The electroplating industry is an indispensable part of the national economy, involving national defense, industry, and daily life. However, the wastewater generated by electroplating is highly toxic and poses a threat to soil, animal and plant growth. It is necessary to strictly treat the wastewater to meet discharge standards. In industry, electroplating processes generate a large amount of heavy metal wastewater during the treatment process, which can cause serious pollution to the environment. Therefore, electroplating wastewater treatment is crucial. Below, Haipu will provide a detailed introduction to the characteristics and treatment methods of electroplating wastewater, hoping to be helpful to you.

Due to the need to add a certain amount of various chemicals in the electroplating production process and wastewater treatment process. After electroplating wastewater treatment, it is recycled and reused. The reused water can only be reused as production line water after desalination, without reducing the total salt content in the environment. The concentrated solution from resin exchange and reverse osmosis processes still returns to the ground.

Current situation and challenges of electroplating wastewater treatment:

When electroplating wastewater contains more than one pollutant, it is generally classified according to one of the pollutants. When there are several process methods for the same plating method, it can also be further divided into different categories according to different processes, such as pyrophosphate copper plating wastewater, copper sulfate copper plating wastewater, etc. Therefore, the process of electroplating wastewater is also diverse.

Chemical precipitation method:

It is a relatively economical and effective method in the treatment of electroplating wastewater. Due to its mature technology, simple operation and management, it can simultaneously remove multiple metals from electroplating wastewater, and therefore has been widely used. Chemical agents are added to wastewater to convert heavy metal ions into insoluble heavy metal compounds, which then precipitate and separate from the wastewater, achieving the goal of removal. The precipitation method is divided into three types: neutralization precipitation method, sulfide precipitation method, and chelation precipitation method

Oxidation method:

By adding oxidants, toxic substances in electroplating wastewater are oxidized into non-toxic or low toxic substances, mainly used to treat CN -, Fe2+, Mn2+low valence ions and various organic compounds that cause color, odor, and pathogenic microorganisms in wastewater. When treating cyanide containing wastewater, hypochlorite is commonly used to oxidize the cyanide ions under alkaline conditions, decomposing them into low toxicity cyanates, which are then further degraded into non-toxic carbon dioxide and nitrogen.

Chemical reduction method:

The most typical application of chemical reduction method in the treatment of electroplating wastewater is the treatment of chromium containing wastewater. The method involves adding reducing agents such as FeS04, NaHS03, Na2S03, S02, or iron powder to the wastewater to reduce Cr (VI) to Cr (III), and then adding NaOH or lime milk for precipitation and separation. The advantages of this method are simple equipment, low investment, and large processing capacity, but it is necessary to prevent secondary pollution caused by sediment and sludge.

Air flotation method:

As a technology for treating electroplating wastewater, it is a new process developed in recent years. The basic principle is to use a high-pressure water pump to pressurize water to several atmospheres and inject it into a dissolution tank, mixing air and water into dissolved air and water. The dissolved air and water enter the water tank through a dissolved air release device. Due to sudden pressure reduction, the air dissolved in the water forms a large number of microbubbles, which adhere to the condensed matter generated by the initial treatment of electroplating wastewater, making its relative density lower than that of water and floating to the surface as floating slag to be discharged, thereby purifying the wastewater.

Biological treatment: Biological treatment is a new technology for treating electroplating wastewater. Some microbial metabolites can change the valence state of heavy metal ions in wastewater. At the same time, the microbial community itself has strong biological flocculation and electrostatic adsorption effects, which can adsorb metal ions. After solid-liquid separation, heavy metals enter the sludge cake, thereby enabling wastewater to meet discharge or reuse standards.

Biological adsorption method:

Any derivative prepared from an object or organism that has the ability to separate metals from a solution is called a biosorbent. Biological adsorbents mainly consist of bacterial cells, algae, and some extracts. The adsorption mechanism of microorganisms on heavy metals depends on many physical and chemical factors, such as light, temperature, pH value, heavy metal content and chemical form, the presence of other ions, chelating agents, and pre-treatment of adsorbents. Biological adsorption technology has certain advantages in treating heavy metal pollution. Under low concentration conditions, biological adsorbents can selectively adsorb heavy metals and are less affected by the interference of calcium and magnesium ions in aqueous solutions. This method has high processing efficiency, no secondary pollution, and can effectively recover some precious metals. However, the growth environment of organisms is not easy to control, and they often suffer from massive poisoning and death due to changes in water quality.

