Keywords: adsorption waste salt recovery

1. Overview of mixed salt wastewater

Mixed salt wastewater refers to a mixture of various types of wastewater, including organic and inorganic salts. This type of wastewater mainly comes from industrial production such as food processing plants, pharmaceutical plants, and chemical plants. These types of wastewater not only have high salt content, but also contain high concentrations of organic matter. If discharged directly without treatment, it will inevitably cause great harm to aquatic organisms, drinking water, and industrial and agricultural production water.

The common characteristics of this type of concentrated wastewater are that it cannot be simply treated by biochemical methods, and the physical and chemical treatment process is complex, with high treatment costs, making it a recognized high difficulty wastewater treatment in the sewage treatment industry.

2. Haipu customized processing technology

In order to achieve the standard discharge of high grade mixed salt wastewater, MVR evaporation or three effect evaporator is commonly used. Specifically, the mixed salt wastewater enters the evaporation device and undergoes a concentrated crystallization process through evaporation and condensation, separating into desalinated water and concentrated crystal slurry waste liquid. Salt and some organic matter can be crystallized and separated as solid waste treatment, and desalinated water can be returned to the production system to replace softened water for utilization. However, in practical applications, due to the high organic content in mixed salt wastewater, problems such as evaporator blockage, low salt evaporation efficiency, and dark salt evaporation color often occur, which pose challenges to the stable operation of enterprises.

The mixed salt wastewater adsorption process developed by Jiangsu Haipu Functional Materials Co., Ltd. pretreats the wastewater before salt evaporation, converting the organic salts in the wastewater into organic acids, and then adsorbing and removing the majority of the organic acids. The effluent after adsorption treatment is mostly inorganic salts, greatly improving the stability of the subsequent evaporation system operation. The adsorbent material is desorbed and regenerated through an eluent, and the desorbed organic salts can be returned to the workshop for recycling. On the one hand, this process reduces the chromaticity of salt evaporation, transforming solid salt from hazardous waste to solid waste, reducing the operating costs of enterprise production. On the other hand, it recycles organic salts, providing an effective solution for the treatment of mixed salt wastewater.

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has achieved international leading levels in ion exchange technology and adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

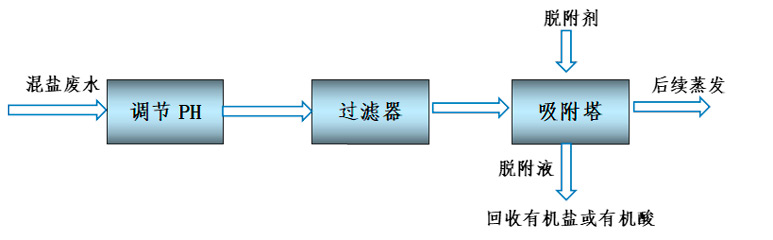

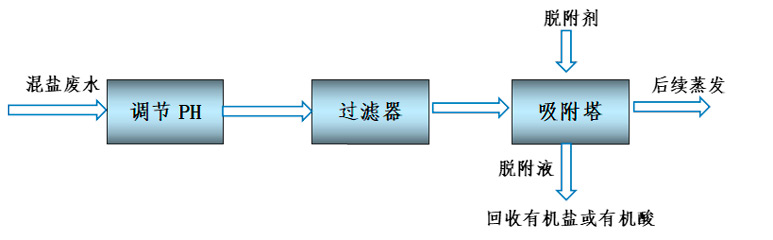

When using Haipu's adsorption process to treat mixed salt wastewater, chemicals are first added to convert organic salt components into organic acids, and then suspended particulate matter is filtered and removed before entering the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb the organic acids in the wastewater on the surface of the material, significantly reducing the COD of the effluent. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The adsorption treatment process flow of mixed salt wastewater is shown in the following figure.

