The textile dyeing industry is a major consumer of industrial water and a significant source of wastewater discharge in China. According to incomplete statistics, the discharge volume of dyeing wastewater in China is approximately 3×10^6 to 4×10^6 m³/day, accounting for about 35% of the total industrial wastewater discharge. However, the reuse rate of treated dyeing wastewater is less than 10%.

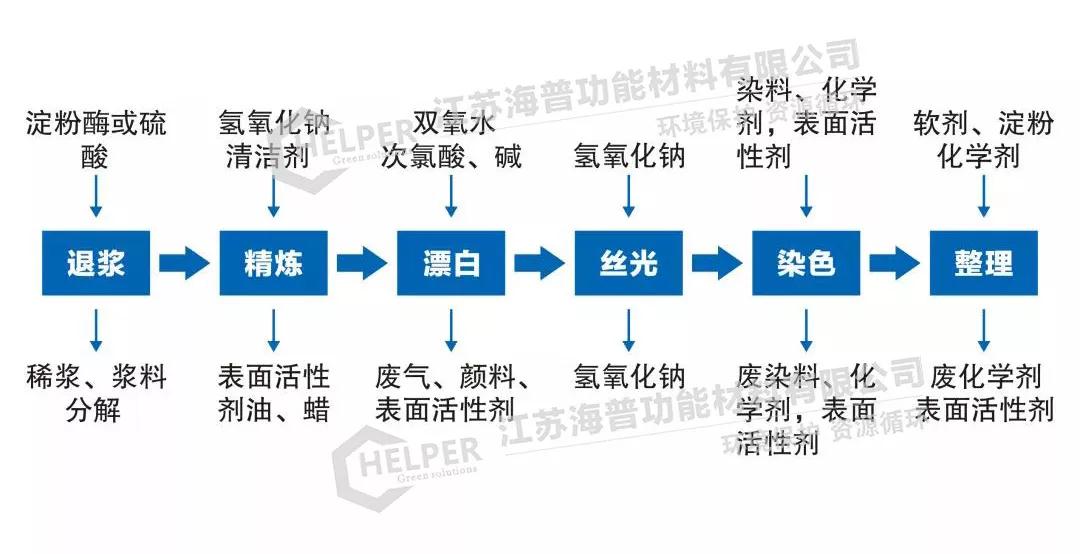

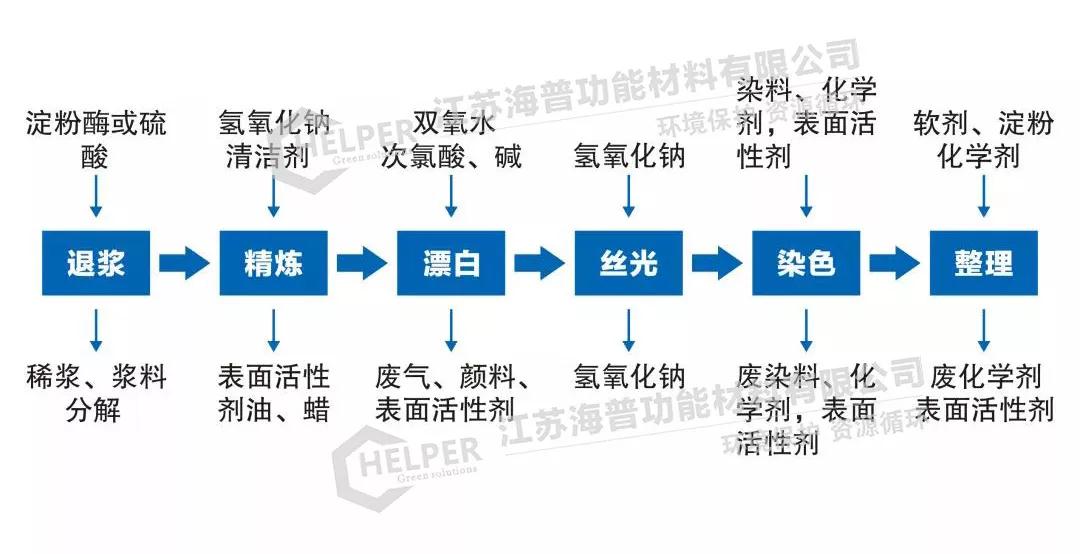

Dyeing wastewater treatment mainly refers to the wastewater discharged from various stages of the dyeing process, including desizing wastewater, mercerizing wastewater, dyeing wastewater, printing wastewater, and finishing wastewater.

