1. Current situation of ammonia nitrogen wastewater treatment

Ammonia nitrogen wastewater mainly comes from industries such as fertilizers, coking, petrochemicals, pharmaceuticals, and food. Treatment methods for ammonia nitrogen wastewater usually include physical, chemical, physicochemical, and biochemical methods.

(1) Biological method for treating ammonia nitrogen wastewater

The traditional biochemical method is mainly used for the treatment of low concentration ammonia nitrogen wastewater, which utilizes the nitrification and denitrification of microorganisms to convert ammonia nitrogen into nitrogen gas. Low concentration ammonia nitrogen wastewater usually has the characteristic of low concentration, and some production wastewater even does not contain COD. Therefore, biological denitrification is used for treatment, which requires the addition of carbon sources and has high operating costs. Common processes include A/O or A2/O and SBR processes. Its disadvantage is that the treatment process is very sensitive to temperature and interference from certain components in industrial wastewater, requiring a relatively large reactor volume. In addition, during denitrification, N 2 O is produced, which is easily converted into other nitrogen oxides that affect the ozone layer. Denitrification converts valuable substances such as NH 4+into N 2 and escapes into the air, resulting in waste. In the A/O process, in order to promote the smooth progress of denitrification reaction, it is generally required that the C/N ratio be greater than 3.

(2) Steam stripping method for ammonia nitrogen wastewater treatment

The steam stripping method is a process that uses steam to convert free ammonia in wastewater into ammonia gas and release it. Its treatment mechanism is basically the same as the blow off method, and it is also a gas-liquid mass transfer process. That is, at high pH values, the wastewater is in close contact with steam, thereby reducing the concentration of ammonia in the wastewater. The driving force of mass transfer process is the difference between the partial pressure of ammonia in the gas phase and the equilibrium partial pressure corresponding to the concentration of ammonia in the wastewater. The steam stripping method uses steam as the working medium, and ammonia enters the steam from wastewater and is then distilled at the top of the tower to become concentrated ammonia water for recovery, so there is no need to add a post-treatment process. The steam volume required for steam stripping is much smaller than the air volume required in air stripping method, so the equipment has a smaller volume and occupies less space. The stripping method is more suitable for treating high concentration ammonia nitrogen wastewater above 1000mg/L, with a removal rate of over 99% for ammonia nitrogen, high efficiency, and good technological maturity. However, conventional steam stripping wastewater deamination technology consumes a large amount of steam and has a relatively high unit consumption for treating wastewater. The popularization, promotion, and application of steam stripping wastewater deamination technology require increased research and development efforts in energy conservation and consumption reduction.

(3) Ion exchange method for ammonia nitrogen wastewater treatment

The ion exchange method is suitable for wastewater with an ammonia ion concentration of 10-100mg/L. The principle is to use cation exchange resin to exchange ammonium ions in water with sodium ions on the resin, thereby achieving the goal of removing ammonium. Zeolite has the characteristic of selectively removing ammonia ions from solutions containing sodium, magnesium, and calcium ions. Therefore, choosing it as an exchange resin is also called selective ion exchange method. The penetrating resin needs to be regenerated with a 2% sodium chloride solution, and the regenerated solution is recycled after ammonia treatment to a certain circulation rate before being discharged. The regeneration operation of ion exchange ammonia removal resin is complex, and the equipment and pipelines are severely corroded. The regenerated ammonia has low value for reuse, so industrial scale applications are rare.

(4) Chemical precipitation method

The chemical precipitation method is to add chemical agents to water to cause ammonia to react and form insoluble precipitates, thereby achieving the goal of ammonia removal from wastewater. The commonly used chemical agents are magnesium salts and soluble phosphates. The removal rate of ammonia nitrogen by chemical precipitation method is generally 80% -90%. The process is relatively simple and the equipment investment is relatively low. However, due to the need to add phosphate that is strictly controlled by the state for discharge into wastewater (the national first level standard requires phosphorus<0.5mg/L), the subsequent phosphorus removal requirements are very high. Therefore, this process is generally only suitable for situations where ammonia nitrogen and phosphorus coexist.

