In recent years, with the increased efforts in environmental protection by the state, the discharge standards for corresponding pollutants in wastewater have been raised, and wastewater treatment technologies have been continuously innovated. As a key industry for pollution discharge, the treatment methods for industrial ammonia nitrogen wastewater are particularly crucial.

When the ammonia nitrogen concentration in wastewater exceeds 500 mg/L, it is referred to as high-concentration ammonia nitrogen wastewater; otherwise, it is considered medium to low-concentration ammonia nitrogen wastewater. Due to the limitations of process conditions and water quality indicators, different types of wastewater require different treatment methods.

China has included ammonia nitrogen in the “12th Five-Year Plan” for environmental pollutant control indicators, setting stricter standards for wastewater discharge in the smelting industry. The direct discharge standard for ammonia nitrogen in the lead-zinc industry must be controlled below 8 mg/L.

*Image source: Internet

Ammonia Nitrogen Wastewater Treatment Technology

Different treatment technologies are used for different categories of ammonia nitrogen wastewater. For high-concentration ammonia nitrogen wastewater, common methods include air stripping-biological method, air stripping-breakpoint chlorination method, and chemical precipitation-biological method.

01 Air Stripping Method

Air stripping involves introducing air into the wastewater to promote the transfer of volatile solutes from the liquid phase to the gas phase, ultimately achieving wastewater treatment.

02 Chemical Precipitation Method (Magnesium Ammonium Phosphate Precipitation Method)

This method involves adding reagents containing Mg²⁺ and PO₄³⁻ to ammonia nitrogen wastewater, causing the ammonia nitrogen and phosphorus in the wastewater to precipitate as struvite (magnesium ammonium phosphate), while also recovering nitrogen and phosphorus from the wastewater.

For low-concentration ammonia nitrogen wastewater, considering cost and efficiency, adsorption and biological methods are commonly used.

03 Biological Method

In the biological method, ammonia nitrogen in wastewater undergoes a series of reactions such as nitrification and denitrification by various microorganisms, ultimately generating nitrogen gas, thereby achieving removal. For wastewater with high biodegradability (BOD/COD > 0.3), ammonia nitrogen can be removed through biological methods.

04 Adsorption Method

Adsorption is a process where the concentration of one or more substances (called adsorbates) changes automatically on the surface of another substance (called adsorbent). Essentially, it is a mass transfer phenomenon from the liquid or gas phase to the solid surface.

The adsorption method is one of the promising methods for treating low-concentration ammonia nitrogen wastewater.

05 Breakpoint Chlorination Method

Breakpoint chlorination is a commonly used denitrification process in wastewater treatment. The principle involves adding chlorine to ammonia nitrogen wastewater to a critical point to oxidize ammonia nitrogen into nitrogen gas.

Additionally, there are new biological denitrification technologies such as short-cut nitrification-denitrification, anaerobic ammonia oxidation, and membrane technologies such as reverse osmosis and electrodialysis.

However, due to different water quality indicators and process conditions, the treatment technologies used for different types of wastewater vary significantly.

Here, we introduce a case where an enterprise used our special adsorbent materials in combination with the adsorption process to treat ammonia nitrogen wastewater.

Project Case Overview

Project Overview:

The enterprise generates ammonia nitrogen wastewater during production, putting significant pressure on its environmentally friendly production. The enterprise aims to reduce the ammonia nitrogen content in the treated wastewater to below 20 mg/L.