China is a country with scarce water resources, with per capita water resources only one-fourth of the world average, and these resources are unevenly distributed and poorly utilized.

Deep treatment of dyeing wastewater to increase its reuse rate is of significant practical and economic importance for alleviating the water resource crisis and maintaining the sustainable development of the dyeing industry.

Current Status of Dyeing Wastewater Treatment

With the increasing volume of wastewater discharge, it poses a serious threat to ecological safety and human health. For a long time, dyeing wastewater, due to its high concentration of organic matter, high salinity, and difficulty in biodegradation, has been a challenging issue in industrial wastewater treatment.

Additionally, the variety of dyes, their complex compositions, and their development towards photostability, oxidation resistance, and biodegradation resistance have severely challenged traditional dye wastewater treatment processes, making it difficult to meet discharge requirements.

Therefore, developing economical and efficient methods or technologies for dyeing wastewater treatment has increasingly become a focus in the wastewater treatment industry.

Currently, the main methods for treating dyeing wastewater include biological methods, extraction methods, adsorption methods, incineration methods, chemical oxidation methods, advanced oxidation methods (wet oxidation, photocatalytic oxidation, supercritical water oxidation, Fenton oxidation, electrochemical oxidation), and various combined methods.

Biological Method: Utilizes the metabolism of microorganisms to achieve the treatment of organic pollutants in wastewater through coagulation, adsorption, and oxidative decomposition. Its advantages include a wide application range, large treatment capacity, and low treatment cost. However, it also has drawbacks such as long treatment cycles, low resource utilization of sludge, and the potential toxicity or difficulty in biodegradation of some organic pollutants in the wastewater.

Extraction Method: Uses non-water solvents that are immiscible with water but have strong solubility for organic pollutants. By fully mixing with the wastewater, the pollutants are transferred to the non-water solvent, and then the water and solvent are separated to remove organic pollutants from the water. Currently, the extraction method is only suitable for treating a few types of organic wastewater.

Chemical Oxidation Method: Uses strong oxidants to degrade organic pollutants in water through oxidation. Its advantages include simple processes and equipment, but it has high treatment costs, general effectiveness on organic matter, and can cause secondary pollution.

Advanced Oxidation Method: Involves generating hydroxyl radicals and other radicals during water treatment to oxidize large, hard-to-degrade toxic organic molecules into low-toxicity or non-toxic small molecules, or even directly mineralize them into CO2 and H2O. This is a new water treatment method.

Fenton Oxidation Method: An advanced oxidation method using hydrogen peroxide as the oxidant and ferrous salts as the catalyst. Under slightly acidic conditions, strong oxidative radicals generated in the reaction can quickly oxidize pollutants in the wastewater.

Adsorption Method: Uses the porous physical structure and large specific surface area of adsorbents to achieve the adsorption and purification of dyeing wastewater. The adsorption method has advantages such as low equipment investment, good treatment effect, and small footprint.

Series of Adsorbents for Dyeing Wastewater Treatment

HP355/HP266/HP388/HP516

To address the issue where the COD of wastewater discharged by dyeing enterprises remains far above discharge requirements and has high color intensity even after biochemical and various filtration treatments,

Haipu Functional Materials' research team has developed a series of adsorbent products based on the characteristics of wastewater quality and treatment processes in typical industries—HP355/HP266/HP388/HP516.