Biological flocculation method:

Biological flocculation is a method of pollutant removal that utilizes microorganisms or metabolites produced by microorganisms for flocculation and sedimentation. Microbial flocculants are natural high molecular weight substances produced by microorganisms themselves that have efficient flocculation effects. They have high charges or strong hydrophilicity and hydrophobicity, and can adsorb multiple colloidal particles simultaneously with particles through ionic bonds, hydrogen bonds, and van der Waals forces, creating bridging phenomena between particles and forming a network like three-dimensional structure that precipitates. At present, there are about a dozen varieties of bioflocculants that have flocculation effects on heavy metals. The amino and hydroxyl groups in bioflocculants can form stable chelates with heavy metal ions such as Cu2+, Hg2+, Ag+, Au2+and precipitate. This method for treating wastewater has the characteristics of safety, convenience, non toxicity, no secondary pollution, wide flocculation range, high flocculation activity, fast growth, extensive flocculation conditions, and is mostly not affected by ion strength, pH value, and temperature. It is easy to achieve industrialization.

Biochemical method:

Biochemical methods involve direct chemical reactions between microorganisms and metal ions to convert soluble ions into insoluble compounds for removal. Its advantages are: strong selectivity, large adsorption capacity, and no use of chemical agents. The high metal content in sludge significantly reduces secondary pollution, and heavy metals in sludge are easy to recover with high recovery rates. But its disadvantage is that the reaction efficiency between functional bacteria and metal ions in wastewater is not high, and the consumption of culture medium for cultivating bacterial strains is large, resulting in high treatment costs.

Industry customer demand

Electroplating wastewater cannot be directly discharged through chemical precipitation method, so it must be deeply treated. The traditional chemical precipitation method combined with the adsorption method developed by Haipu functional materials can achieve the treatment effect. The requirements of electroplating wastewater enterprise customers for wastewater treatment include the following three points:

(1) Efficiently and stably remove heavy metals from wastewater below emission limits;

(2) Low investment cost, low operating cost, and convenient equipment operation and maintenance;

(3) Advanced and reliable technology, with no secondary pollution.

