Current situation of fluoride removal

In industry, wastewater discharged from industries such as fluorine-containing ore mining, metal smelting, aluminum processing, coking, glass, electronics, electroplating, fertilizers, pesticides, lithium batteries, etc. often contains high concentrations of fluoride.

So, the country has also introduced strict institutional standards for monitoring and discharging fluorine-containing wastewater.

| Standard | Fluoride ion concentration, mg/L | Remarks |

| GB 3838-2002 Surface Water Environmental Quality Standards | 1 | Surface Water I, Surface Water Ⅱ, Surface Water Ⅲ |

| 1.5 | Surface Water IV, Surface Water V |

| GBS749-2006 Sanitary Standards for Drinking Water | 1 | Emission limits |

At present, the defluorination processes on the market, such as precipitation, electrodialysis, ion exchange, etc., all have their own problems. Finding an efficient and practical defluorination product and process is particularly important for enterprises with defluorination needs.

Product Introduction

To meet the needs of enterprises for efficient, simple, and low-cost treatment of fluorine-containing wastewater, the research team of Haipu Functional Materials has developed an adsorption resin product based on the characteristics of typical industry wastewater quality and treatment processes - Haipu defluorination resin.

Haipu defluorination resin products have high selectivity for defluorination, strong anti-interference ion resistance, stable performance, and can be used repeatedly for a long time.

Haipu's multiple defluorination resin products can meet the requirements for defluorination of fluorine-containing materials in waste battery recycling, standard treatment of various fluorine-containing wastewater, and defluorination of drinking water.

Product parameters

This defluorination resin product has high defluorination selectivity and minimal interference from other coexisting anions. After adsorption defluorination, the fluoride ion concentration in the effluent is less than 1 mg/L.

*Application of Fluorinated Resin Products in Practical Projects

*Application of Fluorinated Resin Products in Practical Projects

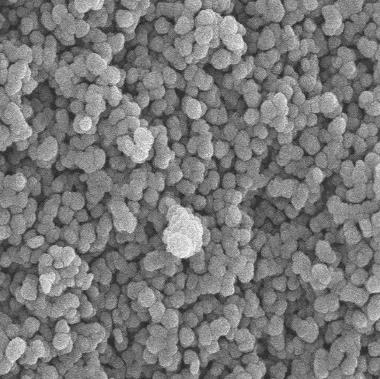

HPF4000 utilizes surface functional groups of polymer materials to pre enrich fluoride ions, and then removes fluoride through nano materials for fluoride removal within the polymer. Therefore, HPF4000 has high selectivity and adsorption accuracy for fluoride ions.

Product and its supporting process characteristics

At present, there are several widely used defluorination technologies in the corresponding market fields, including:

Fluoride Removal Application Technology

| Method | Advantage | Shortcoming |

| Precipitation method | Simple process, suitable for the treatment of high concentration fluorine-containing wastewater | High investment volume, difficult to meet standards; large mud production and difficult dehydration |

| Ion exchange method | Simple operation and management, suitable for low to medium concentration fluoride water treatment | High cost of ion exchange resin and high cost of regeneration |

| Electrodialysis method | Simple preprocessing, suitable for small-scale defluorination systems | High infrastructure and operating costs, high requirements for operation and maintenance personnel |

| Nanofiltration/reverse osmosis method | Ro has a very high fluoride removal rate and is not affected by coexisting ions | High investment and operating costs; there is a problem with concentrated water treatment, and the operation is complex |

Compared with the above-mentioned defluorination technologies, Haipu defluorination resin products and their supporting processes have the following points:

Long service life of products: Haipu defluorination resin products have high mechanical strength, good stability, stable regeneration performance, and long service life.

System intelligent control: PLC fully automatic operation, high degree of automation, simple operation.

Purchasing high-quality big brands: selecting top domestic and foreign brands for electrical appliances and instruments

Low overall operating costs: Low operating costs, stable and reliable treatment effects, and can withstand water quality fluctuations and impacts

Low difficulty in process installation: The process equipment is reliable and stable, and the modular design is also easy to maintain and manage

Product application effect

Haipu defluorination resin products and their supporting combination processes have helped multiple customers meet their treatment needs for fluorine-containing wastewater.

01

Application Case 1

A company produces 100 tons/day of wastewater with a pH of 9.5 and a fluoride content of 10.5mg/L during the production process, with a treatment requirement of ≤ 1mg/L.

For this purpose, our company uses defluorination resin products to adsorb and separate fluoride ions in drinking water. The fluoride content after adsorption treatment is significantly reduced, which meets the customer's requirements for the treatment of this indicator.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 10.5mg/L | 0.29mg/L | 97.24% |

| 10.5mg/L | 0.17mg/L | 98.38% |

| 10.5mg/L | 0.15mg/L | 98.57% |

| 10.5mg/L | 0.11mg/L | 98.95% |

02

Application Case 2

A company produces wastewater with a fluoride content of around 300 mg/L, and requires that the fluoride content in the treated wastewater be less than 10.0 mg/L.

Our company's fluorine removal resin product was used for treatment in the experiment, and the removal rate of fluoride ions in the wastewater remained stable at over 96%. The fluoride content in the effluent was less than 10.0 mg/L.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 300mg/L | 9.1mg/L | 96.97% |

| 300mg/L | 9.5mg/L | 96.83% |

| 300mg/L | 9.4mg/L | 96.87% |

03

Application Case 3

A mining enterprise produces groundwater with a fluoride content of about 1.4 mg/L during the process of mining ore. The enterprise requires that the fluoride content in the treated wastewater be less than 0.5 mg/L.

The experimental treatment effect shows that using Haipu nano hybrid fluoride removal adsorbent products for treatment, the fluoride ion removal rate in wastewater remains stable at over 92%, and the fluoride content in effluent can be controlled below 0.5 mg/L.

Keeping a certain safety margin while ensuring compliance with customer requirements can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 1.4mg/L | 0.04mg/L | 97.14% |

| 1.4mg/L | 0.10mg/L | 92.86% |

| 1.4mg/L | 0.08mg/L | 94.28% |

CN

CN