Wastewater discharged from printing and dyeing, woolen dyeing and finishing, and silk factories mainly processing cotton, hemp, chemical fibers and their blended products, and silk. The amount and quality of printing and dyeing wastewater vary depending on the type of fiber and processing technology. Among them, the amount of wastewater from printing and dyeing factories is relatively large, with 100-200 tons of water consumed for every 1 ton of textile processed, of which 80% -90% is discharged as wastewater. Printing and dyeing wastewater has the characteristics of large water volume, high organic pollutant content, high alkalinity, and large water quality changes. It is one of the difficult industrial wastewater to treat. The wastewater contains dyes, pulp, additives, oil agents, acid and alkali, fiber impurities, sand substances, inorganic salts, etc. The policy stipulates that the wastewater reuse rate in the printing and dyeing industry must reach 60%. The existing wastewater treatment process in the textile industry has excessive COD in the biochemical effluent, which cannot meet the reuse standards. Currently, most of the production wastewater from enterprises is sent to sewage treatment plants for further treatment.

According to the production needs of the enterprise, our company has designed the process for the reuse of printing and dyeing wastewater and reclaimed water. We have adopted our adsorption technology to treat this wastewater, which can meet the requirements of reuse. While solving the problem of wastewater treatment in the enterprise, we have reduced the cost of outsourcing wastewater treatment and adding new water, which has significant economic benefits. Based on this, we have issued this technical solution for the reference of the enterprise.

Below, Jiangsu Haipu Functional Materials will provide a detailed introduction to the characteristics and treatment methods of reclaimed water reuse, hoping to be helpful to you.

Current situation and challenges in the treatment of printing and dyeing wastewater:

In the production of the chemical industry, different types of wastewater are generated, among which organic wastewater is more common. This type of wastewater contains a large amount of organic pollutants, which are highly toxic, concentrated, have a high chemical oxygen demand, and poor biodegradability. It also contains a large amount of salt and acidic substances, which are extremely harmful to water bodies and human health. Once organic wastewater is discharged into clean water bodies in nature, it will cause eutrophication of water quality, leading to water odor, color deepening, and serious deterioration. Therefore, it is necessary to carry out treatment. Below, Haipu will provide you with detailed information on organic wastewater treatment solutions, hoping to be helpful to you.

The main characteristics of organic wastewater are as follows:

The composition of chemical wastewater is complex, and the reaction raw materials are often solvent based substances or cyclic compounds, which increases the difficulty of wastewater treatment.

The wastewater contains a large amount of pollutants, mainly due to incomplete reaction of raw materials or the use of a large amount of solvents in production.

There are many toxic and harmful substances, and there are many organic pollutants in fine chemical wastewater that are toxic and harmful to microorganisms, such as halogen compounds, nitro compounds, dispersants or surfactants with bactericidal effects, etc.

There are many biologically recalcitrant substances, low BOD/COD, and poor biodegradability.

Since the 13th Five Year Plan, the country has attached increasing importance to ecological environment protection, and the standards for wastewater discharge and the total control of regional wastewater discharge have become increasingly strict. The 13th Five Year Plan clearly states that by 2020, the total emissions of chemical oxygen demand, ammonia nitrogen, sulfur dioxide, and nitrogen oxides in China will be controlled within 20.01 million tons, 2.07 million tons, 15.8 million tons, and 15.74 million tons, respectively. Since 2015, multiple emission standards have been implemented in the chemical industry. The policy stipulates that newly established enterprises will officially implement them from July 1, 2015, while existing enterprises will implement them from July 1, 2017. Therefore, after the second half of 2017, the pollution discharge standards of existing chemical industrial parks will be stricter.

Table 1-1 Upgrading of Main Indicators for Emission Standards in Chemical Industrial Parks

| Name | SS(mg/L) | Ammonia nitrogen (mg/L) | COD(mg/L) | BOD(mg/L) | Petroleum (mg/L) |

| Emission Standards for Pollutants from Inorganic Chemical Industry GB31573-2015 | 50 | 10 | 50 | / | 3 |

| Pollutant Emission Standard for Synthetic Resin Industry GB31572-2015 | 30 | 8 | 60 | 20 | / |

| Emission Standards for Pollutants from Petrochemical Industry GB31571-2015 | 70 | 8 | 60 | 20 | 5 |

| Emission Standards for Pollutants from Petroleum Refining Industry GB31570-2015 | 70 | 8 | 60 | 20 | 5 |

Due to the complex elemental composition of organic wastewater, the treatment methods adopted in China mainly include incineration, adsorption, Fenton oxidation, biological method, iron carbon microelectrolysis method, and photocatalytic oxidation method. This article compares and summarizes these organic wastewater treatment technologies (see Table 2-1).

| Organic wastewater treatment process | Advantage | Shortcoming |

| Incineration method | The process flow is simple and suitable for various types of organic wastewater enterprises for easy operation and management | 1. Incineration of flue gas requires further treatment to meet emission standards