Introduction to Haipu customized process

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

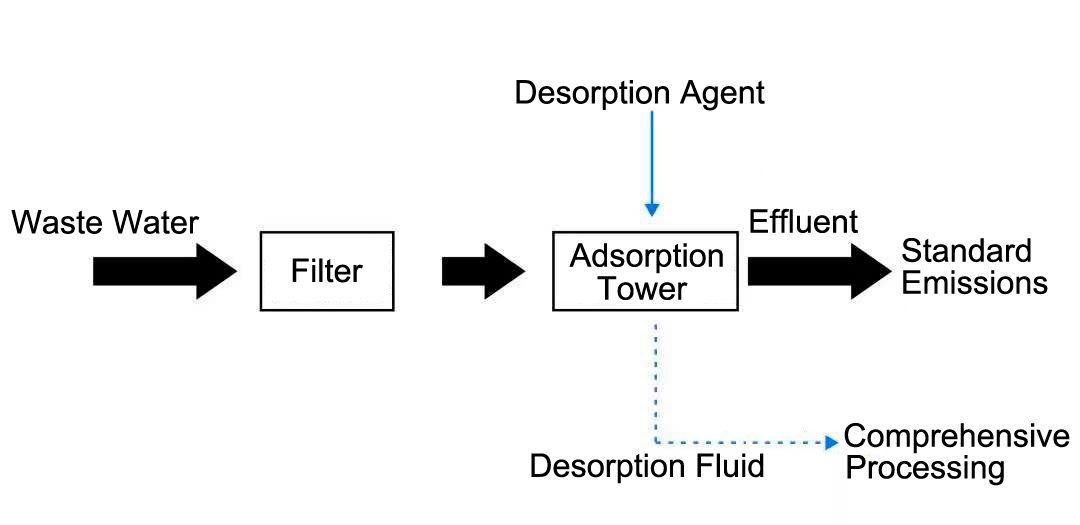

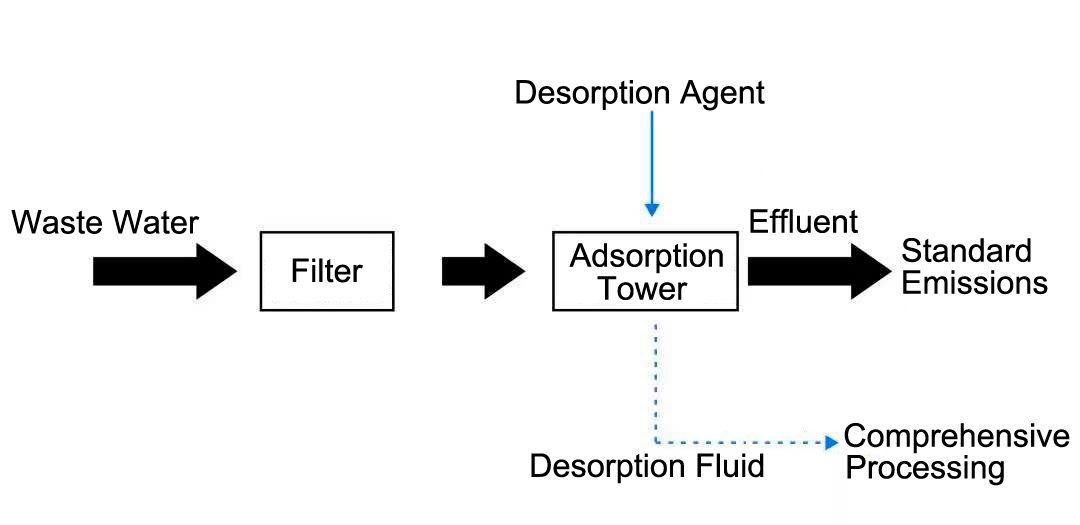

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to be regenerated. This process is continuously repeated. The conventional process of treating wastewater by adsorption method is shown in the following figure.

