Recently, the Shanghai Ecology and Environment Bureau, together with the Shanghai Development and Reform Commission and the Shanghai Finance Bureau, formulated the "Special Support Measures for Deepening the Treatment of Volatile Organic Compounds in Key Industry Enterprises in Shanghai".

The method specifies that the total subsidy amount for enterprises is the sum of the subsidy amounts for each governance project. If an enterprise completes 90% or more of the "recommended" governance tasks, a 10% bonus will be given to the total subsidy amount. The total subsidy amount for a single enterprise shall not exceed 12 million yuan.

Highlighting the effective management of VOCs is also a key direction for Shanghai's air pollution control.

Efforts to Control VOCs in Shanghai

In 2014, Shanghai launched the first round of VOCs control and was the first in the country to introduce the "One Factory One Plan", with a focus on end-point treatment.

The second round of governance was launched in 2020, adopting refined control measures throughout the entire process, including source reduction, process control, end of pipe treatment, special limits, and fine management.

At the same time, low VOCs substitution demonstrations were carried out, actively exploring VOCs protocol emission reduction and reduction substitution pilot systems, and constructing innovative emission reduction models with hierarchical management.

A total of 8 local standards related to VOCs control have been released, and technical specifications for key industries such as petrochemicals, shipping, and printing have been issued, establishing a relatively complete legal and regulatory standard system.

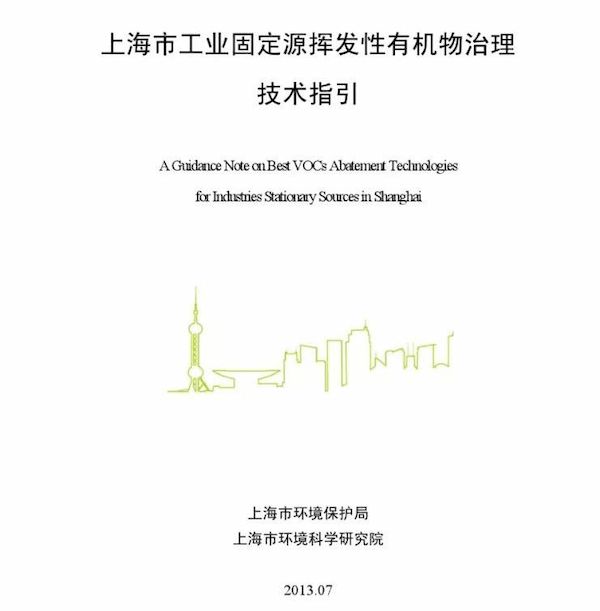

Issuing the "Technical Guidelines for VOCs Control of Industrial Fixed Sources in Shanghai" to provide technical support for VOCs control; Introduce the "Special Support Measures for Pollution Control Projects of Industrial Volatile Organic Compound Emission Reduction Enterprises in Shanghai" to encourage enterprises to take the lead in pilot projects.

It is reported that Shanghai is currently formulating the "Special Support Measures for Deepening the Management of Volatile Organic Compounds in Key Industry Enterprises in Shanghai", aiming to encourage and guide enterprises to carry out deep VOCs emission reduction throughout the entire process and in all aspects.

Special Support Measures for Deepening the Treatment of Volatile Organic Compounds in Key Industry Enterprises in Shanghai

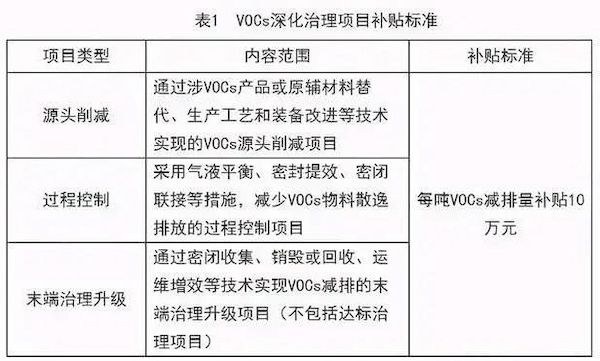

The measures released by Shanghai this time apply to the VOCs deepening treatment projects identified in the "One Factory One Plan (Version 2.0)" implemented by relevant enterprises in accordance with the requirements of the "Notice" from January 1, 2020 to December 31, 2022, including source reduction, process control, and end-point treatment upgrading projects.