2. The incineration cost is high, generally charged at 1000 yuan/ton

3. With the increasing environmental requirements, the cost of incinerating wastewater is likely to continue to rise |

| Adsorption method | 1. Continuous, efficient, and stable deep treatment of organic matter, capable of meeting stricter emission limits (COD<30mg/L, ammonia nitrogen<5mg/L)

2. Efficiently remove recalcitrant organic compounds from wastewater, improve the BOD/COD of wastewater, and ensure that the enterprise can carry out biochemical treatment in the future

3. Nano adsorbent materials have a large adsorption capacity, renewable use, and long service life

4. Modular component form, occupying less space, compact structure, high degree of automation, and simple operation | Organic wastewater has complex components, and adsorption materials exhibit different adsorption abilities for different substances. One adsorption material can specifically adsorb one substance. |

| Fenton oxidation method | The Fenton oxidation method does not require high temperature and pressure, has fast speed, mild reaction conditions, simple equipment, and low equipment investment | 1. When dealing with high concentration pollutants, the consumption of H2O2 is high, resulting in higher wastewater treatment costs

2. If the applicable pH range is small, it should be carried out under conditions where the pH is below 3, and the treated water still exhibits strong acidity

3. Equipment materials are prone to failure and compaction, and will produce a large amount of iron mud, making subsequent treatment complex and increasing the cost of wastewater treatment

This one

4. Some difficult to degrade organic compounds such as pyridine cannot be completely oxidized, resulting in low treatment efficiency. |

| Biological Law | The biological process is simple and has low operating costs, making it one of the most widely used and effective wastewater treatment methods for organic wastewater | 1. Biological methods have high requirements for the concentration and composition of wastewater, and are not resistant to high impact loads

2. Bacteria using biological methods have low tolerance for some difficult to degrade and toxic organic compounds, and may even be unable to process them at all

3. Biological methods require multiple reaction tanks, occupy a large area, and have high management and operational requirements. |

| Iron carbon microelectrolysis method | Effectively removing the chromaticity and suspended solids of mixed wastewater, the various indicators of the wastewater have been greatly improved after comprehensive treatment, reducing the cost and load of subsequent treatment | 1. For some difficult to degrade organic compounds such as pyridine, they cannot be completely oxidized, resulting in low treatment efficiency

2. Fillers are prone to agglomeration and purification, resulting in waste and ineffective fillers. These fillers contain abundant iron and organic pollutants, which cannot be directly discharged and require further treatment

3. Iron powder causes severe wear and tear on equipment, with high material requirements and high maintenance costs

4. The equipment has a high mixing power, high electricity consumption, and consumes a large amount of acid solution for maintenance, resulting in high overall operating costs. |

| Photocatalytic oxidation method | Using inexpensive semiconductor catalysts as materials and solar energy as energy, without the need for chemical reagents, the main operating cost is electricity, and the operating cost is not high, which has potential advantages. | 1. High cost, low catalytic efficiency and stability of catalysts

2. The conduction efficiency of light in high concentration wastewater is low, and sometimes the rate of complete oxidation of organic matter is relatively slow, resulting in low treatment capacity

3. The equipment requirements for enterprises are relatively high, making it difficult to be widely applied to the production process of enterprises

|

Table 2-1 Comparison of Advantages and Disadvantages of Organic Wastewater Treatment Processes

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. Through years of independent research and development, we have achieved international leading levels in ion exchange technology, adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products, and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

The application cases of Haipu nano adsorbent technology are as follows:

Industry customer demand:

The policy stipulates that the wastewater reuse rate in the printing and dyeing industry must reach 60%. The existing wastewater treatment process has exceeded the COD standard for biochemical wastewater, which cannot meet the reuse standard. Currently, the production wastewater of enterprises is sent to the sewage treatment plant for further treatment. According to the production needs of the enterprise, our company has designed a process for 1000t of biochemical wastewater and adopted our adsorption technology to treat the wastewater, which can meet the requirements of reuse. While solving the problem of wastewater treatment in the enterprise, it reduces the cost of outsourcing wastewater treatment and adding new water, and has significant economic benefits. Based on this, this technical solution is issued for the reference of the enterprise.

Introduction to Haipu customized process:

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a company that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to provide customers with solutions a national high-tech enterprise that solves relevant environmental problems. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

