Excessive discharge of electroplating wastewater has always been a pain point for manufacturing enterprises Is meeting the standards for electroplating wastewater treatment also a way for companies to urgently seek new and effective processes? How to treat electroplating wastewater to meet the standard? Jiangsu Haipu's editor will share their experience with you.

Electroplating in manufacturing enterprises is an indispensable component of high-end technology and modern industrial systems, applied in aerospace, electronic communication and computer, weapon equipment, petrochemicals, shipbuilding, hardware tools and machinery manufacturing.

This process helps to improve the corrosion resistance, wear resistance, and decorative performance of the product, thereby significantly increasing the added value of the product. It is often used to prepare many important mechanical and electronic components.

*The image is sourced from the internet

At present, China has become a major electroplating country. However, many acid, alkali, heavy metal ions, and even cyanide and other toxic substances are used in the electroplating process, which will dissolve in water.

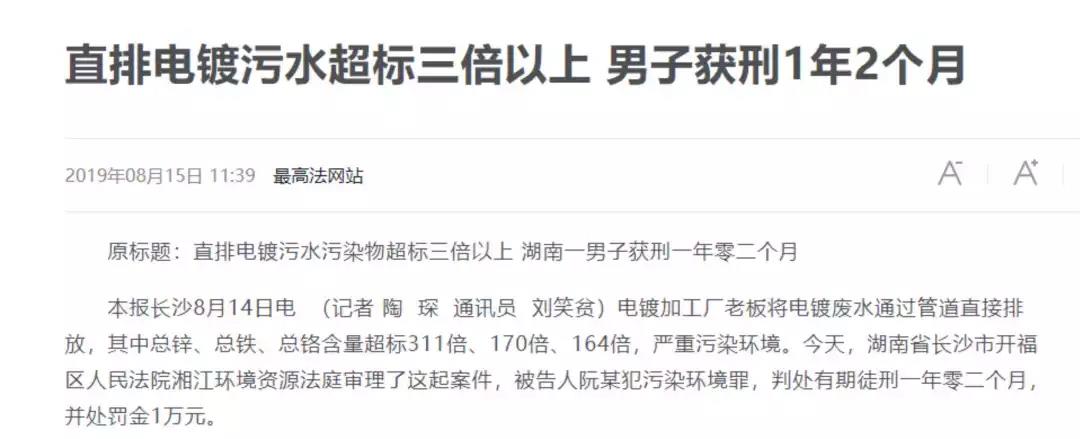

If the wastewater generated during the electroplating process is directly discharged, it will cause serious water pollution. In order to reduce the environmental pollution caused by electroplating wastewater, countries around the world have established standards for the discharge of electroplating pollutants.

