With the development of human society, water resources have become increasingly scarce, which is an important issue facing humanity. Among them, coking enterprises need to deal with water issues well. On the one hand, in the operation process of coking enterprises, new water needs to be continuously replenished for cooling circulation and boiler water replenishment. On the other hand, it is also necessary to treat high concentration coking wastewater, which can be used to treat polluted water, thereby protecting the environment and achieving sustainable development. Therefore, adopting advanced sewage treatment technology can address the above issues, thereby achieving water resource conservation and improving water utilization efficiency.

1. The current situation and problems of advanced treatment of coking wastewater

1.1 Insufficient emphasis on advanced treatment of coking wastewater

Some coal coking processing enterprises have not yet established a sound management system and scientific production technology. In order to pursue profits, some enterprises have not yet reached the standards stipulated by regulations in the advanced treatment of coking wastewater, and have not invested enough in advanced treatment equipment, resulting in incomplete treatment. Due to inadequate regulation, some coking coal processing enterprises only conduct extensive treatment of coking wastewater before discharging it. Greatly wasting resources and causing significant pollution to the environment.

1.2 Traditional coking wastewater deep treatment processes are not yet perfect

The deep treatment of coking wastewater mainly relies on chemical treatment, but a single chemical treatment method cannot achieve effective treatment results. The commonly used deep processing methods in practice include physical processing and chemical processing. In order to achieve the required wastewater treatment quality according to regulations, several treatment methods are generally used in combination. Due to the fact that the deep treatment of coking wastewater in China has just begun, commonly used treatment processes include wet quenching, blast furnace slag flushing, coal yard dust suppression, converter gas washing water, dust removal water, sintering mixing, and industrial water supply. These processes still have certain defects and are prone to secondary pollution transfer, resulting in serious waste of water resources. The main reason is that domestic enterprises tend to choose a combination of chemical treatment and membrane separation processes for advanced coking treatment. On the one hand, due to the high susceptibility of the treatment membrane in the membrane separation process to contamination, frequent membrane cleaning, and limited membrane service life, the effluent water quality treated by this process cannot fully meet the standards. On the other hand, the repeated use of treatment membranes has caused secondary pollution problems. Due to the impact of equipment investment costs, frequent replacement of treatment membranes is too expensive, and many companies are unwilling to invest in equipment maintenance funds in this area.

1.3 Traditional coking wastewater deep treatment processes have high costs

From current practice, various processes for advanced treatment of coking wastewater in China have the problem of high costs. The high processing cost is partly due to the lack of scientific and reasonable combination of various processes for deep processing. On the other hand, many enterprises are still stuck in the treatment process of wastewater, without the idea of turning waste into treasure through waste recycling and reuse. The organic matter rich in coking wastewater can be well recovered, which can also increase the income of enterprises and reduce the cost of wastewater treatment. The effective control of treatment costs in coking wastewater treatment processes can better stimulate the enthusiasm of enterprises.

Coking wastewater is a typical complex industrial wastewater with salt polymorphism, nitrogen and phosphorus nutrient imbalance, and high toxicity. The treatment process is long and difficult. At present, the conventional treatment methods mainly include biochemical treatment, physical and chemical treatment, and combined treatment.

2. Biochemical method

2.1 Aerated biological filter

The biological aerated filter (BAr) is mainly used in the advanced treatment of coking wastewater after conventional biochemical treatment (such as A/O, A2/O). A two-stage anaerobic and aerobic upflow biological aerated filter (UBAF) was used for deep treatment of the secondary biochemical effluent from a coking plant. The results showed that under the optimal experimental conditions, the effluent COD and ammonia nitrogen met the second and first level discharge standards of the Comprehensive Wastewater Discharge Standard (GB8987-1996), respectively (unless otherwise specified in the following text). BAF technology has been applied in the deep treatment of coking wastewater in engineering. A certain coking company adopted the MO-BAF treatment process for phenol cyanide wastewater, in which the removal rates of COD and ammonia nitrogen by BAF were 20% and 50% respectively, and the treated effluent met the requirements of the national first-class discharge standard. Adding coagulation air flotation before BAF can effectively remove suspended solids in wastewater, thereby increasing the operating cycle of the biological aerated filter and reducing the number of backwash cycles.

