Nickel is widely used in surface treatment technology and is also commonly used in coloring and sealing in oxidation workshops.

Now facing environmental pressure, the pre-treatment of wastewater requires a concentration of 0.1mg/L, and many factories have abandoned the use of nickel containing chemicals.

However, using nickel free products is not only expensive, but also able to achieve qualified chemical properties with nickel free chemicals, and the difficulty is not lower than that of treating nickel containing wastewater.

Difficulty in treating nickel containing wastewater

Why is it difficult to meet the standard for pre-treatment of nickel containing wastewater? In order to ensure the stability and service life of the tank solution, in addition to adding a large amount of soluble nickel salts, a large amount of chelating agents, surfactants, stabilizers, brighteners, and pH buffering agents need to be added to the tank solution.

The chelating agents used in the oxidation workshop are mostly organic acids, such as citric acid, tartaric acid, amino sulfonic acid, hydroxyacetic acid, phenols, and acetic acid.

The chelating agent contains multiple ligands that bind to nickel ions, hindering the precipitation of nickel hydroxide. Therefore, only by destroying these chelating agents can a good chemical precipitation effect be achieved.

Adding different chelating agents to various brands of additives can form different types of coordination ions, so the difficulty of treating nickel containing wastewater varies depending on the type of chelating agent added.

At present, chemical precipitation method is mainly used to treat nickel plating wastewater, such as adjusting pH, using lime as precipitant, and prolonging reaction time to treat nickel containing wastewater, but the effect is not very good.

Other processing methods include ion exchange resin method, electrodialysis method, membrane separation method, and solvent extraction method.

Due to the complex composition of nickel containing wastewater, the cost-effectiveness of existing methods is not high, and other problems may arise.

The ordinary chemical precipitation method has poor treatment efficiency; Ion exchange method has limited resin processing capacity and is prone to oxidation and contamination; The selectivity and durability of electrodialysis are poor, and the permeable membrane is prone to fouling.

The operation and maintenance costs of membrane separation technology are high; The solvent extraction method is still being further studied and explored as an effective extractant for widely used acidic waste liquids.

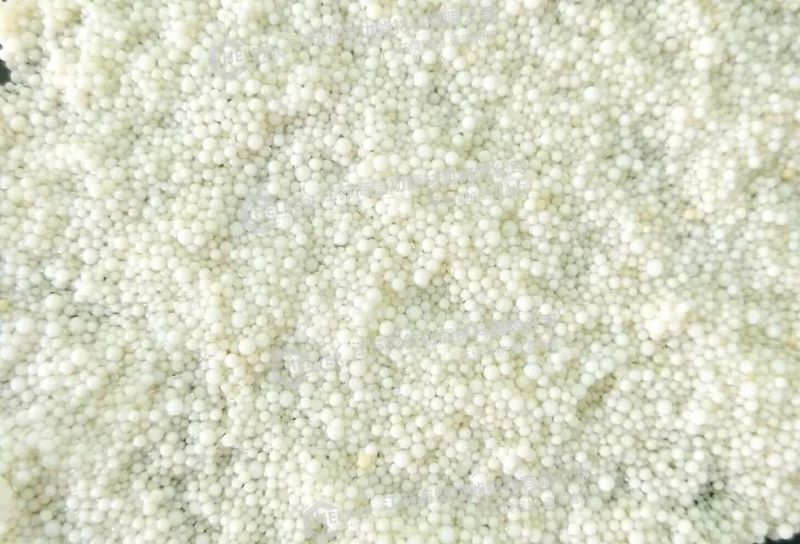

HPF606/HP4020/HP8

Nickel adsorbent

To meet the needs of enterprises for efficient, easy to operate, stable and highly automated treatment of nickel containing wastewater.