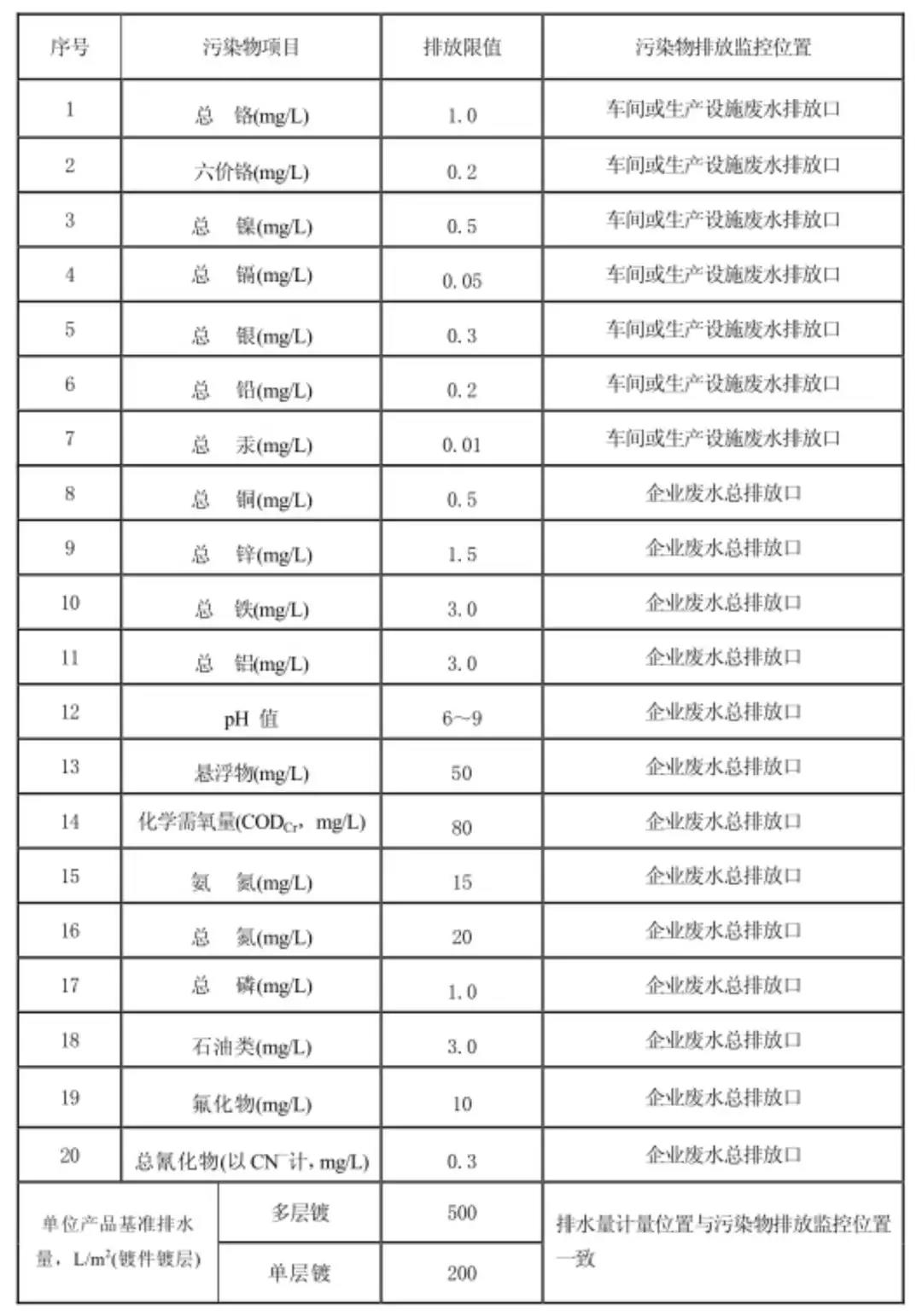

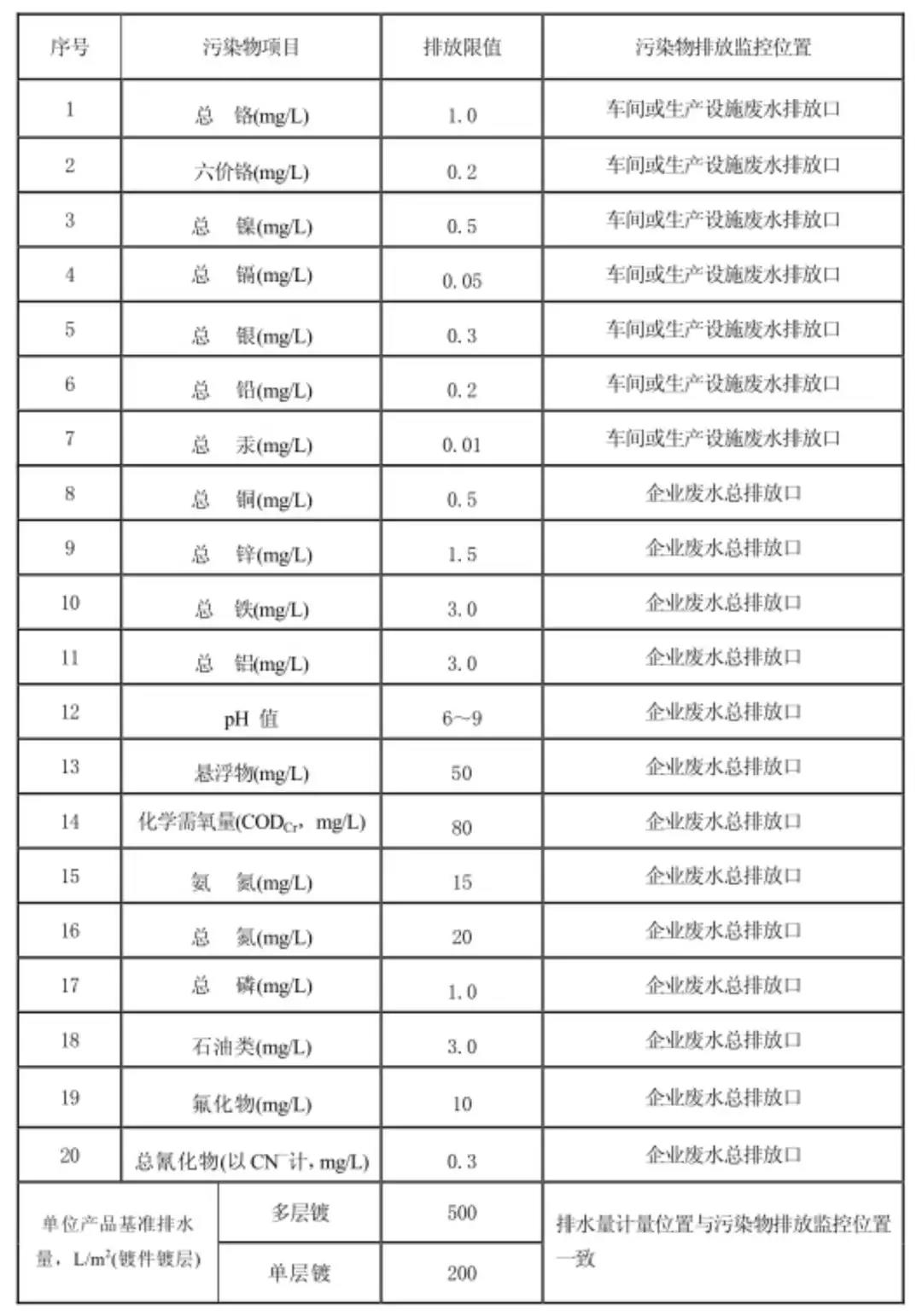

The "Emission Standards for Electroplating Pollutants" (GB 21900-2008) issued by the Ministry of Environmental Protection in 2008 stipulated the emission limit requirements for 20 wastewater pollutant indicators (including 7 indicators such as total chromium, hexavalent chromium, total nickel, total cadmium, total silver, total lead, and total mercury required to be monitored at the wastewater discharge outlet of workshops or production facilities, and 13 indicators such as total copper, total zinc, total iron, total aluminum, pH, suspended solids, chemical oxygen demand, ammonia nitrogen, total nitrogen, total phosphorus, petroleum, fluoride, and total cyanide compounds required to be monitored at the discharge outlet).

Starting from August 1, 2008, newly established enterprises and July 1, 2010, existing enterprises will implement the following wastewater pollutant discharge limits.

Pollutants that are prone to excessive discharge in electroplating wastewater.

At present, according to feedback from electroplating companies and environmental protection departments, the pollutants that electroplating companies are prone to exceeding standards mainly include total nickel, total copper, total zinc, total chromium, chemical oxygen demand, total phosphorus, total cyanide and other indicators.

The pollutants that are prone to exceeding the standard in electroplating production can be divided into two categories based on their physical and chemical properties: metal and non-metal. Total copper, total zinc, total chromium, and total nickel belong to the metal pollutant indicators, while