

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

The new polymer nano adsorbent developed by our company has the following advantages compared to traditional adsorbents such as activated carbon (fiber) widely used in the market:

(1) The effective specific surface area of the material is over 1000m2/g, and the adsorption capacity is high;

(2) The pore structure of the material is uniform and can be adjusted according to the characteristics of the processed gas (the pore structure of the carbonaceous adsorbent is uneven, and the micropores are prone to blockage and deactivation);

(3) The functional groups of the material are diverse and can be selected based on the characteristics of the gas being processed;

(4) The material has good physical and chemical stability, is resistant to acid, alkali, and organic solvents, has high thermal stability and mechanical strength, and is wear-resistant (carbon adsorbents have a brittle structure and are prone to wear, breakage, or pore collapse during use);

(5) The surface of the material exhibits high hydrophobicity, and humidity has no effect on the adsorption performance of VOCs (carbon adsorbents have a high ash content and a hydrophilic surface, and humidity has a significant impact on their adsorption performance);

(6) The material is easy to regenerate and has stable adsorption performance (the regeneration of carbonaceous adsorbents is not thorough, and the adsorption performance deteriorates rapidly after multiple regenerations);

(7) The surface of the material has no catalytic effect and can be used to adsorb easily decomposed organic gases such as chlorinated hydrocarbons (adsorbent materials such as carbon have a certain catalytic effect due to the presence of metal and other impurities on the surface, and after adsorbing chlorinated hydrocarbons, chemical reactions occur to generate HCL, which corrodes equipment and valves).

(8) The material has high chemical inertness and can be used to adsorb chemically active substances such as ketones, ethers, and esters (carbon materials undergo chemical reactions during adsorption, causing bed fires and posing safety hazards).

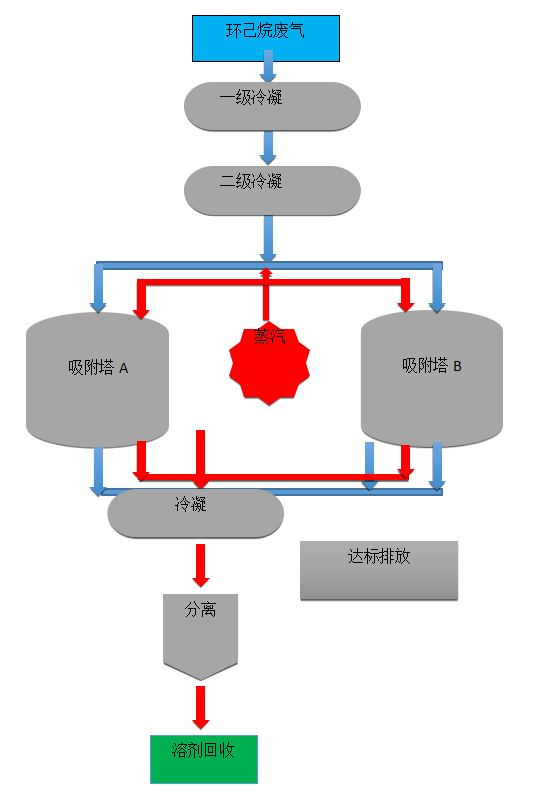

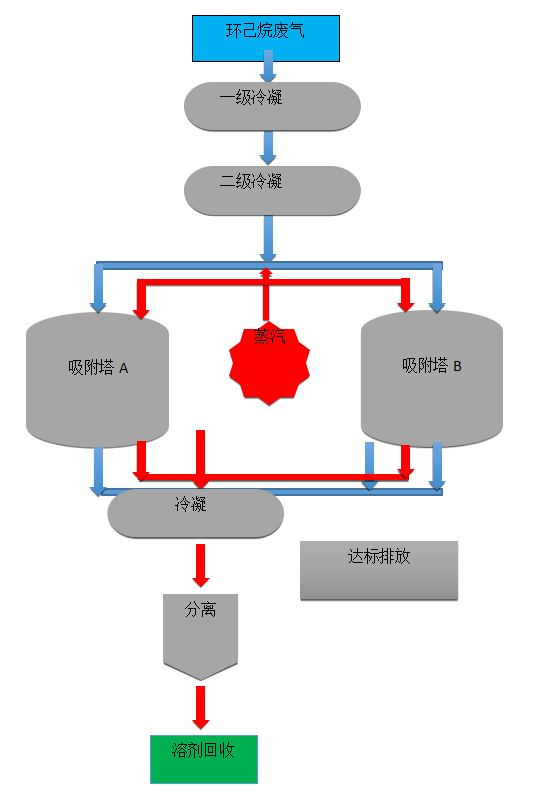

4. Process diagram for adsorption treatment of cyclohexane waste gas

In response to the current problems in the treatment of cyclohexane waste gas, Jiangsu Haipu Functional Materials Co., Ltd. has developed HDV type polymer nanoadsorbent, which can adsorb and remove cyclohexane from waste gas. After adsorption saturation, the nano adsorbent is desorbed and regenerated using steam, and cyclohexane vapor can be condensed and recovered. The specific process is as follows:

5. Case Introduction: Cyclohexane Waste Gas Treatment Project of a Petrochemical Enterprise in Hunan Province

The company uses our adsorption process to treat the cyclohexane waste gas generated during its production process, with a waste gas flow rate of 600Nm³/h and a waste gas concentration of~60000mg/m³. By adopting our company's waste gas treatment process, the concentration of cyclohexane waste gas can be reduced to 100 mg/m³, and the treated waste gas meets the emission standards. At the same time, cyclohexane solvent can be recovered, bringing additional economic benefits to the enterprise.

CN

CN