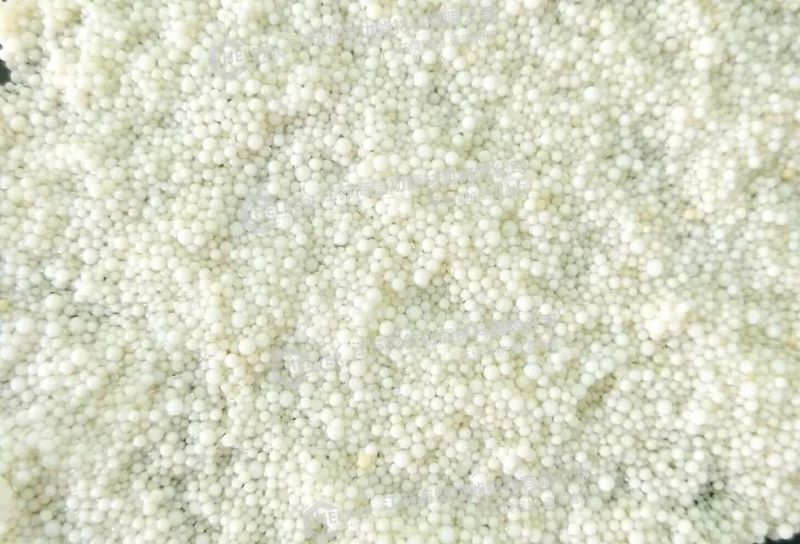

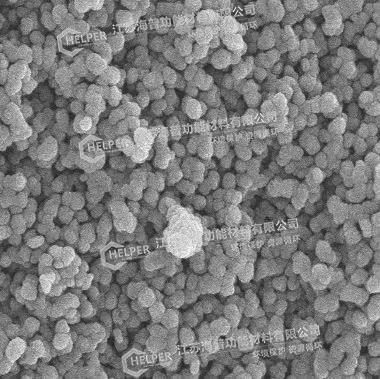

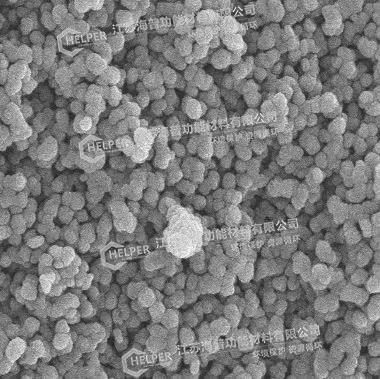

The research team of Haipu Functional Materials has developed an adsorbent product based on the characteristics of typical industry wastewater quality and treatment processes - nano hybrid nickel removal adsorbent.

Haipu nickel removal adsorbent is suitable for nickel containing heavy metal wastewater, efficiently removing nickel from wastewater with high removal rate. It strictly controls the nickel ion content in the effluent and solves the problem of nickel containing wastewater treatment.

There are three types of fluoride removal adsorbent product models according to different application scenarios

HPF606 HPF4020 HP8

Can be used for adsorption recovery and standard treatment of nickel ions in electroplating industry, wet metallurgy, waste batteries, and catalyst wastewater.

What are the differences between our nickel removal adsorbents

Compared with other nickel removal technologies, Haipu nano hybrid nickel removal adsorbent has significant application advantages in terms of operating cost and efficiency.

The material can selectively remove nickel from wastewater, achieve efficient adsorption of nickel ions, and the nickel ion content in the adsorbed wastewater is low, which can meet the discharge standards.

After adsorption saturation, desorption treatment is carried out using a desorption agent, and the desorbed adsorbent can be regenerated and reused for adsorption.

The process of using this product can be applied to various heavy metal wastewater with high removal rate, and can also deeply treat low concentration nickel containing wastewater with high concentration ratio, solving the problem of low concentration nickel containing wastewater treatment.

