Fluorine is a non-metallic chemical element with the chemical symbol F, and is the most non-metallic element among known elements.

Fluorine is mainly distributed in the bones and teeth of the human body, where about 90% of fluorine is accumulated. The blood contains 0.04 to 0.4 micrograms per milliliter.

Fluoride, as an essential trace element in the human body, can not only prevent dental caries but also promote bone metabolism.

However, at the same time, fluorine is also an important source of pollution in the ecological environment that cannot be ignored.

Long term excessive intake of fluoride can lead to dental fluorosis. In addition, due to the bone friendly properties of fluoride, it can also alter the body's bone density, and in severe cases, lead to fluorosis.

On October 27, 2017, fluoride was included in the list of carcinogens released by the International Agency for Research on Cancer of the World Health Organization.

Current situation of fluoride removal

In industry, wastewater discharged from industries such as fluorine-containing ore mining, metal smelting, aluminum processing, coking, glass, electronics, electroplating, fertilizers, pesticides, etc. often contains high concentrations of fluoride.

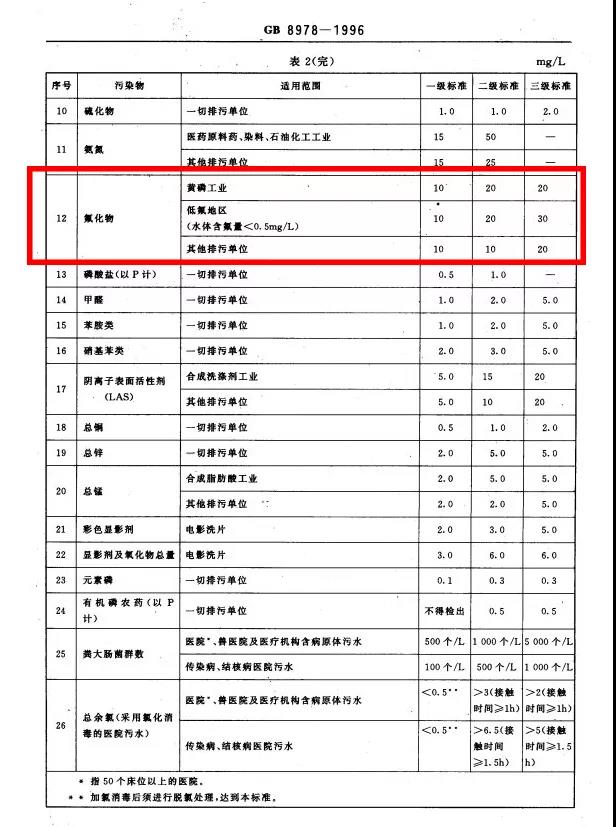

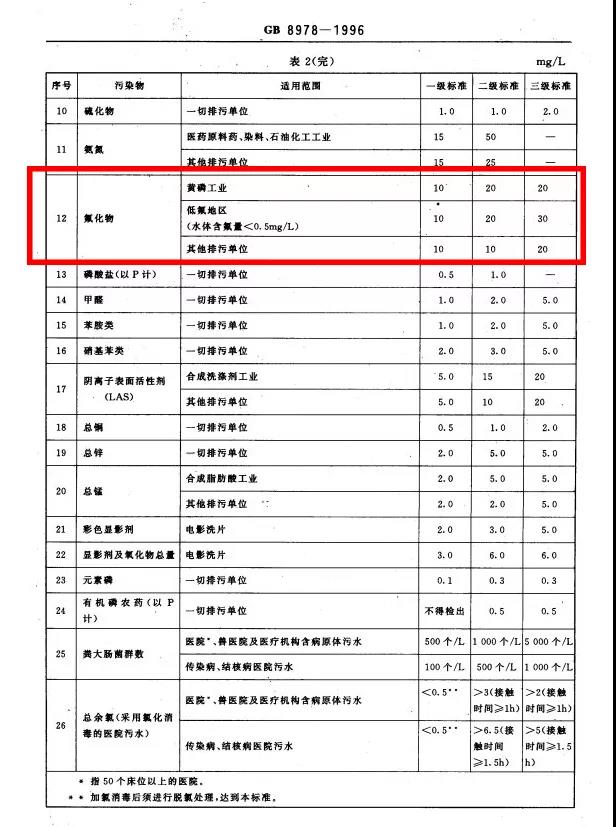

So, the country has also introduced strict institutional standards for monitoring and discharging fluorine-containing wastewater.

At present, there are several widely used defluorination technologies in the corresponding market fields, including:

Fluoride Removal Application Technology

| Method | Advantage | Shortcoming |

| Precipitation method | Simple process, suitable for the treatment of high concentration fluorine-containing wastewater | High investment volume, difficult to meet standards; Large mud production and difficult dehydration |

| Ion exchange method | Simple operation and management, suitable for low to medium concentration fluoride water treatment | High cost of ion exchange resin and high cost of regeneration |

| Electrodialysis method | Simple preprocessing, suitable for small-scale defluorination systems | High infrastructure and operating costs, high requirements for operation and maintenance personnel |

| Nanofiltration/reverse osmosis method | Ro has a very high fluoride removal rate and is not affected by coexisting ions | High investment and operating costs; There is a problem with concentrated water treatment, and the operation is complex |

HPF2000HPF4000HPF5200

Defluorination adsorbent

To meet the needs of enterprises for efficient, simple, and low-cost treatment of fluorine-containing wastewater.

