Preface

With the rapid development of the economy, the continuous improvement of residents' living standards, and the strengthening of industrialization, the pollution of the environment caused by the food production process has intensified, and the harm to human health has become increasingly common and serious. Especially, the wastewater discharged from the production process has the characteristics of high concentration of organic pollutants, high color, and large changes in water quality and quantity, making it one of the most difficult industrial wastewater to treat. The treatment of high chromaticity wastewater has always been a challenge in the treatment of wastewater in the food industry. The main sources of high chromaticity wastewater in the food industry are: firstly, during the food production process, chemical reactions produce pigments that eventually enter the wastewater, such as melanin produced by glucose oxidation during soy sauce fermentation; Secondly, during the production process, in order to achieve a good color of the food, edible coloring and dyes are added, such as caramel coloring artificially added during soy sauce blending and fruit green added during green bean production.

1. Common wastewater treatment technologies for the food industry

1.1 Flocculation method

The flocculation method utilizes the adsorption or ion bridging effect of metal hydroxides or organic metal polymers for decolorization, and is most effective for particles with particle sizes ranging from 10-9nm to 10-8nm. The principle of this method is to add a coagulant with charged or polar functional groups to eliminate the electrostatic repulsion between particles in the original system, promote their aggregation and sedimentation, and thus achieve the purpose of separation and decolorization. Common coagulants include inorganic coagulants and polymer coagulants. Inorganic coagulants include aluminum based [mostly mixed solutions of Al2O4 or (NH4) 2SO4], iron based [FeSO4, Fe(2SO4)3 or FeCI3, etc.], as well as acid-base coagulants used to change pH and cause certain substances to settle. Inorganic coagulants have a good effect on the treatment of colored wastewater, but they are too sensitive to pH and can only achieve satisfactory results under the most suitable pH conditions. Polymer coagulants have a larger molecular weight, stronger particle binding ability, lower dosage, faster aggregation speed, and greater adaptability to pH than inorganic coagulants. In addition, patents have shown that using soil as a raw material and activating it at room temperature in inorganic acids can produce products that can be used as coagulants and have decolorization effects on various dyes.

1.2 Adsorption method

Adsorption method is a method of using porous solid materials as adsorbents to adsorb high chromaticity substances in wastewater on their surfaces. Common adsorbents include activated carbon, diatomaceous earth, coke powder, and macroporous adsorption resins. Activated carbon has the characteristics of looseness, porosity, low packing density, and specific surface area, which can efficiently adsorb water-soluble pigments and dyes, but cannot adsorb suspended solids and insoluble dyes. Moreover, the regeneration cost of activated carbon is expensive and is generally used for the treatment of small amounts and low concentrations of wastewater. Boiler slag, steel slag, coke powder, and agricultural waste (such as sugarcane bagasse, peanut shells, etc.) have certain adsorption capacity and can replace activated carbon. The experiments of Luo and Ming et al. showed that using waste coke powder as raw material, through ash removal treatment and chemical modification with ammonium persulfate, methylene blue dye in wastewater can be effectively adsorbed. Macroporous adsorption resin is a high molecular weight polymer with a three-dimensional pore structure inside, and the pore size and specific surface area are relatively large. It has a large specific surface area, high adsorption efficiency, easy washing and regeneration, and has been widely used in high chromaticity food industry wastewater.

1.3 Oxidation decolorization method

Chemical oxidation decolorization refers to the use of oxidizing agents such as chlorine, ClO2, O3, H2O2, HClO4, and hypochlorite to break or change the chemical structure of chromophores in wastewater under certain conditions, thereby achieving the purpose of wastewater decolorization. Oxidation methods include chemical oxidation, photocatalytic oxidation, and ultrasonic oxidation. Although the specific processes are different, the decolorization mechanism is the same. Chemical oxidation is currently a mature method of research, and oxidants generally include Fenton reagent (Fe2+and H2O2), ozone, chlorine gas, sodium hypochlorite, etc.

1.4 Biological decolorization

Biological decolorization is the use of microbial enzymes to oxidize or reduce colored molecules, breaking their unsaturated bonds and chromophores to achieve decolorization.

1.5 Electrochemical decolorization

Electrochemical methods purify wastewater through electrode reactions. According to the electrode reaction mode, electrochemical methods can be divided into internal electrolysis, electrocoagulation and electrocoating, and electro oxidation. The most famous internal electrolysis method is the iron chip method.

1.6 Membrane separation method for decolorization

In the field of wastewater treatment, membrane separation is a technology that uses artificially synthesized or natural polymer films, driven by external energy or chemical potential differences, to selectively separate pollutants in water, thereby purifying wastewater.