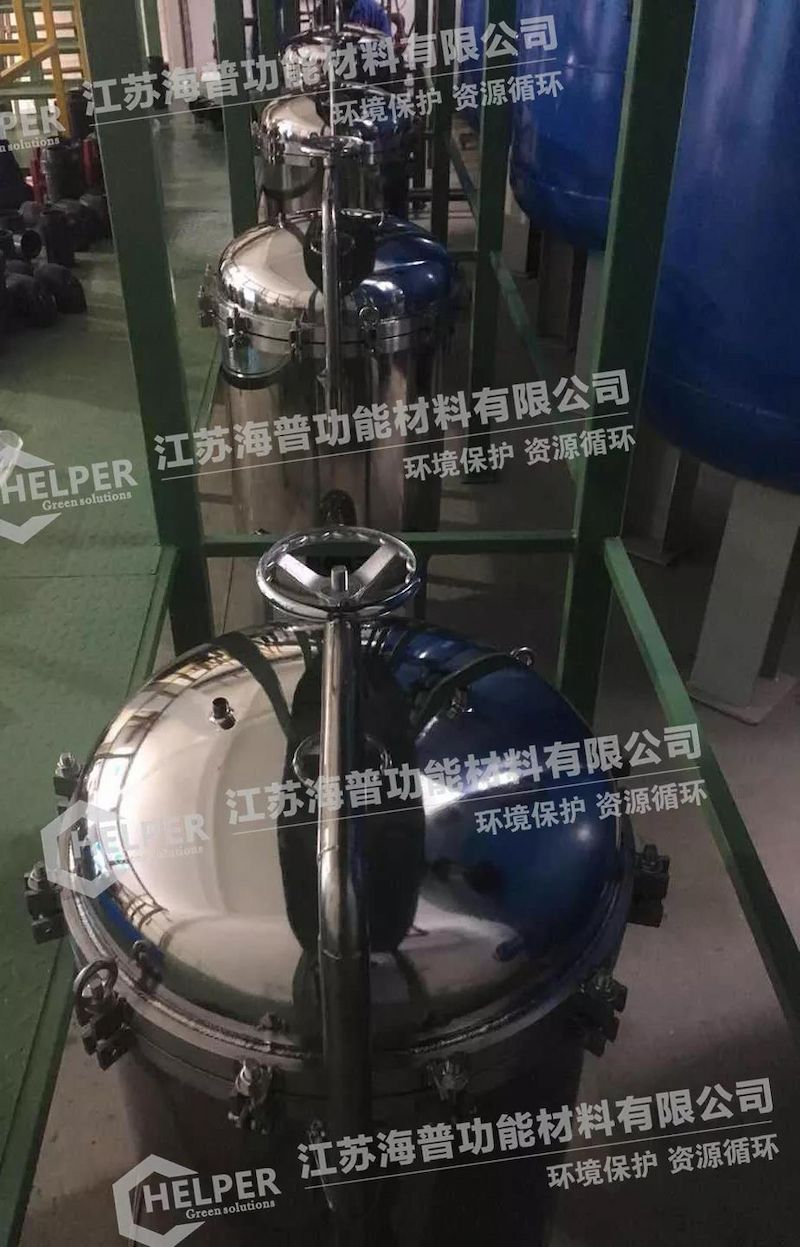

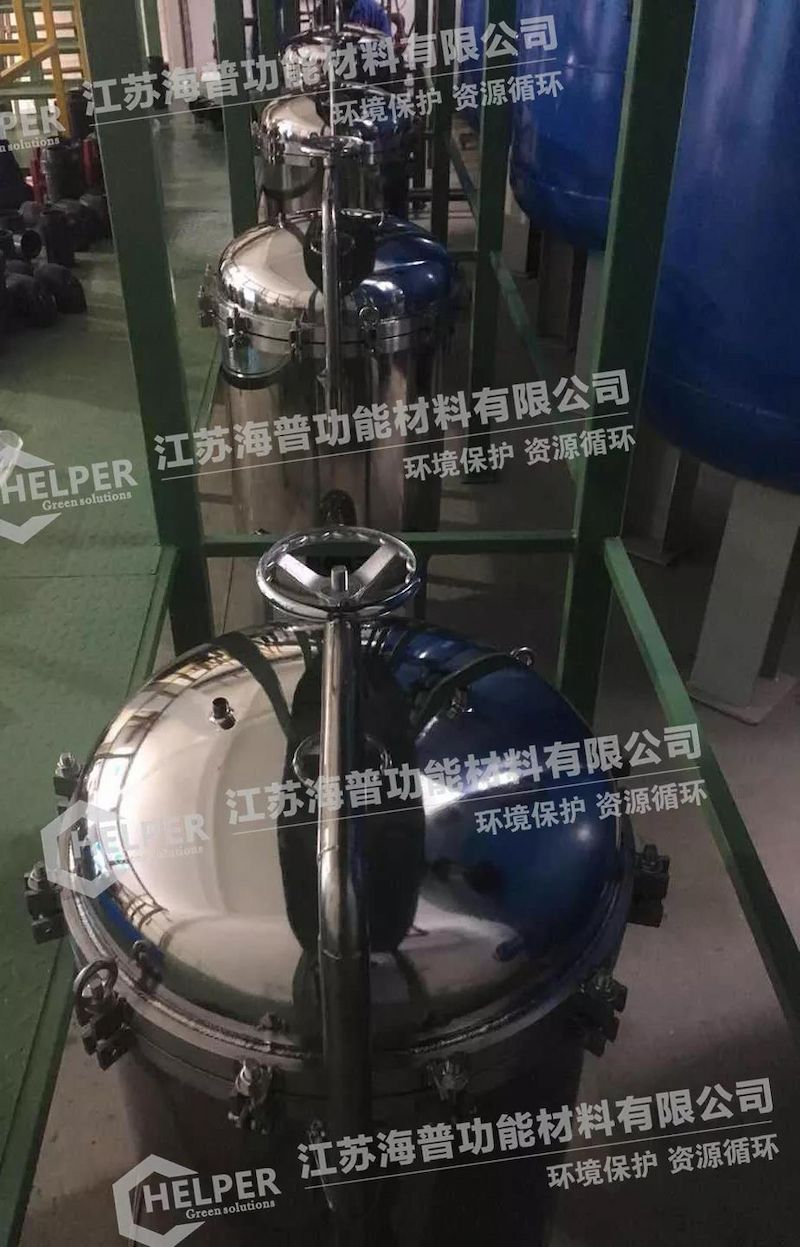

Moreover, it adopts a modular component form, with a high degree of automation and simple operation.

Product application effect

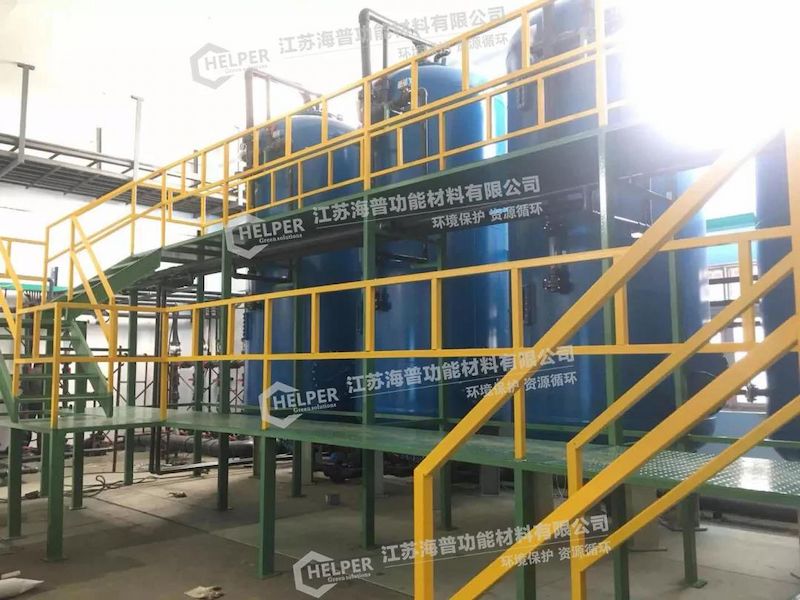

Based on practical and feasible nano hybrid nickel removal adsorbent products and their supporting combination processes, Haipu has helped multiple customers meet the treatment needs of nickel containing wastewater.