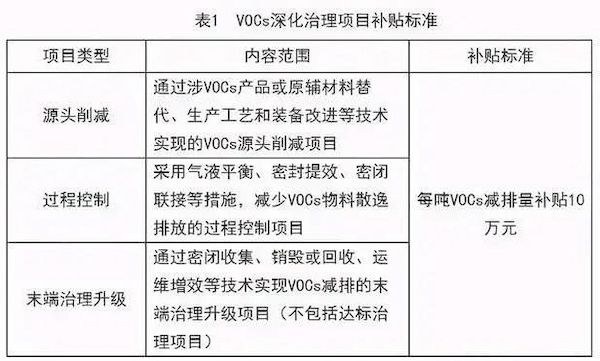

In order to encourage enterprises to implement high-level VOCs deepening governance projects and reduce VOCs emissions more, faster, and better, this method classifies and levels subsidies based on emission reductions.

Among them, the emission reduction is determined according to the "Calculation Method for Emission Reduction of Industrial Volatile Organic Compound Pollution Control Projects in Shanghai (Trial)" (Hu Huan Qi [2021] No. 25), and the subsidy standards are detailed in the table.

Requirements for applying for relevant subsidies

*Subsidy standards

The governance enterprises applying for subsidies should meet the following conditions simultaneously:

(1) Complete the preparation of the "One Factory One Plan (2.0 version)" for VOCs control, and carry out the plan in accordance with the requirements of the Notice and pass expert evaluation; Develop and complete the 'Implementation Plan for Governance Tasks'.

(2) Fully complete the "requirements" and "objectives" governance tasks listed in Annex 4 of the Notice, with a completion rate of no less than 70% for the "recommended" governance tasks;

(3) After the implementation of the governance project, the VOCs emission reduction of the enterprise shall not be less than 10 tons/year, or the emission shall be reduced by 20% or more compared to before the governance;

(4) The source reduction project is implemented through partial or complete renovation of production facilities, with clear and fixed physical boundaries, and does not have dual-use or interchangeability with the original VOCs materials or product production; The end of pipe treatment upgrade project adopts the treatment technology recommended by the "Shanghai Industrial Fixed Source Volatile Organic Compound Treatment Technical Guidelines", and the removal effect of VOCs pollutants has been further improved on the basis of the original requirements (Shanghai Industrial Volatile Organic Compound Emission Reduction Enterprise Pollution Control Project Special Support Operation Measures "Hu Environmental Protection Prevention [2015] No. 325);

(5) The projects applying for special fund support under these measures have not received subsidies from other municipal government funds in this city;

(6) Good credit status, no serious dishonesty record, and no record of VOCs environmental violations during the subsidy application period.