2.2 Membrane bioreactor

Membrane bioreactor (MBR) is also used in the advanced treatment of coking wastewater after conventional biochemical treatment, playing a dual role of biochemical post-treatment and reverse osmosis pretreatment. The 70m3/h coking wastewater treatment project adopts the "MO+MBR" process. When the COD of the biochemical influent is less than 200mg/L, the effluent COD after MBR treatment is ≤ 85mL and BOD5 is ≤ 20mL. After MO process, MBR was used for deep treatment of coking wastewater, and the results showed that MBR treatment is efficient and stable, and the acute toxicity of wastewater is greatly reduced; Membrane fouling is mainly caused by the colloidal components of sludge supernatant. Physical cleaning can remove particles on the membrane surface, but severe membrane fouling caused by long-term operation can only be eliminated by chemical cleaning.

Directly adding MBR or BAF for deep treatment of coking wastewater after traditional biochemical treatment may not achieve ideal treatment results at times. This is because the concentration of biodegradable organic matter in the effluent is very low and the biodegradability is poor after the coking wastewater is subjected to HRT for tens to hundreds of hours of biochemical treatment. Therefore, advanced oxidation processes can be added before BAF or MBR to improve the biodegradability of wastewater.

3. Physical chemistry method

3.1 Coagulation sedimentation method

The coagulation precipitation method is a method of removing pollutants that are difficult to precipitate or filter in wastewater by adding coagulants and flocculants to the wastewater through adsorption, bridging, and net capture, and then removing them through precipitation. This method is mainly used in the deep treatment of coking wastewater to remove organic matter, dissolved inorganic substances such as nitrogen and phosphorus that have not been degraded by microorganisms in the secondary treatment. Common coagulants include polyferric sulfate (PFS), polyaluminum chloride (PAC), and polyacrylamide (PAM).

3.2 Adsorption method

Adsorption method is a method of using the adsorption effect of adsorbents to remove pollutants from wastewater. The adsorption method has good removal effects on ammonia nitrogen, cyanide, and persistent organic compounds with high environmental hazards in coking wastewater. The commonly used adsorbents in the deep treatment of coking wastewater include activated carbon, fly ash (including furnace ash and quenched coke powder), coal powder, steel slag, bentonite, diatomaceous earth, zeolite, and macroporous resin. The application research of activated carbon adsorption in industrial wastewater is relatively in-depth, but it is difficult to recover due to its high price; In recent years, macroporous resins have attracted extensive research due to their high adsorption capacity and easy regeneration.

Jiangsu Haipu Functional Materials Co., Ltd. is a high-tech enterprise dedicated to the research and development of high-performance adsorbents, catalysts, and their process applications. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with independently developed process technology, Haipu has become a professional solution provider in the fields of environmental governance and resource recycling. At the same time, taking it as our responsibility to help industrial enterprises meet environmental standards and achieve sustainable development through resource utilization, we adopt modular lean production and develop engineering solutions based on research and development data.