Figure 1 High salt wastewater treatment process

3. Case Introduction

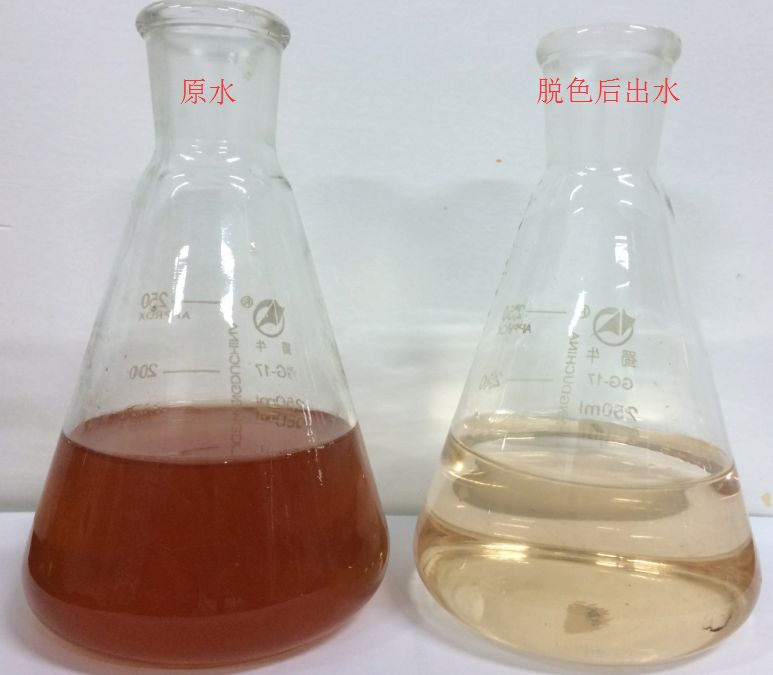

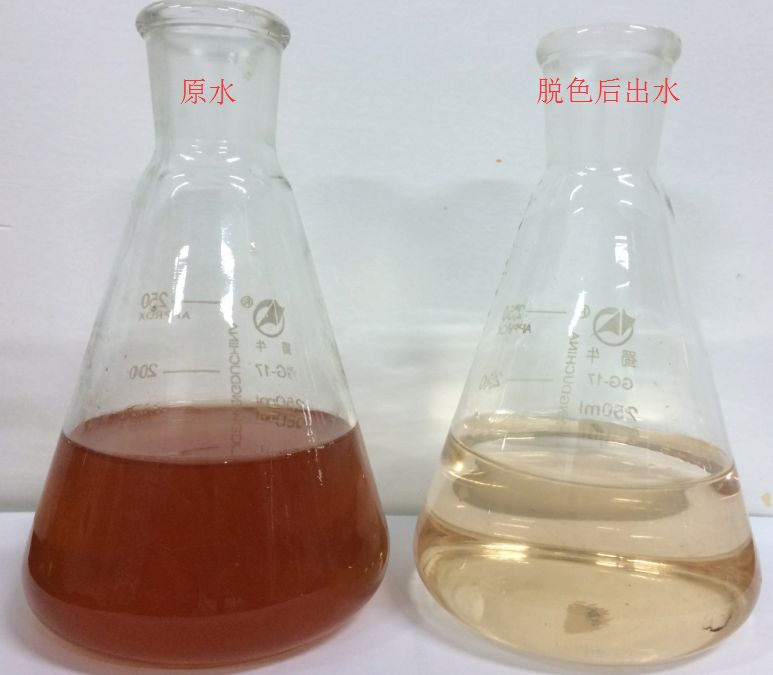

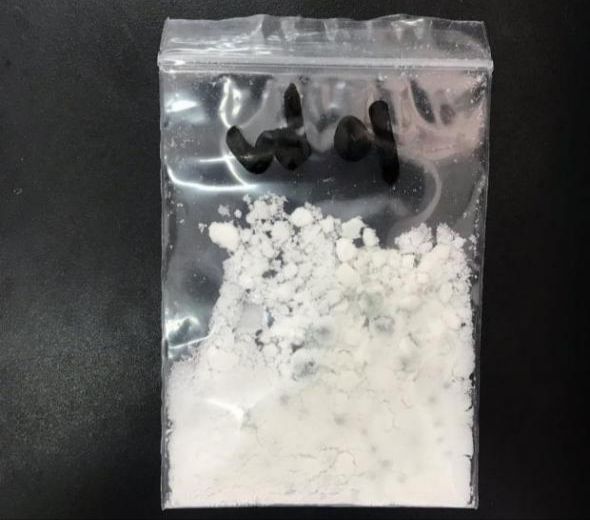

This newly built mixed salt wastewater adsorption treatment facility has a total designed wastewater treatment capacity of 100m 3/d. The wastewater is mixed salt wastewater from the factory, which is dark in color and evaporates into brown. The solid waste treatment cost is high. Haipu has customized the process design for the wastewater, and the wastewater design indicators are shown in the table below.

Table 1 Wastewater Design Parameters Table

| Indicator | Water volume(m³/d) | Color (mg/L) |

| Absorb incoming water | 100 | Brown red |

| Adsorbed water | ~100 | Light Red |

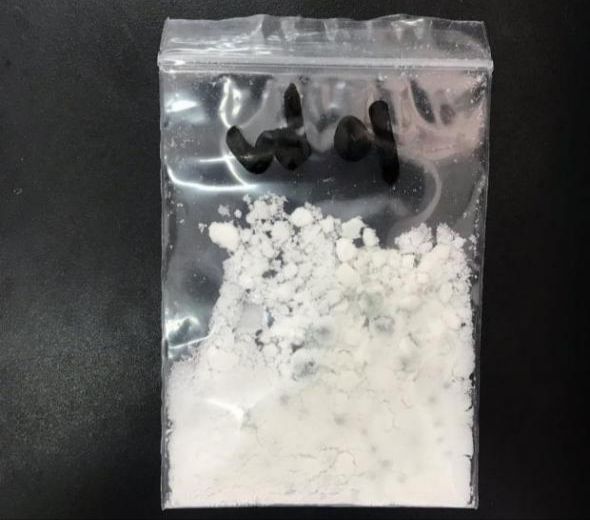

| Steam salt in the effluent |

| White |

Figure 2 Appearance of raw water (left) and effluent (right)

Figure 3: Salt evaporation from effluent

Haipu's customized adsorption process can deeply adsorb and remove organic matter from wastewater, reduce the color of the effluent, improve the stability and quality of the subsequent salt evaporation system, reduce the production and operation costs of the enterprise, and provide guarantee for stable production on site for customers.

4. Advantages of adsorption method

Deeply removing organic matter from wastewater, reducing COD and chromaticity of adsorbed effluent, can ensure white salt evaporation in effluent, and improve the stability of subsequent evaporation systems.

Separate and recycle organic salts from mixed salt to achieve the goal value of turning waste into treasure.

Using specially modified adsorption materials, with large adsorption capacity, low equipment investment, and low operating costs.

The process flow is simple and can achieve full automation operation, making operation and maintenance convenient.

It can achieve multi-layer layout, small footprint, and short installation cycle.

CN

CN