2 Haipu Introduction

2.1 Introduction to Haipu Company's Process

The wastewater decolorization and adsorption process developed by Jiangsu Haipu Functional Materials Co., Ltd. removes the vast majority of colored substances in the wastewater by adsorption. The color of the adsorbed water can be reduced to transparency, ensuring subsequent discharge or reuse requirements.

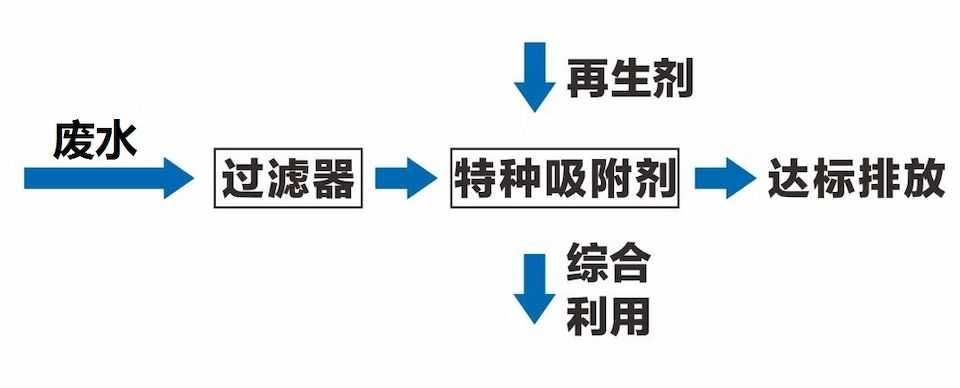

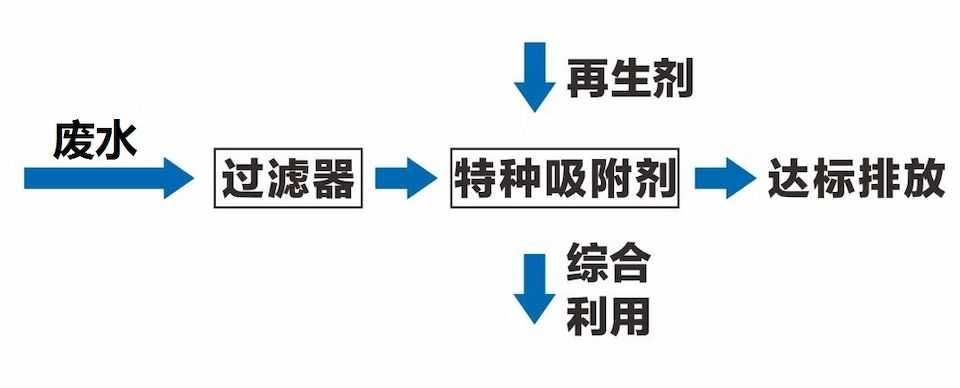

When using Haipu's adsorption process for high chromaticity wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb the colored substances in the wastewater on the surface of the material, significantly reducing the chromaticity of the effluent. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The process flow of wastewater decolorization and adsorption treatment is shown in the following figure.

Figure 1 Process Flow Diagram

2.2 Case Introduction

This newly built wastewater decolorization and adsorption treatment facility has a total designed wastewater treatment capacity of 300 tons per day. The wastewater is high chromaticity wastewater from the factory, with a deep color and high organic content, which cannot meet the stable production needs of the enterprise. Haipu has customized the process design for the wastewater, and the raw water indicators for the wastewater are shown in the table below.

Table 1 Raw Data of Wastewater

| Water volume (m³/day) | Appearance | pH | Chromatic dilution factor | TOC(ppm) |

| 300 | Yellow | 7.91 | 400 | 212 |

The company entrusted Jiangsu Haipu Company to adsorb and treat the wastewater to meet the standards before discharge, and the system operated stably. The wastewater treatment data is shown in Table 2.

Table 2 Data of Wastewater Adsorption Treatment

| Batch | Adsorption flow rate | Adsorption capacity | Dilution ratio of inflow water | Dilution ratio of effluent |

| 1 | 2BV | 30BV | 400 | 40 |

| 2 | 2BV | 30BV | 400 | 20 |

| 3 | 2BV | 30BV | 400 | <10 |

| 4 | 2BV | 30BV | 400 | 20 |

| 5 | 2BV | 30BV | 400 | <10 |

Figure 2 Appearance of effluent (left) and raw water (right)

3. Conclusion

Although using physical, chemical, and biochemical methods as basic treatment units to treat certain dye wastewater can achieve certain treatment effects. But so far, food wastewater is still one of the industrial wastewater that is difficult to treat. It is necessary to consider not only the progressiveness of treatment technology, but also the feasibility of infrastructure investment and operating costs. Therefore, the main focus of food wastewater treatment technology is on the following four aspects: efficiency, adaptability, economy, and cleanliness.

CN

CN