Conventional process diagram for adsorption treatment of wastewater

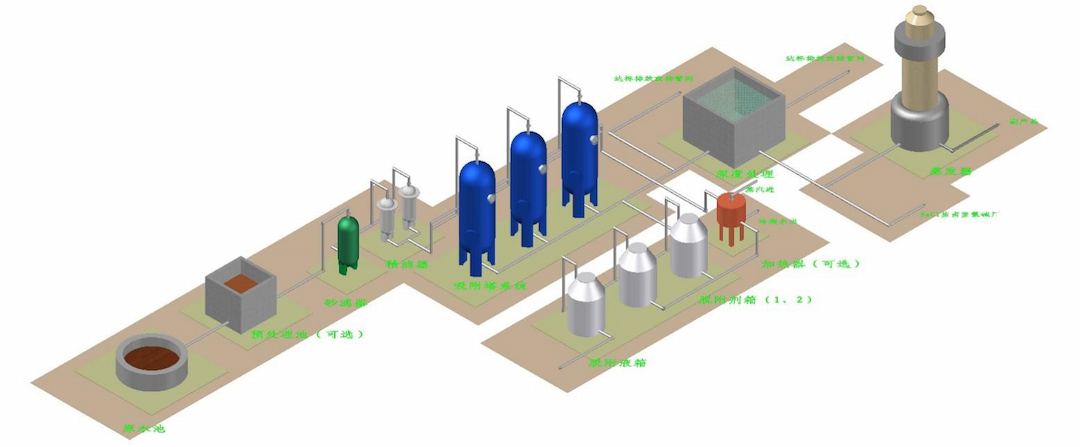

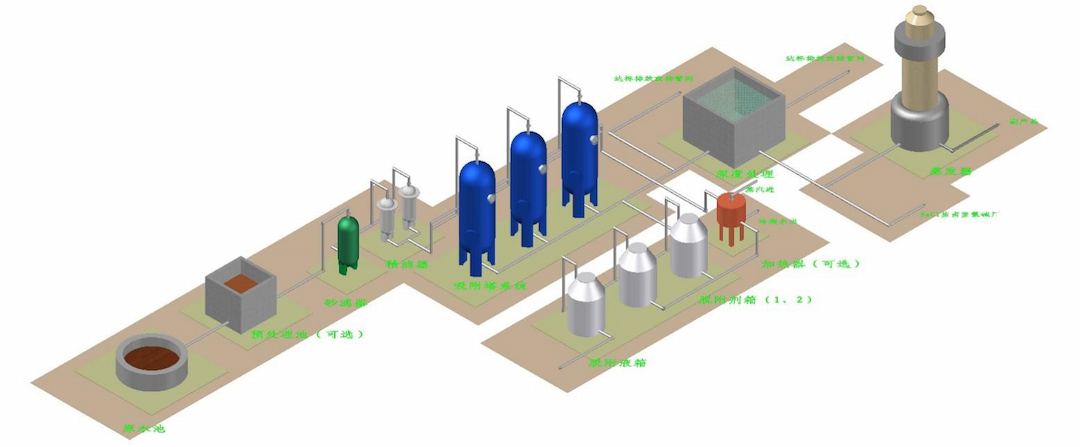

When using Haipu's adsorption process to treat pyridine wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb heavy metals in the wastewater on the surface of the material, ensuring that the effluent discharge of heavy metals continues to meet the standard. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The adsorption treatment process flow of nickel containing wastewater is shown in the following figure.

Process flow of adsorption treatment for heavy metal wastewater

Process treatment effect

The adsorption process is used to treat heavy metal wastewater, which can effectively remove heavy metals from the wastewater. The specific treatment data is shown in the table below:

Wastewater Adsorption for Pyridine Removal Data

| Heavy Metal Content in Raw Water | Heavy Metal Content in Treated Water | Compliance Rate |

| 1.5 mg/L | 0.056mg/L | 100% |

| 1.9mg/L | 0.069 mg/L | 100% |

| 1.7 mg/L | 0.051 mg/L | 100% |

A certain enterprise in Suzhou requires that the nickel content in the treated wastewater be less than 0.1mg/L and the total chromium be less than 0.5mg/L. The experimental treatment effect shows that using adsorption treatment can stabilize the nickel content in the wastewater to be less than 0.1mg/L and the chromium content to be less than 0.5ppm. While ensuring that the customer's requirements are met, a certain safety margin is left, which can effectively prevent the water quality fluctuation of the incoming wastewater from causing the effluent to not meet the standard. The effect is shown in the following figure.

The production process of the enterprise generates 200 tons of nickel containing wastewater and 200 tons of chromium containing wastewater every day. After chemical precipitation, the nickel chromium in the wastewater cannot meet the discharge requirements. The enterprise requires that the treated nickel must be discharged 100% to meet the standard. The experimental results show that adsorption can meet the requirements of the enterprise.

Core advantages of craftsmanship

At present, the treatment methods for electroplating heavy metal wastewater have their own shortcomings in terms of treatment effectiveness and operating costs. The adsorption method can effectively remove heavy metals from wastewater below the discharge limit, making it an economical and effective method for treating heavy metal wastewater. Its advantages include the following:

(1) Stable and compliant emissions can effectively alleviate the environmental pressure on enterprises.

(2) Conduct experiments on sampling samples of wastewater generated on the enterprise site, based on technology, and design adsorption processes based on experiments. The matching degree between wastewater and processes is 100%.

(3) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs.

(4) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install.

(5) Advanced and mature technology, no secondary pollution, strong technical support, and rich engineering application experience.

Case Introduction: A 2500t/d Nickel containing Wastewater Deep Treatment Project of a Electroplating Enterprise in Jiangsu Province:

The company uses our adsorption process to treat the nickel containing wastewater generated during its production process. Experiments have shown that the nickel content in the wastewater has decreased from the original 2mg/L to below 0.1mg/L. The nickel content in the treated wastewater is particularly low and can be directly discharged or reused, reducing the environmental pressure on the enterprise.

On Site Application of Adsorption Tower

CN

CN