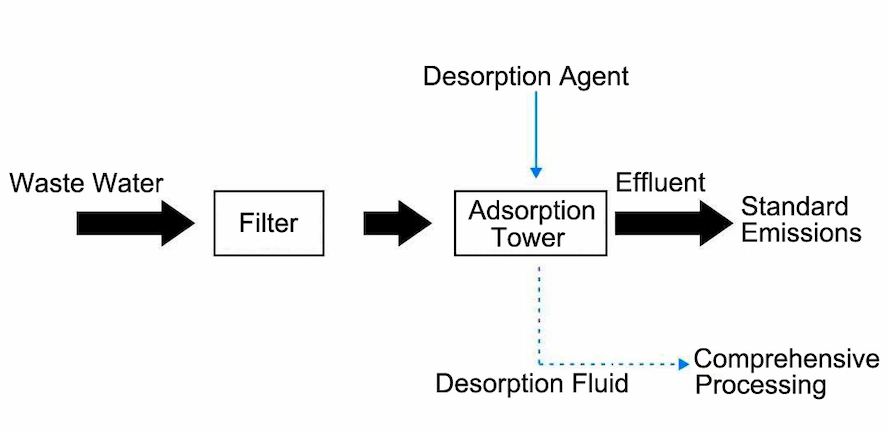

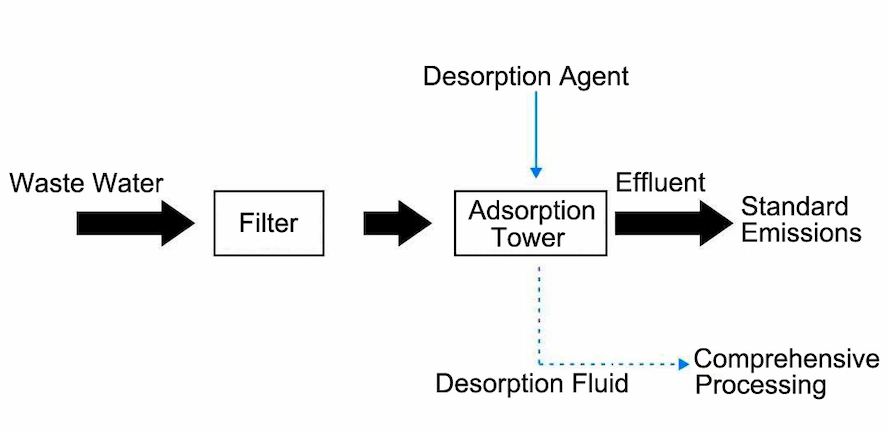

Process Introduction:

When using Haipu’s adsorption process to treat ammonia nitrogen wastewater, the wastewater is pre-filtered to remove suspended and particulate matter, then enters the adsorption tower. The special adsorbent materials in the adsorption tower adsorb the ammonia nitrogen from the wastewater onto the material surface, achieving the removal of ammonia nitrogen from the water.

Process Principle:

The basic principle of this solution is to use the adsorption performance of the adsorbent material to selectively adsorb ammonia nitrogen substances in the wastewater and enrich them in the adsorbent material.

When the adsorption is nearly saturated and the effluent is about to exceed the standard, a specific desorbent is used to desorb the adsorbent material, regenerating it for continued adsorption, thus continuously cycling.

Achieved Treatment Effectiveness

Experimental results show that using the adsorption treatment, the ammonia nitrogen removal rate in the wastewater is consistently above 90%, and the ammonia nitrogen content in the effluent can be controlled below 10 mg/L.

This not only meets the customer’s requirements but also provides a safety margin to effectively prevent fluctuations in the quality of the incoming wastewater from causing non-compliance in the effluent. The ammonia nitrogen adsorption treatment effectiveness and the comparison of influent and effluent are shown below.

| Raw Water Ammonia Nitrogen Content | Treated Water Ammonia Nitrogen Content | Removal Rate |

| 112.1 mg/L | 7.2 mg/L | 93.58% |

| 112.1 mg/L | 7.8 mg/L | 93.76% |

| 112.1 mg/L | 7.8 mg/L | 93.76% |

*Experimental Treatment Data

*Raw Water (Left) and Treated Effluent (Right)