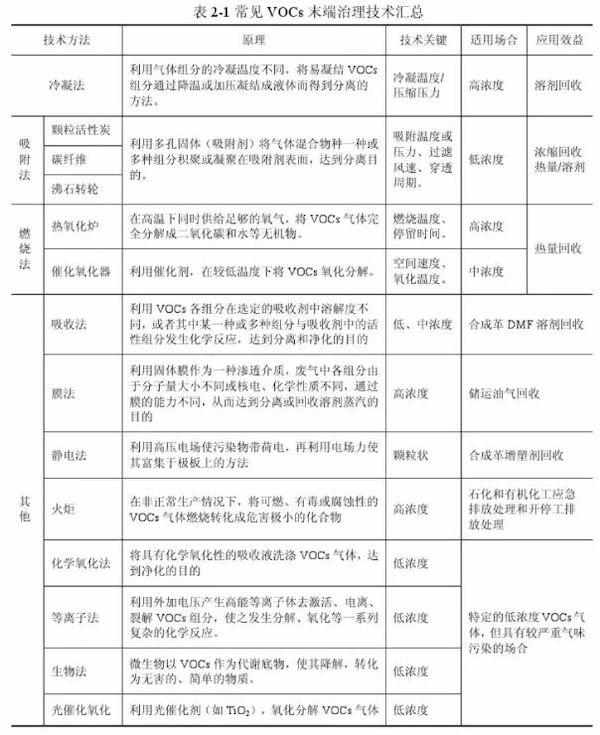

*Common VOCs End of pipe Treatment Technologies in Technical Guidelines

Recommended VOCs End of pipe Treatment Technologies in Technical Guidelines

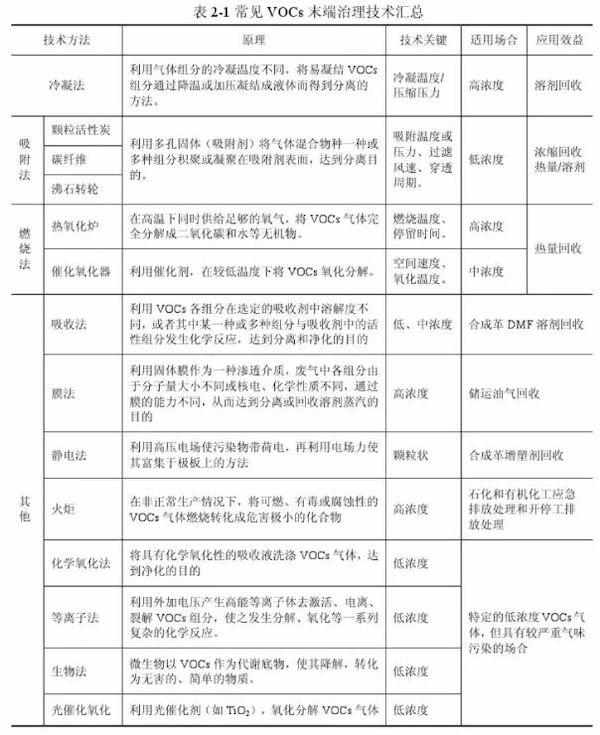

According to the "Technical Guidelines for the Treatment of Volatile Organic Compounds from Industrial Fixed Sources in Shanghai", from the perspective of resource recycling, solvent recovery is the best choice, and the best method for solvent recovery is adsorption, in which various adsorbents are relatively mature technologies.

The condensation method is the ultimate means of solvent recovery and a commonly used method for pre-treatment of high concentration VOCs and low air volume gases. However, the concentration of VOCs after condensation still cannot meet the direct emission requirements, so it needs to be combined with other methods.

