1. Characteristics of domestic waste acid

Acid is widely used as a cleaning agent, corrosive agent, or catalyst in industries such as metallurgy, machinery, and chemical engineering. When impurities in the acid reach a certain concentration, it cannot continue to be used in production and becomes waste acid. China is the world's largest producer and consumer of acid, consuming 97.7 million tons of sulfuric acid in 2015. If the utilization rate is 75%, the annual production of waste sulfuric acid will reach 20 million tons. Waste acid has a large production capacity and hazardous characteristics such as corrosiveness, toxicity, and reactivity, which pose a great threat to the environment. Improper disposal can cause serious resource waste.

2. Current situation of waste acid treatment

At present, waste acid treatment processes include neutralization method, diffusion dialysis method, evaporation method, spray roasting method and adsorption method. The neutralization method has a simple process and low equipment investment, but it is prone to producing a large amount of heavy metal waste residue, exceeding the standard for effluent, consuming a large amount of alkali, and cannot be utilized as a resource; The evaporation method has a simple process, and the separated crystals can be used as raw materials. However, the equipment is prone to corrosion and requires high anti-corrosion requirements. At the same time, it has high energy consumption, multiple equipment, and complex operation; The spray roasting method can recover free acid and combined acid from waste acid at the same time, but the investment is large, the floor area is large, and the equipment has high corrosion resistance requirements, large energy consumption, complex process, and heavy workload of equipment maintenance and operation; The diffusion dialysis method can achieve the separation of acid and metal impurities, with simple operation and low energy consumption, but with small processing capacity, large equipment investment, and low acid recovery concentration.

Adsorption method is an important method for treating pollutants, and the performance of adsorbents has a huge impact on the adsorption separation effect, operation, and investment costs. At present, adsorbents mainly include polymer resin adsorbents, activated carbon materials, etc. Activated carbon adsorbents have good adsorption effects, but activated carbon belongs to broad-spectrum adsorbents with poor adsorption selectivity and poor adsorption and regeneration stability. Resin adsorbents have a large specific surface area, controllable microporous structure, and good thermal stability. They have been widely used in fields such as wastewater and exhaust gas treatment, which can solve environmental problems and recover resources. Therefore, developing efficient adsorbents for waste acid treatment is an important aspect of achieving waste acid treatment and resource utilization. At present, the special adsorbent used in industry is expensive and has a short service life, which limits its application. Developing efficient, long-lasting, and low-cost waste acid treatment adsorbents and achieving industrial production is of great significance.

3. Core advantages of Haipu waste acid treatment system

(1) By functionalizing polymer based nanoadsorbents, special functional groups are bonded to the inner and outer surfaces of the polymer, exhibiting excellent selectivity towards acid components;

(2) By suspending double bonds in the adsorbent matrix and conducting crosslinking reactions, the crosslinking degree of the adsorbent polymer matrix is further improved, and its expansion rate in acidic environments is controlled to ensure the mechanical strength of the material, while increasing the specific surface area and pore volume of the material;

(3) By surface passivation modification, the antioxidant performance of the adsorbent in acidic wastewater is improved.

4. Introduction to Haipu Customized Process

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

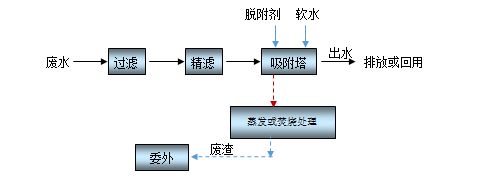

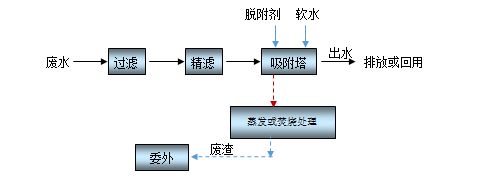

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to regenerate. This process is continuously repeated. The conventional process diagram for treating wastewater by adsorption method is shown in Figure 4-1.