Series of Adsorbents for Dyeing Wastewater Treatment

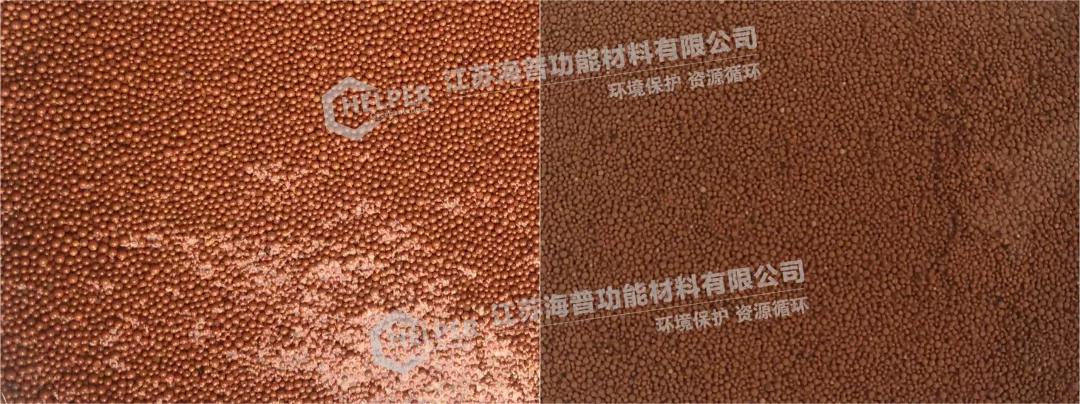

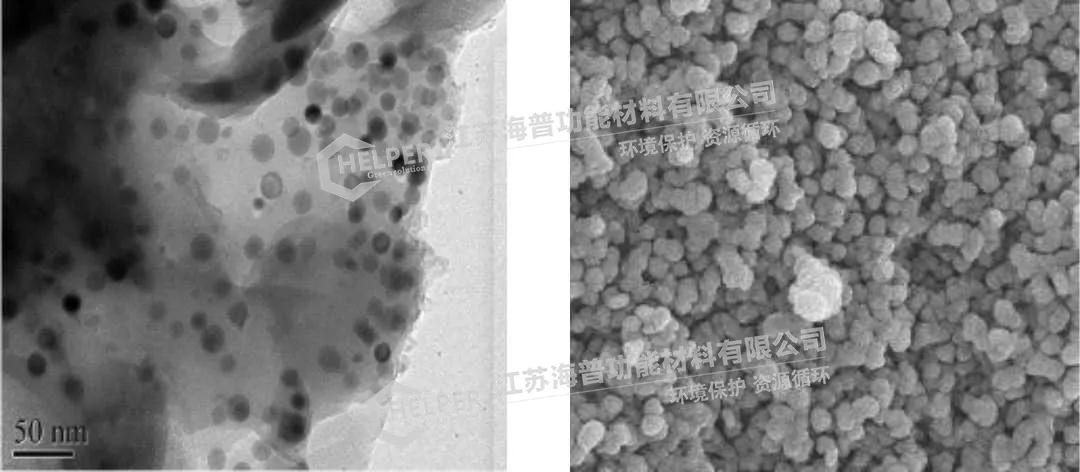

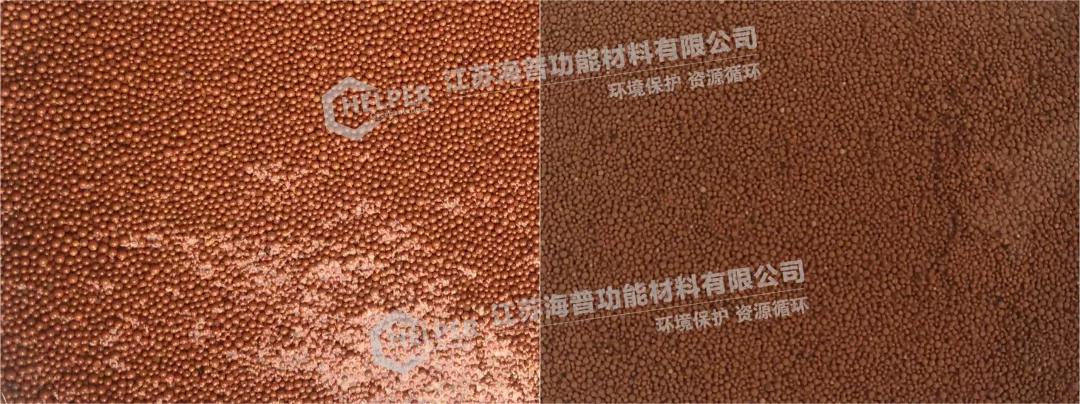

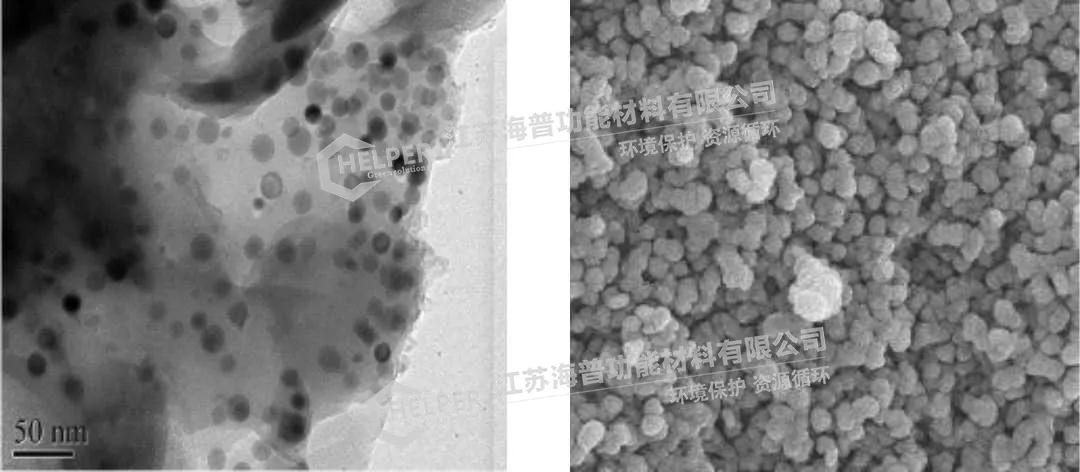

Microscopic View of Active Nanoparticles and Rich Internal Nanopores

HP355/HP266/HP388/HP516

Used for treating high-COD, high-color dyeing wastewater and for reclaimed water reuse.

What Makes Our Special Adsorbents Different

Compared to other treatment technologies, Haipu’s special adsorbent materials have a large adsorption capacity, are regenerable, and have a long service life.

They can reduce the COD content and color intensity of wastewater, meeting the reclaimed water reuse requirements of enterprises (COD content <50 mg/L).

They lower the wastewater treatment costs for enterprises, cause no secondary pollution, and the entire treatment equipment is modular, highly automated, and easy to operate.

After adsorption saturation, the adsorbent is regenerated using a desorbent, allowing it to be reused for adsorption.