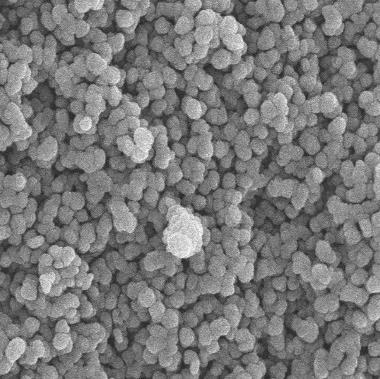

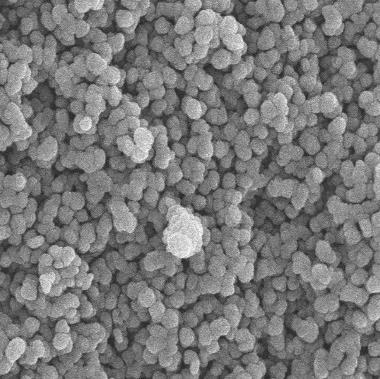

The research team of Haipu Functional Materials has developed a nanohybrid fluoride removal adsorbent product based on the characteristics of typical industry wastewater quality and treatment processes.

Haipu defluorination adsorbent has high selectivity for defluorination, strong anti-interference ion resistance, stable performance, and can be used repeatedly for a long time.

There are three types of fluoride removal adsorbent product models according to different application scenarios.

HPF2000HPF4000HPF5200

Can be applied to remove fluoride from fluorine-containing materials in the recycling of waste batteries, treat various fluorine-containing wastewater to meet standards, and remove fluoride from drinking water.

What are the differences between our defluorination adsorbents.

Compared with other defluorination technologies, Haipu nanohybrid defluorination adsorbent has significant application advantages in terms of operating cost, operating efficiency, safety, and avoiding secondary pollution.

After pre-treatment, the raw water is filtered and connected to an adsorption tank. The fluoride ions in the water are adsorbed and enriched in an adsorption tower equipped with a nanohybrid fluoride removal adsorbent, and the effluent can meet the design specifications.

After adsorption saturation, desorption treatment is carried out using a desorption agent, and the desorbed adsorbent can be regenerated and reused for adsorption.

The process of using this product can be applied to the treatment of drinking water, industrial wastewater, and industrial waste liquid with different fluoride concentrations and project scales.

Product application effect

Based on practical and feasible nano hybrid fluoride removal adsorbent products and their supporting combination processes, Haipu has helped multiple customers meet the treatment needs of fluorine-containing wastewater.

Application Case 1 of Nano Hybrid Fluoride Removal Adsorbent

A mining enterprise produces groundwater with a fluoride content of about 1.4mg/L during the process of mining ore. The enterprise requires that the fluoride content in the treated wastewater be less than 0.5mg/L.

The experimental treatment effect shows that using Haipu nano hybrid fluoride removal adsorbent products for treatment, the fluoride ion removal rate in wastewater remains stable at over 92%, and the fluoride content in effluent can be controlled below 0.5mg/L.

Keeping a certain safety margin while ensuring compliance with customer requirements can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 1.4mg/L | 0.04mg/L | 97.14% |

| 1.4mg/L | 0.10mg/L | 92.86% |

| 1.4mg/L | 0.08mg/L | 94.28%

|

Application Cases of Nano Hybrid Fluoride Removal Adsorbents 2

A company produces wastewater with a fluoride content of about 300mg/L, and requires the fluoride content in the treated wastewater to be less than 10.0mg/L.

The experiment used Haipu nano hybrid fluoride removal adsorbent products for treatment, and the fluoride ion removal rate in the wastewater remained stable at over 96%. The fluoride content in the effluent was less than 10.0mg/L.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 300mg/L | 9.1mg/L | 96.97% |

| 300mg/L | 9.5mg/L | 96.83% |

| 300mg/L | 9.4mg/L | 96.87% |

Application Cases of Nano Hybrid Fluoride Removal Adsorbents 3

A company produces 100 tons/day of wastewater with a pH of 9.5 and a fluoride content of 10.5mg/L during the production process, with a treatment requirement of ≤ 1mg/L.

For this purpose, our company uses nano hybrid fluoride removal adsorbent products to adsorb and separate fluoride ions in drinking water. The fluoride content after adsorption treatment is significantly reduced, which meets the customer's treatment requirements for this indicator.

| Fluorine content in raw water | Fluorine content in effluent | Removal rate |

| 10.5mg/L | 0.29mg/L | 97.24% |

| 10.5mg/L | 0.17mg/L | 98.38% |

| 10.5mg/L | 0.15mg/L | 98.57% |

| 10.5mg/L | 0.11mg/L | 98.95% |

CN

CN