Background Introduction

1. Taking the upgrading of biochemical effluent in the coking industry as an example

The composition of coking wastewater treatment is complex, usually containing a large amount of stable organic compounds such as phenols, heterocycles, polycyclic aromatic hydrocarbons, etc. It is a typical high pollution and difficult to degrade industrial wastewater. The effluent from this type of coking wastewater treated by biochemical methods contains residual organic matter, which still fails to meet increasingly strict environmental requirements for water quality indicators such as COD and ammonia nitrogen. In addition to small molecule organic compounds produced by biological metabolism, there are also some difficult to degrade aromatic and heterocyclic organic compounds, including organic compounds containing double bonds, hydroxyl groups, amide groups, nitro groups and other chromophores, and most of them also contain - NH2, - OR, - OH and other chromophores, making the color of coking wastewater still very high. Therefore, further in-depth processing is needed.

2. Taking the biochemical effluent of cassava alcohol fermentation industry as an example

The wastewater produced by cassava fermentation for alcohol production mainly contains sugars, proteins, vitamins, residual sugars, short fibers, and ammonium salts. After biochemical (microbial metabolism) treatment, the composition of the wastewater becomes very complex. The main components are nitrogen-containing organic compounds containing chromophores that are difficult to biodegrade, water-soluble small molecule organic compounds, ammonium salts, etc. These pollutants are the main contributors to COD and chromaticity in biochemical effluent, among which nitrogen-containing organic compounds not only produce COD but also cause high chromaticity problems, which are common issues in biochemical effluent.

Our company's biochemical effluent upgrading technology, with adsorption process as its core, is a special adsorbent and its application process developed specifically for the upgrading or reuse needs of biochemical treated effluent. This adsorbent belongs to a special adsorption resin, and its pore structure, specific surface area, and functional groups are artificially controlled and designed based on the common problems of biochemical wastewater. The leader of the relevant technical team has worked for several well-known foreign companies, responsible for the research and development of products, technologies, and processes related to wastewater deep treatment and reuse. The relevant technology has been industrialized and applied in many large steel and coking enterprises in China. At present, our company's related products and technologies are further upgraded based on previous related technologies, with better performance, easier operation, and lower operating costs.

The following table provides a comprehensive comparison of the main methods for deep treatment of wastewater.

Table 1 Comparison of Advanced Wastewater Treatment Technologies

| Technology | Advantages and disadvantages |

| Fenton oxidation | 1. The introduction of a large amount of iron ions into the produced water makes it difficult to control the color of the effluent, resulting in a large amount of sludge and high sludge treatment costs. The overall operating cost of the system is also high.

2. The cost of equipment maintenance is high, especially when the hardness of the air flotation effluent water in this project is relatively high. Using Fenton oxidation will result in serious equipment scaling problems.

3. It is difficult to control because the optimal ratio of hydrogen peroxide to ferrous sulfate needs to be determined through orthogonal experiments, and is influenced by the pH value of the reaction, the length of the reaction time, and the degree of stirring and mixing, making it difficult to control the ratio.

4. Fenton treatment is highly corrosive, and if the water quality fluctuates, modifying sewage treatment parameters can be cumbersome, affecting treatment efficiency. |

|

|

|

| Biochemical technology | 1. Biochemical tailwater is the effluent that has been treated with microbial technology, and the residual organic matter, color, etc. are substances that cannot be metabolized by microorganisms. Generally, the BOC/COD ratio is low and the biodegradability is poor. Further biochemical treatment is inefficient.

2. Biochemical technology has a significant amplification effect, a long debugging cycle, and many uncertain factors that affect the treatment effect.

3. Large land occupation, high investment in the entire system, unstable operating performance, and high operating costs.

The humic acid, colloidal substances, microbial particles, and microbial remains generated by the biochemical system affect subsequent RO deep treatment and water reuse. |

|

|

|

Double membrane method (ultrafiltration+reverse osmosis) or triple membrane method (ultrafiltration+nanofiltration+reverse osmosis) | 1. It can achieve standard discharge of biochemical wastewater or water reuse, and the effluent is colorless. But at the same time, a large amount of high chromaticity and high COD concentrated water (concentrated water 30-55%) is produced. 2. The system investment is relatively large, and nanofiltration and reverse osmosis are easily contaminated by wastewater. The cost of replacing membrane components is high, and the overall operating cost of the system is high. |

| Special adsorption technology | 1. Special adsorbents have strong decolorization performance, high removal efficiency for colored organic matter, and can remove other pollutants such as COD while decolorizing.