Product Application Effectiveness

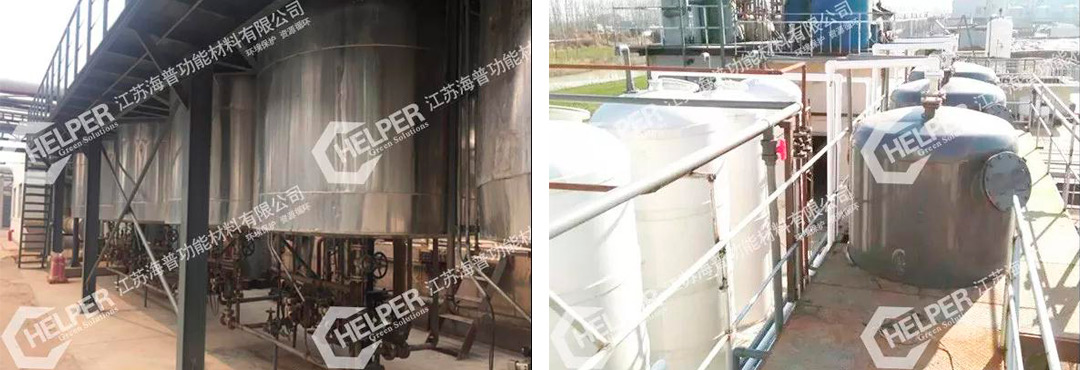

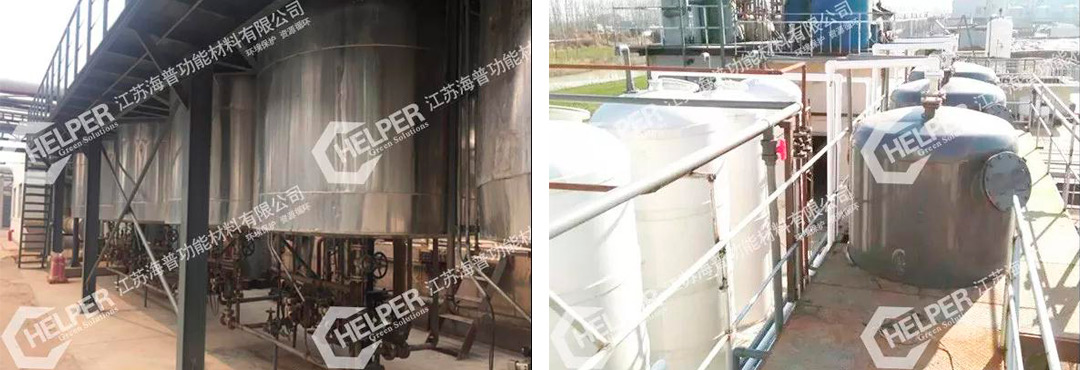

Relying on practical special adsorbent products and their supporting combination processes, Haipu has successfully met the treatment needs of multiple textile, dyeing, and pigment customers.

Application Case 1

A dyeing enterprise’s production process generates wastewater that, even after biochemical and various filtration treatments, still has a COD far above discharge requirements and high color intensity, requiring further treatment.

Using Haipu’s special adsorbent materials for experimental treatment of the wastewater showed that it could specifically separate hard-to-degrade organic matter from the wastewater, and the adsorption effluent met discharge standards.

| Raw Water COD Content | Effluent COD | Appearance of Raw Water | Appearance of Effluent |

| 260mg/L | 46.4mg/L | Brown | Colorless and Transparent |

| 260mg/L | 48.0mg/L | Brown | Colorless and Transparent |

| 260mg/L | 47.2mg/L | Brown | Colorless and Transparent |

Comparison Before and After Treatment

Application Case 2

A textile enterprise's production process generates approximately 2500 tons of wastewater daily. Policy mandates that the reuse rate of dyeing industry wastewater must reach 60%. The enterprise's current wastewater treatment process results in biochemical tailwater with COD exceeding standards, failing to meet reuse standards.

Based on the enterprise's production needs, using Haipu's special adsorbent materials in combination with the adsorption process to treat the wastewater can meet reuse requirements. This not only solves the enterprise's wastewater treatment challenges but also reduces the costs of outsourcing wastewater treatment and adding new water, providing significant economic value.

| Raw Water COD Content | Effluent COD | Appearance of Raw Water | Appearance of Effluent |

| 164mg/L | 40.5mg/L | Brown | Colorless and Transparent |

| 164mg/L | 42.3mg/L | Brown | Colorless and Transparent |

| 164mg/L | 41.4mg/L | Brown | Colorless and Transparent |

Practical Application Cases of Adsorbents for Dyeing Wastewater Treatment

CN

CN