Figure 4-1 Conventional Process Diagram for Adsorption Treatment of Wastewater

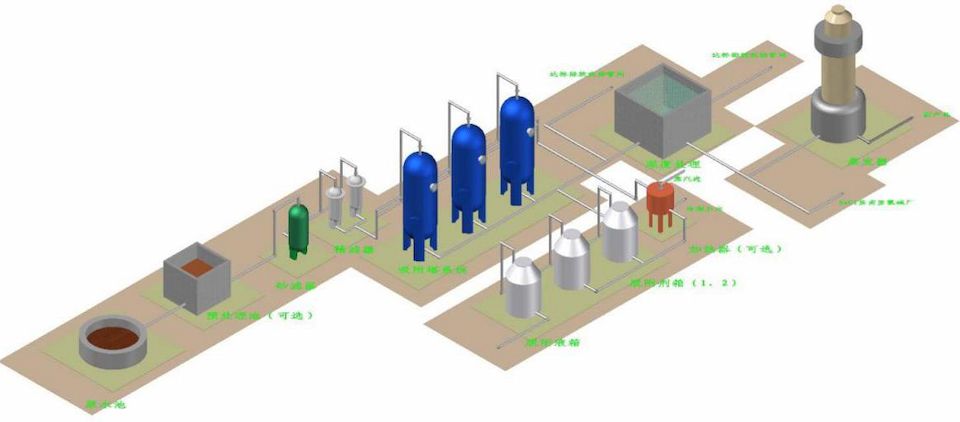

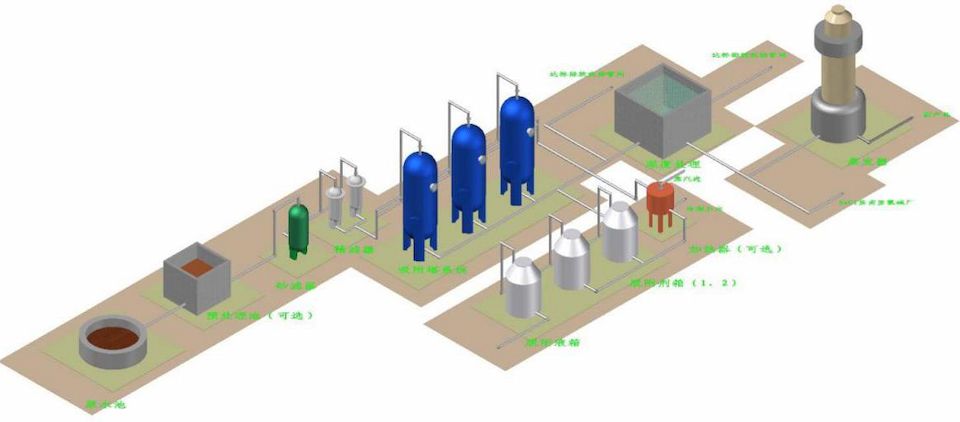

When using Haipu's adsorption process to treat waste acid, the waste acid is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb organic matter in the wastewater on the surface of the material, so that the effluent COD and other indicators can continue to meet the standard discharge. After adsorption saturation, first use a desorption agent to desorb the organic matter on the adsorbent material, transfer the organic matter into the desorption solution, and then rinse the residual desorption agent on the surface of the adsorbent material with a small amount of soft water. The desorption solution is then evaporated or subjected to other treatments. The washing solution contains trace amounts of adsorbed substances and can be used as dilution water for dilute alkali. The adsorbed effluent is wastewater with COD lower than the discharge limit, which can be directly discharged or reused in the front-end production line. The process flow of waste acid adsorption treatment is shown in Figure 4-2.

Figure 4-2 Waste Acid Adsorption Treatment Process Flow

5. Process treatment effect

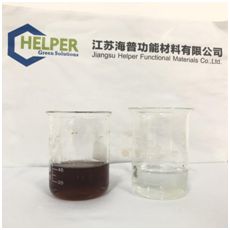

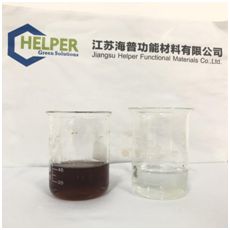

The use of adsorption technology to treat waste acid can effectively remove COD and chromaticity from wastewater, and is suitable for waste acid oil removal, waste acid COD removal, waste acid decolorization, etc. The specific treatment data is shown in Tables 5-1 and 5-2.

Table 5-1 COD removal data by waste acid adsorption

| Name | COD(mg/L) | Acidity (calculated as sulfuric acid) | Colour |

| Device water inlet | ~50000 | 20~70% | Dark brown |

| Device effluent | ≤2500 | 20~70% | Transparent and colorless |

Table 5-2 Recovery of sulfonated para esters from waste sulfuric acid

| Name | COD(mg/L) | Acidity (calculated as sulfuric acid) | Rate of recovery | Colour |

| Device water inlet | ~28480 | 15% |

| Dark brown |

| Device effluent 1 | 7260 | 15% | 75% | Transparent and colorless |

| Device effluent 2 | 6340 | ~ | 78% | Transparent and colorless |

| Device effluent 3 | 6940 | ~ | 77% | Transparent and colorless |

Figure 1 Sulfonated para ester waste acid (left) and adsorbed effluent (right)

6. Core advantages of the process

(1) Efficiently removing organic matter from waste acid, special adsorption materials have large adsorption capacity, high concentration ratio, and low investment;

(2) The processed waste acid can be reused in production, achieving the resource utilization of waste acid;

(3) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs;

(4) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install;

(5) Advanced and mature technology, with strong technical support and rich engineering application experience.

CN

CN