With the development of metallurgical and electronic industries, a large amount of copper containing wastewater has been generated. Copper containing wastewater has high economic value, but it is harmful to both humans and the environment. If copper containing wastewater can be recycled before discharge, it can not only solve the problem of copper pollution to the environment, but also save resources and have certain economic benefits. Usually, the copper ion content of acidic copper plating cleaning water is 2-5 grams per liter of copper, and it contains 1-3 grams per liter of sulfuric acid. We collectively refer to this waste liquid as acidic low copper waste liquid. At present, the treatment of copper containing wastewater in China mainly focuses on high concentration copper containing waste liquids, and research on waste liquids with low copper ion content generated in industry production is relatively limited.

At present, there are several main methods for treating waste liquids with low copper ion concentration.

1. Generate high copper sludge

This method involves adding copper containing wastewater to an alkaline liquid, precipitating the copper in the solution as copper mud, and discharging the waste liquid. The copper mud obtained by this method has low grade and low product price. At the same time, the waste liquid after producing copper mud needs to be discharged, which causes secondary pollution to the environment.

2. Neutralization crystallization

This method is to produce high-quality copper sulfate by first neutralization, centrifugal filtration, re neutralization crystallization, screening and dehydration of acid and alkali copper containing waste liquids. This method yields the product copper sulfate, which has a higher added value than copper paste. But after the copper in the waste liquid is recovered in the form of copper sulfate, the wastewater also needs to be discharged, polluting the environment.

3. Preparation of high-purity copper oxide powder from acidic copper containing waste liquid

Recovering copper from acidic copper containing waste liquid in the form of copper oxide. The main problem is that wastewater needs to be discharged externally.

4. Electrolytic recovery of copper

Recovering copper from copper containing waste liquid by electroplating copper. The product obtained is electroplated copper, with a high selling price and good economic benefits. But the copper in the solution can only be reduced to about 1~3g/l by electrodeposition, and it needs to be further treated in the wastewater treatment station. This method cannot handle acidic copper plating cleaning water with low copper content and other low copper waste liquids.

The biggest problem with the existing technologies for low concentration acidic copper containing wastewater is the low degree of resource recovery and significant secondary pollution to the environment. A large amount of waste liquid is discharged into the environment after simple treatment, causing continuous pollution to the environment such as copper and COD.

5. Haipu customized processing technology

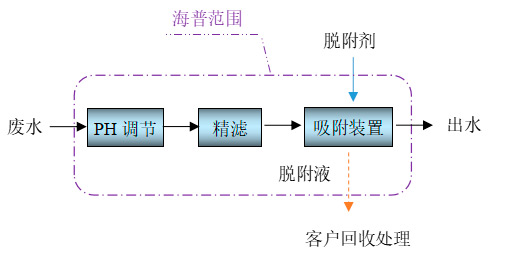

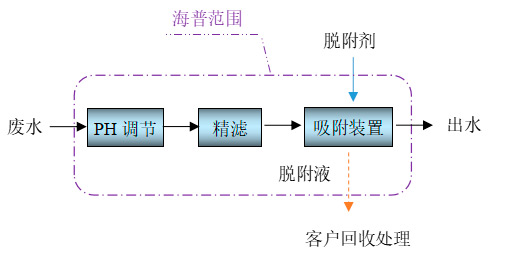

The acidic low copper waste liquid treatment process developed by Jiangsu Haipu Functional Materials Co., Ltd. selectively adsorbs and enriches copper in copper acid water into the adsorption material, thereby achieving the goal of separating copper ions. The adsorbed acid copper content is greatly reduced, meeting the requirements of subsequent steps. The desorption solution is a concentrated copper ion solution several times, which can be recycled and processed by customers.

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has achieved international leading levels in ion exchange technology and adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

When using Haipu's adsorption process to treat acidic low copper waste liquid, the raw water of low concentration copper containing wastewater is lifted by an adsorption pump and enters the fine filter to intercept suspended solids and fine particles, preventing impurities from entering the adsorption material and affecting the adsorption performance. The filtered wastewater is then sent to an adsorption tower equipped with special adsorption materials for adsorption. After adsorption saturation, specific desorption agents are used to desorb the adsorption materials, allowing them to regenerate and resume adsorption. This process continues in a continuous cycle. The effluent can be discharged or enter the subsequent treatment process, and the high concentration desorption solution can be recycled and treated by customers.