2. It can achieve stable and compliant discharge of biochemical wastewater, remove large molecular organic compounds generated by the biochemical system, and provide guarantees for the subsequent reuse of water in RO membranes.

The system has a small footprint, low investment, stable operation, easy operation, and low operating costs. |

|

|

Technical features

1. Special adsorbents for deep treatment of biochemical wastewater have high decolorization efficiency and no color reversal. Good removal efficiency and stable performance for COD and other pollutants. At the same time, it has a high removal efficiency for large molecular organic compounds such as humic acid and colloidal substances generated by the biochemical system, providing a guarantee for the subsequent reuse of water in RO membranes.

2. This adsorption process mainly involves physical adsorption, with mild conditions and low industrial scaling up benefits. In pilot or industrial scaling up, the treatment effect is often better than in small-scale experiments due to the denser adsorbent bed and smaller wall flow effect.

3. Simple process, easy operation, low labor intensity, small footprint, and low investment. Low operating costs, stable and reliable treatment effects, and can withstand certain water quality fluctuations and impacts.

4. Mild usage conditions, long equipment lifespan, simple maintenance, and minimal subsequent investment. This process produces no hazardous waste and no secondary pollution, making it a green and environmentally friendly solution.

Process route

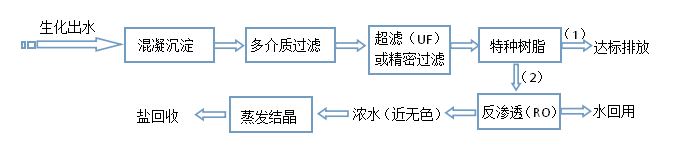

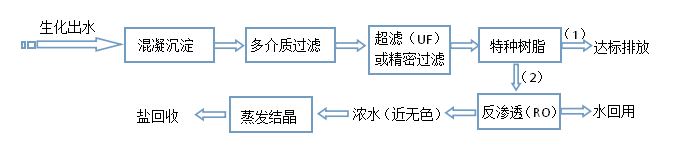

Figure 1 Special adsorption deep treatment process

Application cases

Case 1: Biochemical tail water from Jiangsu Light Factory, treatment requirements, color<80 mg/L. The water quality before and after treatment is shown in the table below. Compared with the original oxidation scheme, the treatment cost is reduced by half.

Table 2 Comparison of Raw Water and Outlet Water

| Water volume

(m³/day) | COD

(mg/L) | Ammonia nitrogen

(mg/L) | Total nitrogen

(mg/L) | Chroma |

|

| Raw water | 7000 | ~500 | ~30 | ~100 | ~600 |

| Effluent | 7000 | 65 | 5 | 20 | 50 |

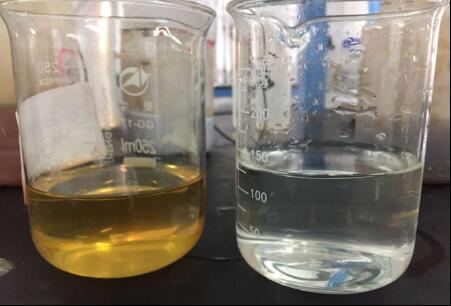

Figure 2: Raw water (left) and final effluent (right)

Case 2: A coking wastewater treatment facility in Shandong Province has been upgraded to meet treatment requirements, with effluent meeting discharge standards. The water quality before and after treatment is shown in the table below.

Table 3 Comparison of Raw Water and Outlet Water

| COD (mg/L) | pH | Appearance |

|

| Raw water | ~300 | 8.2 | Pale brown |

| Effluent | 40 | 7.3 | Colourless |

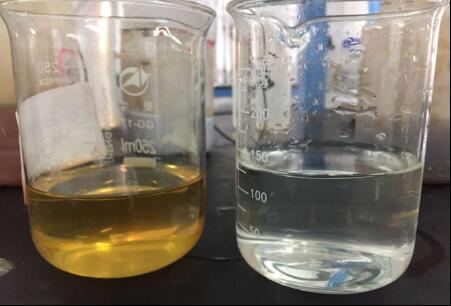

Figure 3: Raw water (left) and effluent (right)

Project site

Figure 4 Project Site

Application fields

1. Biochemical effluent COD, ammonia nitrogen, total phosphorus, chromaticity, etc. from industries such as coking, printing and dyeing, fermentation, etc. have been upgraded.

2. Deep treatment of biochemical wastewater and reuse of reclaimed water in other industries.

CN

CN