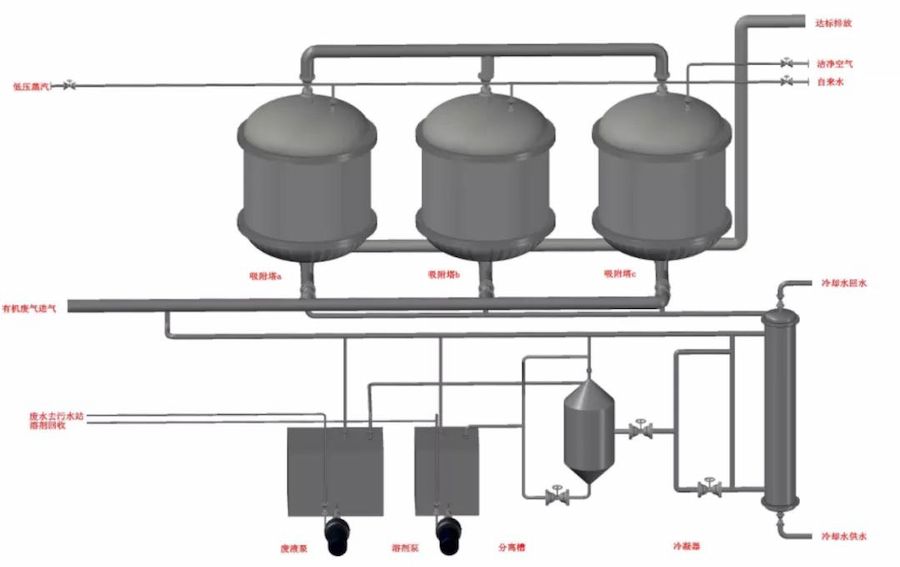

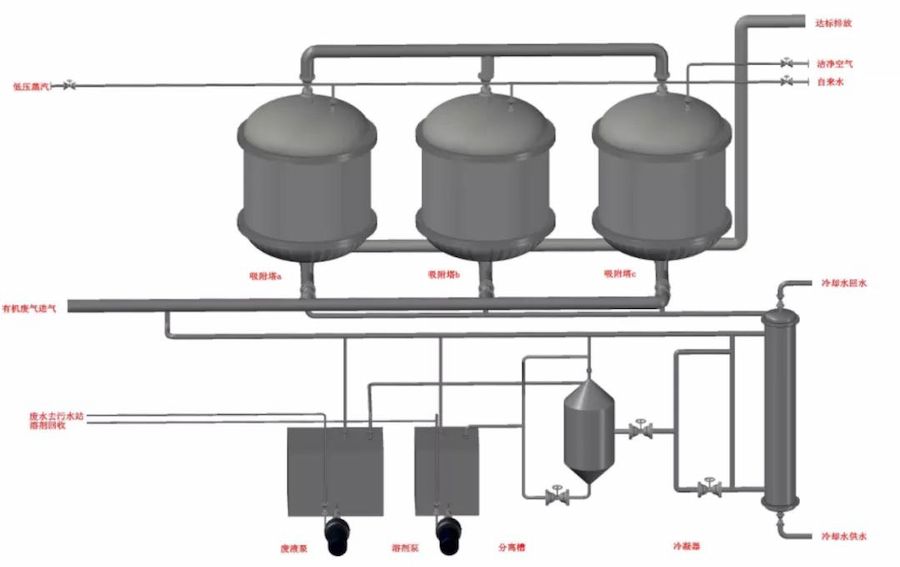

In order to upgrade the VOCs end of pipe treatment of enterprises according to the recommended technologies in the technical guidelines to meet relevant application standards, the HDV type polymer nano adsorbent developed by Haipu, combined with relevant equipment and condensation methods, can be recycled for the resource utilization of VOCs waste gas end of pipe treatment, which meets the requirements of subsidy application.

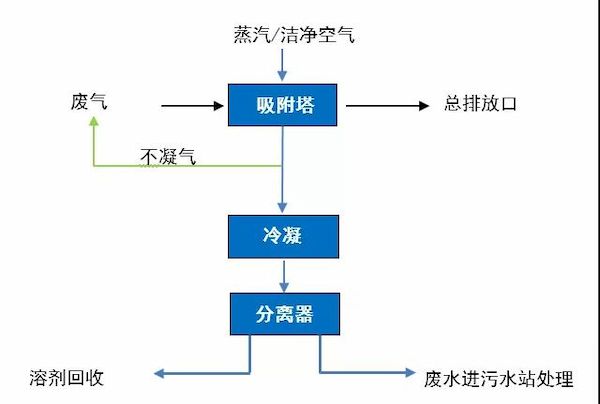

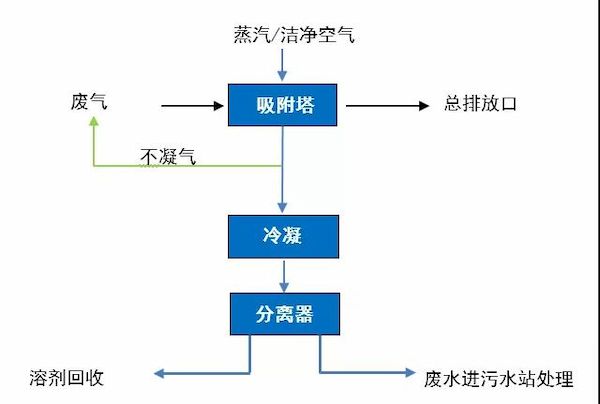

In terms of processing principle, the relevant VOCs waste gas is first extracted by a vacuum pump and then subjected to secondary condensation. The condensed and liquefied components are received in a storage tank, and the uncondensed waste gas is connected to an adsorption tower containing nano adsorbents for adsorption and enrichment. After adsorption, the waste gas can meet the emission standards.

After the adsorbent is saturated with adsorption, it is blown off. The mixture of blown off components and water vapor is then condensed and liquefied, and allowed to settle and separate into layers. It can be separated and recovered to achieve the resource cycle emphasized in the technical guidelines.

This nano adsorbent has the following advantages:

(1) Controllable pore structure and high pore volume;

(2) Has good physical and chemical stability, is resistant to acid, alkali, and organic solvents, has high thermal stability and mechanical strength, and is wear-resistant;

(3) The surface exhibits high hydrophobicity, and humidity has no effect on adsorption performance;

(4) Easy to regenerate and stable adsorption performance;

(5) No hazardous waste is generated without the need for replacement.

*Model of VOCs treatment adsorption process equipment

*On site VOCs terminal treatment adsorption process project

Related subsidy application procedures

CN

CN