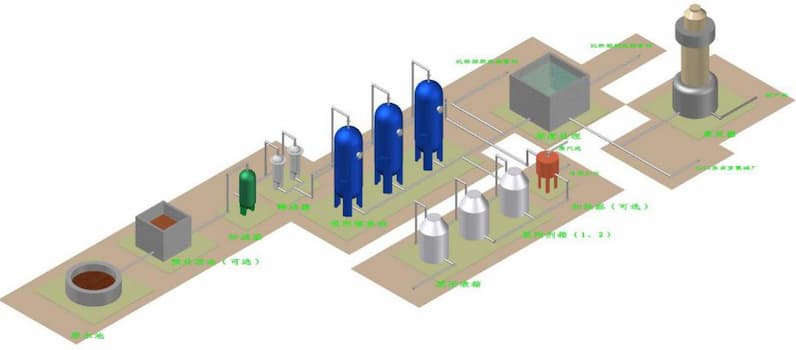

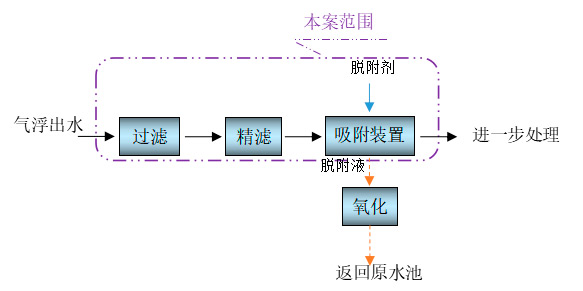

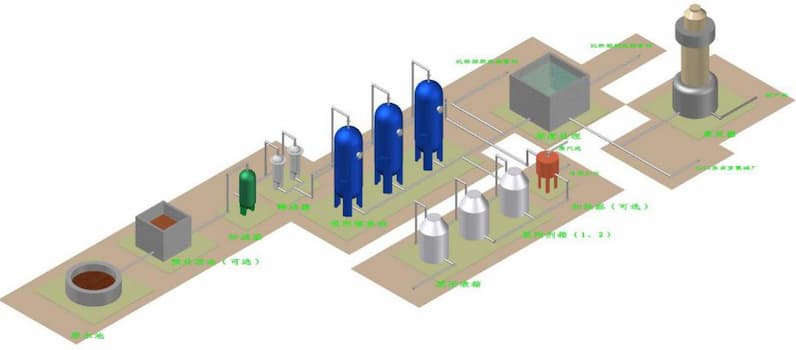

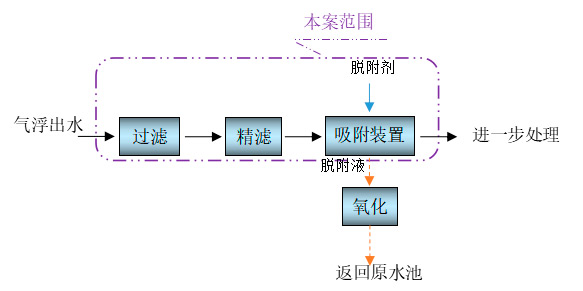

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to be regenerated. This process is continuously repeated. The conventional process of treating wastewater by adsorption method is shown in the following figure.

Conventional process diagram for adsorption treatment of wastewater

When using Haipu's adsorption process to treat COD wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb the organic matter in the wastewater on the surface of the material, ensuring that the effluent continues to meet the discharge standards. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The process flow of COD removal wastewater adsorption treatment is shown in the following figure.

Process flow of COD wastewater adsorption treatment

4. Process treatment effect

The adsorption process is used to treat COD containing wastewater, which can effectively remove COD from the wastewater and achieve the purpose of reclaimed water reuse. The specific treatment data is shown in the table below:

| Project | Raw water COD | Effluent COD | Removal rate |

| (mg/L) | (mg/L) |

| 1 | 164 | 40.5 | 75.30% |

| 2 | 164 | 42.3 | 74.20% |

| 2 | 164 | 41.4 | 74.60% |

Figure Appearance of raw water (left) and treated effluent (right)

From the experimental results, the COD removal rate remained stable at over 70%, and the effluent COD was much lower than the customer's requirement (<50mg/L). The raw water is brown in color, and the effluent is basically colorless and clear. Most of the organic matter in the wastewater has been removed. Experiments have shown that adsorption removal of COD in wastewater is an effective treatment method.

Core advantages of craftsmanship:

At present, the treatment methods for COD wastewater reuse have their own shortcomings in terms of treatment effectiveness and operating costs. The adsorption method can effectively remove COD from wastewater below the reuse standard, making it an economical and effective method for treating COD wastewater. Its advantages include the following points

(1) Stable compliance with emission standards or returning to production lines can effectively alleviate the environmental pressure on enterprises.

(2) Conduct experiments on the sampling samples of wastewater generated on the enterprise site, based on technology, and design adsorption processes based on experiments. The matching degree between wastewater and processes is 100%.

(3) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs.

(4) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install.

(5) Advanced and mature technology, no secondary pollution, strong technical support, and rich engineering application experience.

Case Introduction: A 1000t/d COD containing wastewater water reuse project in a printing and dyeing enterprise in Jiangsu Province:

The company uses our adsorption process to treat the COD containing wastewater generated during its production process. Experiments have shown that the COD content in the wastewater has decreased from the original 164mg/L to below 50mg/L, with a removal rate of 70%. The treated wastewater can be directly reused, reducing the environmental pressure on the enterprise. The COD in the desorption solution is further processed.

On site application of adsorption tower

CN

CN