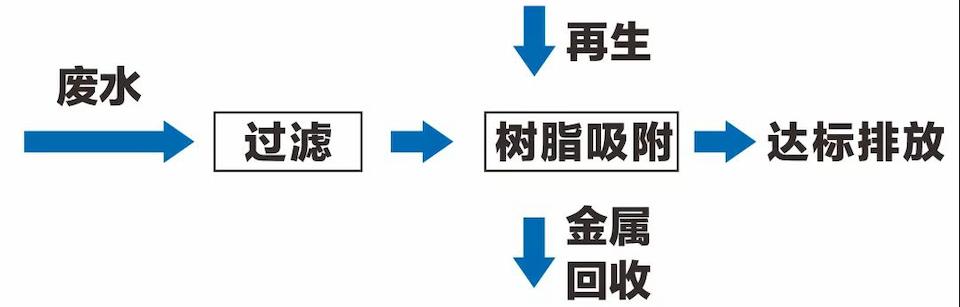

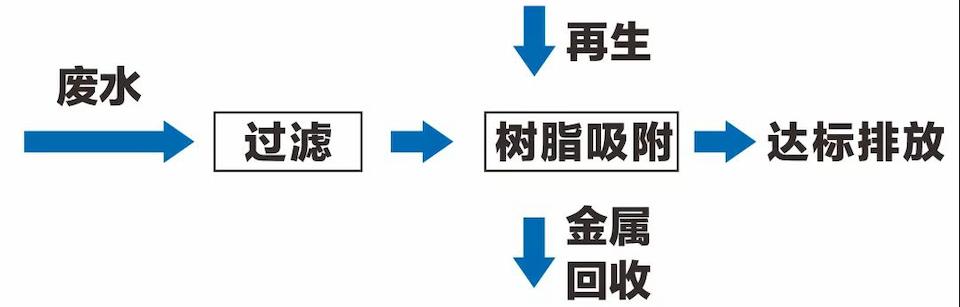

Haipu has developed a series of special adsorption resins based on the properties of organic wastewater, which can selectively adsorb the main components and greatly reduce the COD, chromaticity and other indicators of wastewater. They can be directly discharged in compliance with standards or combined with subsequent biochemical treatment to meet standards. The process flow is as follows:

The business scope of a new energy company includes investment in coal chemical engineering projects, research and development of coal application technologies, production of coal chemical products such as methanol, dimethyl ether, liquefied natural gas, and liquid oxygen, as well as thermal production, supply, and power generation. The biochemical wastewater COD generated during the production process of enterprises is high. Currently, activated carbon adsorption is used to reduce the COD of wastewater. Powdered activated carbon is directly put into the coagulation sedimentation tank or aeration tank during the adsorption process and discharged with sludge, and cannot be recycled. The enterprise consumes around 2500 tons of activated carbon per year. Calculated at a unit price of 6000 yuan/ton, the cost of adding activated carbon per year is as high as 15 million yuan. At the same time, the adsorption of activated carbon generates a large amount of sludge, which poses great difficulties for the subsequent MBR membrane and pressure filtration processes, and is not conducive to the healthy and stable production of enterprises.

The special new high-capacity adsorbent developed by our company has been successfully applied to multiple leading enterprises in the industry. Compared with activated carbon adsorbent, it has the following advantages:

① Has high stability and mechanical strength, is wear-resistant, has a long service life, can be repeatedly regenerated after adsorption saturation, and can maintain a service life of 3-5 for adsorption materials in general wastewater treatment processes;

② Special adsorption materials have an effective specific surface area of over 1200m2/g, with large adsorption capacity and low usage. The supporting equipment occupies a small area, saving project investment costs;

③ The device adopts a modular assembly form, with a short construction period, and the entire system realizes full automation control. The operation and management are simple, effectively reducing the labor cost of the system.

Our company conducted on-site pilot experiments to verify the coal chemical wastewater, and the experimental results met the production requirements of the enterprise. While effectively removing difficult to degrade COD from the wastewater, it can reduce the operating costs and environmental risks of wastewater treatment, reduce equipment usage and maintenance costs, and take into account the dual advantages of production economy and stability.

3.3 Membrane Separation Method

Membrane separation method, as an important advanced wastewater treatment technology, mainly includes microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. There is basically no phase change during the treatment process, which can be operated at room temperature and has the characteristics of high efficiency, low energy consumption, low investment, and simple operation. It has become one of the research hotspots in the deep treatment of coking wastewater. Currently, the application of membrane separation method in the deep treatment of coking wastewater is usually a combination process of ultrafiltration (UF)+reverse osmosis (RO) or ultrafiltration (UF)+nanofiltration (NF).

Conclusion:

At present, there are more and more coal deep processing enterprises in China, and deep processing of coal can effectively improve the added value of coal, which is a new industry encouraged by current national policies for vigorous development. However, coking wastewater from the coal deep processing industry is difficult to biodegrade due to its high content of chemical organic chemical components. Therefore, the deep treatment of coking wastewater has become an urgent technical problem to be solved in coking plants.

CN

CN