chemical oxygen demand, ammonia nitrogen, total phosphorus, total cyanide, and other pollutants belong to the non-metal pollutant indicators. Pollutants in the same category have similar physical and chemical properties, resulting in similar reasons for exceeding the standard.

In recent years, the factors involved in the incidents of excessive emissions by electroplating enterprises are basically the above-mentioned situations.

Haipu assists electroplating enterprises in meeting wastewater discharge standards.

Through years of independent research and development, Haiping has achieved a series of adsorption products in areas such as ion exchange technology, adsorption technology, and hybrid technology of nano inorganic materials. These products have been successfully applied in the fields of environmental protection and resource recycling.

In response to the pollutants such as total nickel, total copper, total zinc, total chromium, chemical oxygen demand, total phosphorus, and total cyanide that are prone to excessive discharge in electroplating wastewater, Haipu has successfully helped multiple enterprises achieve standard treatment of wastewater with its independently developed series of high-performance adsorbent products as the core, combined with self-developed process technology.

1. Deep nickel removal treatment project for electroplating enterprises

A electroplating enterprise mainly undertakes electroplating processing services in the fields of automobiles, aviation, aerospace, nuclear power, etc. However, the nickel content in the terminal effluent of a set of 120 t/h wastewater treatment facilities of the enterprise has not reached a stable standard.