Application Case 1 of Nano Hybrid Nickel Removal Adsorbent

A certain electroplating enterprise mainly undertakes electroplating processing services in the fields of automobiles, aviation, aerospace, nuclear power, etc. The nickel content in the terminal effluent of a set of 120t/h wastewater treatment facilities of the enterprise has not reached a stable standard.

Using Haipu nickel removal adsorbent, the wastewater was subjected to deep nickel removal treatment. The nickel content in the effluent was less than 0.05mg/L, far below the discharge requirement of the enterprise (0.1mg/L). Solving the problem of excessive nickel in the enterprise wastewater is beneficial for the sustainable development of the enterprise.

| Influent concentration | Effluent concentration | Removal rate |

| ~2mg/L | 0.048mg/L | 97.60% |

| ~2mg/L | 0.039mg/L | 98.05% |

| ~2mg/L | 0.045mg/L | 97.75% |

Application case of nano hybrid nickel removal adsorbent 2

A certain electroplating industry park generates 2400 tons of anodizing wastewater every day, of which nickel ions exceed the standard.

Using Haipu nickel removal adsorbent and supporting facilities for process treatment of the wastewater, the nickel element in the wastewater is deeply removed, and the adsorbed water nickel can be stabilized below 0.1mg/L, meeting the discharge requirements. It can directly enter the middle water tank of the plant area for further treatment.

| Inlet nickel content | Nickel content in effluent | Removal rate |

| 16mg/L | <0.1mg/L | >99.4% |

Application Cases of Nano Hybrid Nickel Removal Adsorbents 3

The nickel containing wastewater generated during the production process of an enterprise has a nickel ion concentration of 1.462mg/L. The enterprise requires that the nickel content be reduced to 0.1mg/L after treatment, which belongs to deep nickel removal and has relatively high requirements for the process.

The treatment experiment was conducted using Haipu nickel removal adsorbent and supporting technology. The experimental results showed that the removal rate of nickel ions by adsorption was as high as 95%. The adsorbed water nickel ions could meet the discharge standards and the requirements of the enterprise, reducing the pressure for the subsequent treatment of enterprise wastewater and ensuring the normal production of the enterprise.

| Nickel content in raw water | Nickel content in effluent | Removal rate |

| 1.462mg/L | 0.067mg/L | 95.40% |

| 1.462mg/L | 0.084mg/L | 94.30% |

| 1.462mg/L | 0.072mg/L | 95.10% |

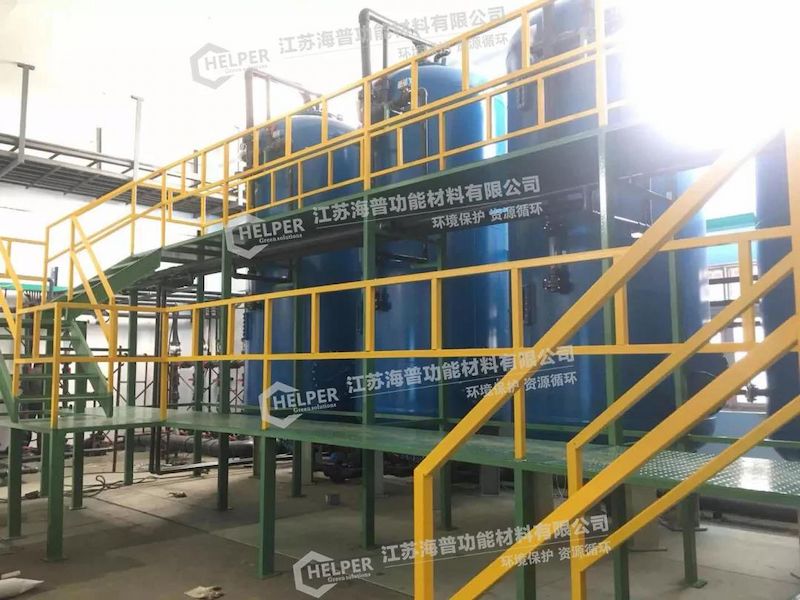

Practical case demonstration of nickel adsorbent application

CN

CN