Figure 1 Process Flow Diagram

6. Case Introduction

The Samsung Electronics copper containing wastewater treatment project has a total designed wastewater treatment capacity of 10000m ³/year, with blue effluent, pH 1.75, copper ion concentration of 3531ppm, TDS concentration of 389000ppm. The effluent does not meet the requirements for subsequent treatment and cannot meet the stable production needs of the enterprise. Haipu has customized the process design for the wastewater, and the wastewater design indicators are shown in the table below.

Table 1 Wastewater Design Parameters Table

| Indicator | Water volume t/a | pH | Copper ion (mg/L) | TDS(mg/L) |

| Original incoming water | 10000 | 1~2 | ≤3531 | ≤389000 |

| Adsorbed water | 10000 | 3~4 | ≤0.5 | ≤173000 |

| Desorption fluid | ~2.1 | Strong acid | 35000~40000 |

|

| Design running time | Running for 6 hours every day |

The laboratory trial results are as follows:

Table 2 Adsorption Treatment Data

| Batch | Adsorption capacity | Adsorption flow rate | Copper content in effluent | Copper content in desorption solution |

| 1 | 13BV | 2BV/ h | 0.058ppm | 33750ppm |

| 2 | 13BV | 2BV/ h | 0.082ppm | 33278ppm |

| 3 | 13BV | 2BV/ h | 0.413ppm | 32802ppm |

| 4 | 13BV | 2BV/ h | 2.418ppm | 39728ppm |

| 5 | 13BV | 2BV/ h | 0.470ppm | 36884ppm |

| 6 | 13BV | 2BV/ h | 0.240ppm | 40192ppm |

Appearance of processing effect:

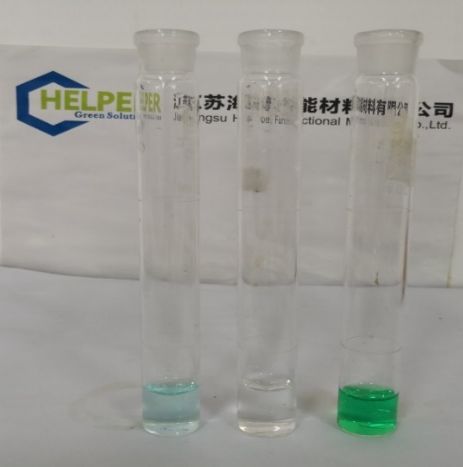

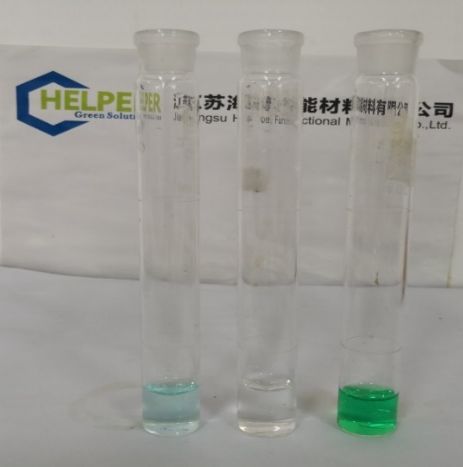

Figure 2 shows the raw water, adsorbed effluent, and desorption solution in sequence

After being treated with a special adsorbent, the effluent of copper wastewater is colorless, with a copper content of ≤ 0.5ppm. The recovered copper content in the desorption solution reaches 4%.

7. Advantages of adsorption method

Effectively reducing the concentration of copper ions in the effluent can ensure that the effluent meets the discharge standards or the operational requirements of subsequent processes;

Using specially modified adsorption materials, with large adsorption capacity, low equipment investment, and low operating costs;

The process flow is simple and can achieve full automation operation, making operation and maintenance convenient;

It can be arranged in multiple layers, occupying a small area and having a short installation cycle;

High concentration copper containing desorption solution can be recycled, which has significant environmental and economic benefits.

CN

CN