Keywords: sulfonamide wastewater, special adsorption materials, resource recovery

Sulfonamide wastewater is mostly generated in pharmaceutical factories and aquaculture, and this type of wastewater contains recalcitrant organic compounds. If not treated properly, it will cause serious harm to the environment. At present, most of the sulfonamide wastewater in China is generated from chemical and pharmaceutical raw material factories and used for antibacterial processes in aquaculture. Sulfonamide wastewater is not easy to undergo biochemical treatment and can cause serious pollution to the environment when discharged. However, due to the lack of economically effective treatment methods, the discharged wastewater contains a large amount of sulfonamides that are difficult to remove, and the COD value and salt content far exceed the national wastewater discharge standards. Not only does it seriously pollute the ecological environment and endanger human health, but it also causes resource loss and waste, affecting the sustainable development of enterprises.

Synthetic pharmaceuticals are one of the main industries for people's livelihoods, and a large amount of wastewater is generated during the production of sulfonamide drugs. This type of wastewater contains a large amount of difficult to degrade organic compounds, mainly sulfonamides, which are difficult to treat. Sulfonamide is commonly used in the production of various sulfonamide drugs such as paroxetine, sulfapyridine, sulfamethoxazole, sulfamethoxazole, sulfamethoxazole, and sulfamethoxazole. If sulfonamide wastewater is not treated properly, it will have a significant impact on the environment and also cause resource loss and waste.

There are several common treatment processes for this type of wastewater, including:

(1) Physical and chemical processing

The simple physicochemical method mainly targets the large amount of acid containing wastewater discharged during the production process of sulfonamide. To treat this pollution source, waste carbide slag is used as a neutralizing agent to neutralize the acid containing wastewater. Ca (OH) 2 in carbide slag reacts with sulfate ions (SO4 2-) and chloride ions (Cl -) in the wastewater to produce CaSO4 and CaCl2, respectively. The generated sludge is filtered and dehydrated by a plate and frame filter press, and the dry sludge is outsourced for treatment. The physical and chemical treatment of sulfonamide wastewater has a simple process and is easy to industrialize, but the treatment effect is poor and cannot stably meet the standards. It needs to be combined with other advanced processes for further treatment.

(2) Biological treatment

There are many types of sulfonamide drugs, and the by-products in the production process are complex, resulting in a large amount of sulfonamide wastewater with complex components and a large amount of antibacterial organic compounds. It has the characteristics of high organic concentration, high sulfur content, high ammonia nitrogen, and high pH value. When using traditional activated sludge treatment, it requires a large amount of dilution water and the effluent quality is difficult to meet the standards.

Moreover, sulfonamides and their intermediates contained in sulfonamide wastewater are difficult to degrade and have certain toxicity to microorganisms. Therefore, conventional biological methods are difficult to treat. The sequencing batch reactor (SBR), with its unique advantages, has been developed around the world in recent years.

Compared with traditional aerobic biological treatment methods such as activated sludge or oxidation ditch, anaerobic biological treatment has the advantages of small footprint, low operating costs, recyclability of certain bioenergy, low residual sludge volume, and easy treatment and disposal. However, anaerobic reactors are sensitive to toxic substances, and their long start-up cycle and small water treatment capacity limit their application in large-scale sewage treatment projects.

(3) Haipu Special Adsorption Technology

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has significant advantages in ion exchange technology, adsorption technology, and nano inorganic material hybridization technology, achieving the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling.

Currently, the options for treating sulfonamide wastewater are still limited. Through in-depth research, Jiangsu Haipu Functional Materials Co., Ltd. has found that its special adsorbent and supporting adsorption method not only solve the problem of sulfonamide wastewater treatment, but also reduce the cost of outsourcing wastewater treatment and adding new water, making it more economically valuable.

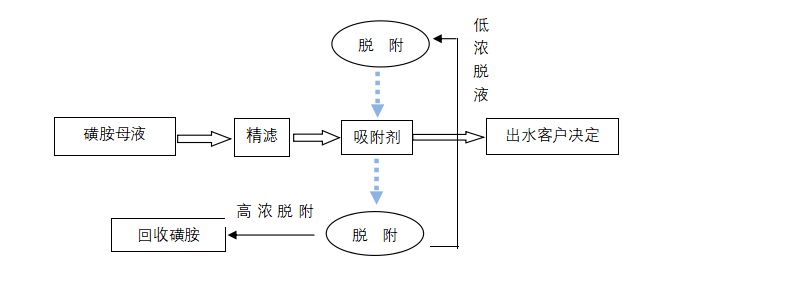

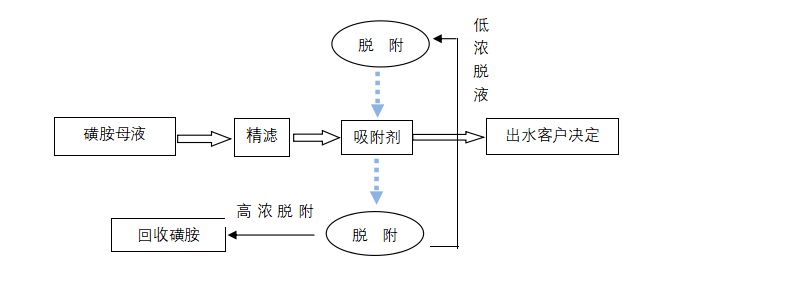

Technological process

The process flow is shown in the figure. The sulfonamide mother liquor first passes through a fine filtration system to intercept the fine suspended solids and particles in the waste, preventing impurities from entering the adsorbent material and affecting the adsorption performance. The filtered wastewater is then sent to an adsorption tower equipped with special adsorption materials for adsorption. After adsorption saturation, the adsorbent material is subjected to desorption regeneration treatment, and the regenerated adsorbent material can be reused. The treatment method for adsorbed water can be determined by the customer, and high concentration desorption solution can be used to recover sulfonamide.

Figure 2-3 Process Flow Chart

Scope of application

Recovery of sulfonamide mother liquor resources

Advantage

Efficiently remove organic and colored substances from wastewater to achieve water reuse;

Special adsorbent materials have high absorption capacity and high concentration ratio, low equipment investment, and low operating costs;

Automated control, easy operation, convenient maintenance, and long service life.

Adsorb sulfonamide in wastewater with high adsorption rate; After adsorption, sulfonamide can be completely resolved from the material, achieving resource recovery.

Adsorption processing data

Case 1 Adsorption of inlet and outlet water data

| Indicator | Sulfonamide (ppm) | PH | Colour | Aminobenzenesulfonic acid (ppm) | Remarks |

| Original incoming water | 4060 | 7.4 | Yellow | 2174 |

|

| Absorb incoming water | 4060 | 7.4 | Yellow | 2174 |

|

| Adsorbed water | <150 | 7.2 | Slightly yellow | / |

|

| Desorption fluid | / | Alkalinity | / | / | Recycling sulfonamide |

CN

CN