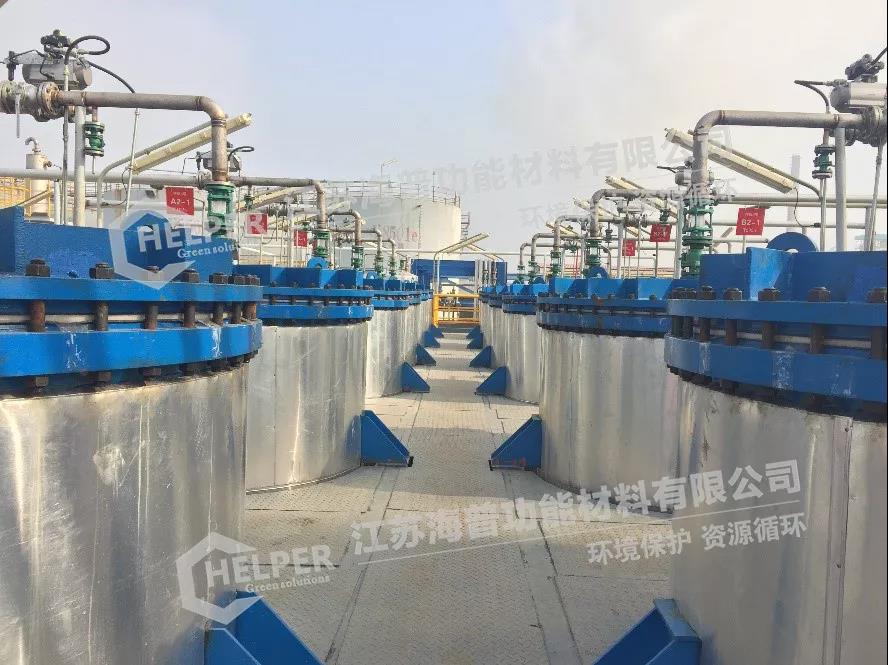

*Haipu Ammonia Nitrogen Wastewater Treatment Project Site 1

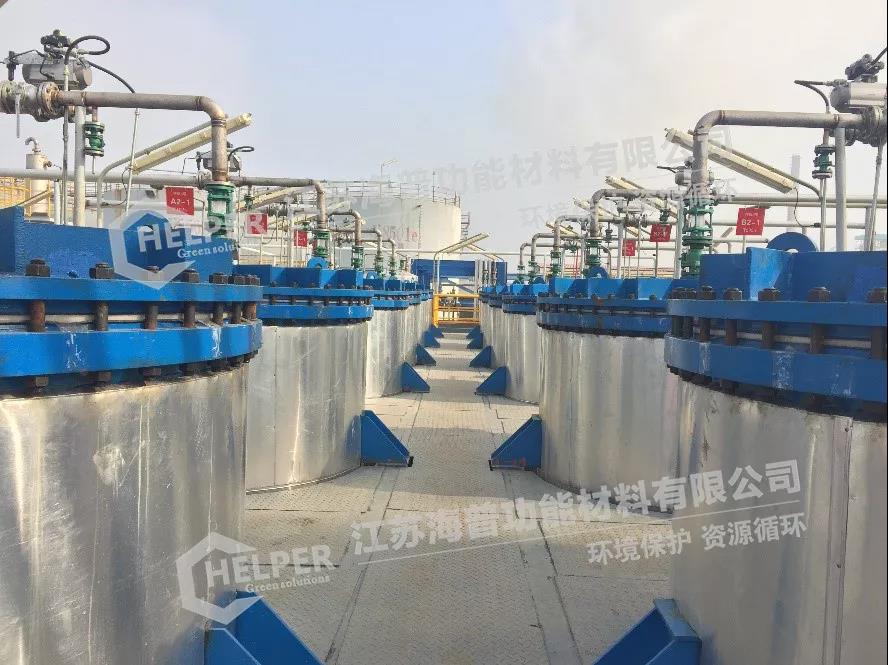

*Haipu Ammonia Nitrogen Wastewater Treatment Project Site 2

Process Characteristics

Currently, the main methods for treating high-concentration ammonia nitrogen in industrial wastewater involve using physical and chemical methods for pretreatment, followed by other methods for subsequent treatment. Although good treatment results can be achieved, issues such as scaling and secondary pollution still exist.

Additionally, high concentrations of ammonia nitrogen inhibit the nitrification process in biological methods. Using the adsorption method to treat ammonia nitrogen wastewater can efficiently remove ammonia nitrogen, ensuring that the treated wastewater contains less than 20 mg/L, meeting the enterprise’s requirements and reducing the pressure on subsequent wastewater treatment.

Haipu’s supporting adsorption equipment is space-saving, compact in structure, and requires low civil engineering and equipment investment. The desorbent can be reused multiple times with stepwise concentration, resulting in high utilization. The modular component design allows flexible adjustment based on production capacity and easy installation.

Haipu’s strong technical support and extensive engineering application experience provide high-quality ammonia nitrogen wastewater treatment services for customers.

Service Process

1. Laboratory Small-Scale Test The R&D team conducts tests based on customer water samples and provides a detailed water quality test report.

2. On-Site Pilot Test Based on customer needs and scientific data, we provide cost-effective solutions, engineering commissioning, and personnel training.

3. Design and Construction Mainly in the form of fixed beds, saving floor space, and optimizing space layout based on on-site conditions.

4. Engineering Commissioning and Personnel Training Low investment, simple operation, high automation, low operation and maintenance costs, and professional training for operation.

5. After-Sales Service Ensuring customers pass relevant environmental acceptance smoothly, with a professional after-sales team providing 24/7 technical services.

CN

CN