Our company uses nano adsorbent materials to deeply remove nickel from the wastewater. The nickel content in the effluent is less than 0.05 mg/L, far below the discharge requirement of the enterprise (0.1 mg/L). This solves the problem of excessive nickel in the wastewater of the enterprise and is conducive to the sustainable development of the enterprise.

| Inlet Concentration | Outlet Concentration | Removal Rate |

| ~2mg/L | 0.048mg/L | 97.60% |

| ~2mg/L | 0.039mg/L | 98.05% |

| ~2mg/L | 0.045mg/L | 97.75% |

2. Deep chromium removal treatment project for electroplating enterprises

A electroplating processing enterprise serving the electronics and communication industries generates 200t/d of chromium containing wastewater every day. Our company's designed process treats this wastewater and deeply removes chromium from the wastewater. The chromium removal rate remains stable at over 90%, and the chromium content in the effluent is very low, far below the requirements and discharge standards of the enterprise.

| Raw Water Chromium Content | Treated Water Chromium Content | Removal Rate |

| 5.7mg/L | 0.275mg/L | 95.20% |

| 5.7mg/L | 0.306mg/L | 94.60% |

| 5.7mg/L | 0.279mg/L | 95.10% |

3. Zinc containing wastewater treatment project for electroplating enterprises

The electroplating industry park generates 1062 tons of zinc containing wastewater every day, with zinc and nickel ions exceeding the standard. Our company has designed the process for this wastewater, and the adsorbed nickel and zinc in the effluent can meet the discharge standards.

The nickel ions in the effluent can be stabilized below 0.1mg/L, and the zinc ions can be stabilized below 1mg/L, solving the problem of wastewater treatment in the park.

| Raw Water Zinc Content | Treated Water Zinc Content | Removal Rate |

| 41mg/L | <1mg/L | >97.6% |

| Raw Water Nickel Content | Treated Water Nickel Content | Removal Rate |

| 0.4mg/L | <0.1mg/L | >75% |

4. Nickel containing wastewater treatment project for anodizing in electroplating enterprises

The electroplating industry park generates 2400 tons of anodizing wastewater per day, of which nickel ions exceed the standard. Our company has designed a process for this wastewater to deeply remove nickel elements from the wastewater. The adsorbed nickel in the effluent can be stabilized below 0.1mg/L, meeting the discharge requirements. It can directly enter the middle water tank in the factory area for further treatment.

| Inlet Nickel Content | Outlet Nickel Content | Removal Rate |

| 16mg/L | <0.1mg/L | >99.4% |

5. Cyanide copper wastewater treatment project in electroplating industry park

A electroplating industrial park generates 1125t of cyanide copper wastewater every day, with copper and nickel ions exceeding the standard. Our company has designed a process for this wastewater and implemented comprehensive treatment through multiple stages. The nickel adsorbed water at the end can be stabilized below 0.1mg/L, and the copper ions can be stabilized below 0.3mg/L, meeting the requirements of the enterprise. The effluent can directly enter the middle water tank of the factory area for further treatment.

| Raw Water Copper Content | Treated Water Copper Content | Removal Rate |

| 95mg/L | <0.3mg/L | >99.7% |

| Raw Water Nickel Content | Treated Water Nickel Content | Removal Rate |

| 10mg/L | <0.1mg/L | >99.4% |

6. Phosphorus containing wastewater treatment project for electroplating enterprises

A electroplating enterprise engaged in metal surface treatment and heat treatment processes generates 200 tons of phosphorus containing wastewater per day. Our company has designed a process for this phosphorus containing wastewater to deeply remove phosphorus elements from the wastewater. The total phosphorus content of the adsorbed water can be stabilized below 1mg/L, meeting the requirements of the enterprise. The adsorbed water can be directly discharged, solving the problem of wastewater treatment in the enterprise.

| Raw Water Total Phosphorus Content | Treated Water Total Phosphorus Content | Removal Rate |

| 17mg/L | <1mg/L | >94.12% |

7. Electroplating enterprise passivation solution iron removal resource utilization project

A electroplating processing enterprise serving the electronics and communication industries generates 1000 tons of passivation solution wastewater per day, which contains a large amount of iron, chromium, zinc, etc.

By using our company's nano adsorbent material, the electroplating solution was subjected to deep iron removal treatment. The iron content in the effluent can be reduced to below 0.5mg/L, and some zinc can be removed. The treated passivation solution can be reused in production, greatly increasing the economic benefits of the enterprise.

| Inlet Water Iron Content | Outlet Water Iron Content | Removal Rate |

| 520mg/L | 0.39mg/L | 99.93% |

| 520mg/L | 0.19mg/L | 99.96% |

| 520mg/L | 0.26mg/L | 99.95% |

Haipu Cooperative Electroplating Enterprise Wastewater Treatment Project Exhibition

CN

CN