(5) Membrane Separation Method for Ammonia Nitrogen Wastewater Treatment

The use of membrane separation technology to treat ammonia nitrogen wastewater is one of the most extensively studied wastewater deamination technologies in recent years. The membrane separation technology has a good treatment effect on ammonia nitrogen wastewater with mild conditions. Due to the high concentration of suspended solids and salts that are prone to scaling in ammonia nitrogen wastewater, membrane separation technology requires high water quality considering membrane blockage and regeneration issues.

(6) Reverse osmosis and electrodialysis methods

The investment and operating costs of reverse osmosis and electrodialysis are relatively high. Moreover, the pre-treatment requirements of electrodialysis are high, and the service life of reverse osmosis membranes is short, so their application in China is currently very rare. Generally, biochemical treatment is used to reduce the ammonia nitrogen content in wastewater. With the rapid development and growth of industries such as fertilizers and petrochemicals, more and more high ammonia nitrogen wastewater cannot meet the biochemical treatment standards, which has become an important factor restricting the development of the industry.

2. Haipu customized ammonia nitrogen wastewater treatment process

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has achieved international leading levels in ion exchange technology and adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

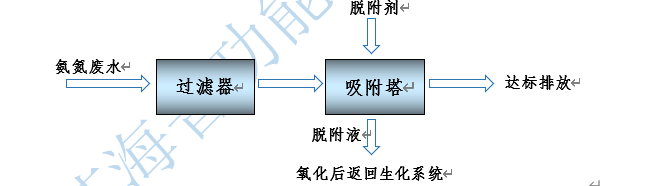

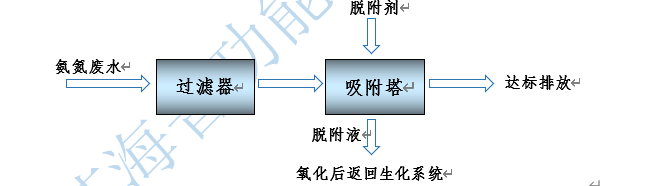

Figure 1 Ammonia nitrogen water treatment process

The special adsorption material researched by Haipu Company can selectively adsorb ammonia nitrogen substances in wastewater, achieve efficient adsorption and complete desorption of ammonia nitrogen substances, and the ammonia nitrogen content in the desorbed wastewater can meet the discharge standards. When using Haipu's adsorption process to treat ammonia nitrogen wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb ammonia nitrogen in the wastewater on the surface of the material, and the effluent ammonia nitrogen can meet the discharge standards. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The process flow of ammonia nitrogen wastewater adsorption treatment is shown in the following figure.

3. Case Introduction of Ammonia Nitrogen Wastewater Treatment

This newly built ammonia nitrogen wastewater adsorption treatment facility has a total designed wastewater treatment capacity of 300m3/d. The ammonia nitrogen content in the ammonia nitrogen wastewater is high, and the ammonia nitrogen content after biochemical treatment exceeds the discharge standard, which affects the stable production of the enterprise. Haipu has customized the process design for the wastewater, and the wastewater design indicators are shown in the table below.

Case 1 Adsorption of inlet and outlet water data

| Water volume (m³/d) | Ammonia nitrogen concentration in raw water (mg/L) | Ammonia nitrogen concentration in effluent (mg/L) | Removal rate |

| 300 | 300 | 12.3 | 96% |

The adsorption process customized by Haipu can deeply adsorb and remove ammonia nitrogen from wastewater, with a stable removal rate of over 90%. The ammonia nitrogen content in the adsorbed water is much lower than the customer's requirements (<25mg/L). As can be seen from the figure, most of the ammonia nitrogen in the wastewater is adsorbed and removed, and at least a certain amount of ammonia nitrogen is transferred to the desorption solution. After oxidation, the desorption solution can be directly returned to the front-end biochemical system, meeting the customer's discharge requirements without generating secondary pollution, ensuring the normal operation of the enterprise.

4. Advantages of adsorption method

Efficiently remove ammonia nitrogen substances from wastewater with high removal efficiency, and strictly control the ammonia nitrogen content in the effluent (effluent ammonia nitrogen content<15mg/L);

Deep treatment of biochemical wastewater with high concentration ratio, solving the problem of low concentration wastewater treatment;

Low design investment, low operating costs, advanced technology, and no secondary pollution;

The process flow is simple, reliable, and occupies a small area.

CN

CN