In recent years, with the development of industry, new problems have emerged in water treatment and water pollution control.

Due to the presence of some biologically recalcitrant or toxic organic pollutants (such as pesticides, synthetic detergents, and certain dyes) in industrial wastewater.

At the same time, in order to protect the environment and water resources, as well as to ensure the reuse of treated polluted water, environmental protection and relevant departments have formulated strict standards and laws.

In many cases, industrial wastewater must undergo tertiary deep treatment to meet the requirements of water pollution control and wastewater reuse.

Application of Ozone in Wastewater Treatment

Ozone treatment of wastewater, as one of the effective methods for deep treatment of wastewater, has a series of advantages such as strong oxidation ability, fast reaction speed, convenient use, and no secondary pollution.

It can not only oxidize inorganic substances in water, but also oxidize organic substances that are difficult to biodegrade. It is widely used in the treatment of industrial organic wastewater, cyanide containing wastewater, phenol containing wastewater (including phenol, triphenylphenol, cresol, xylenol, etc.), oily wastewater, and other wastewater.

These mainly come from industries such as petroleum, petroleum refining, coal chemical, fine chemical, pharmaceutical, pesticide, rubber, textile printing and dyeing wastewater. Due to the wide range of effects of ozone on various organic compounds in the above-mentioned wastewater (which can remove their COD) and its strong oxidative bleaching effect (which can significantly reduce the color of water), it has been widely valued.

Upgrading the Blue Sky Defense War: Ozone will become a key focus of governance during the 14th Five Year Plan period, and its prospects for use in wastewater treatment are bleak.

However, when using ozone for treatment, due to its low solubility, low utilization rate, and poor stability in water, it can only oxidize and decompose some organic pollutants, and it is difficult to completely oxidize and decompose many organic pollutants. In addition, the high cost of ozone generation also limits its application in wastewater treatment.

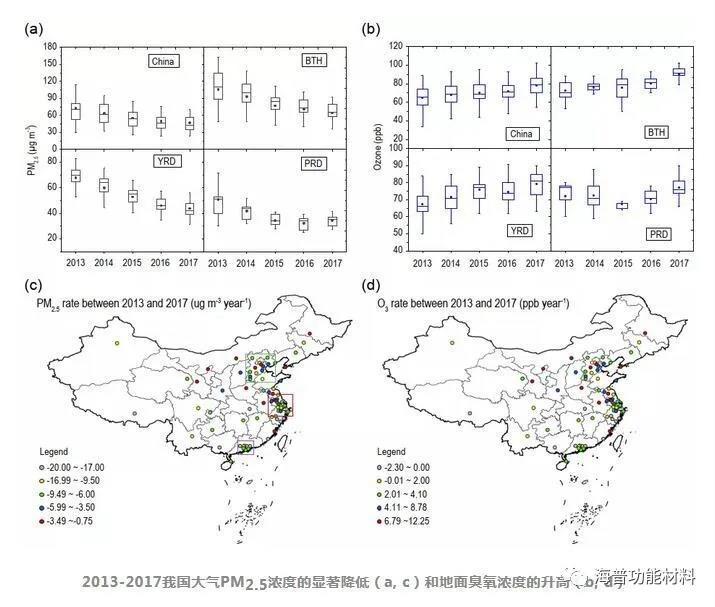

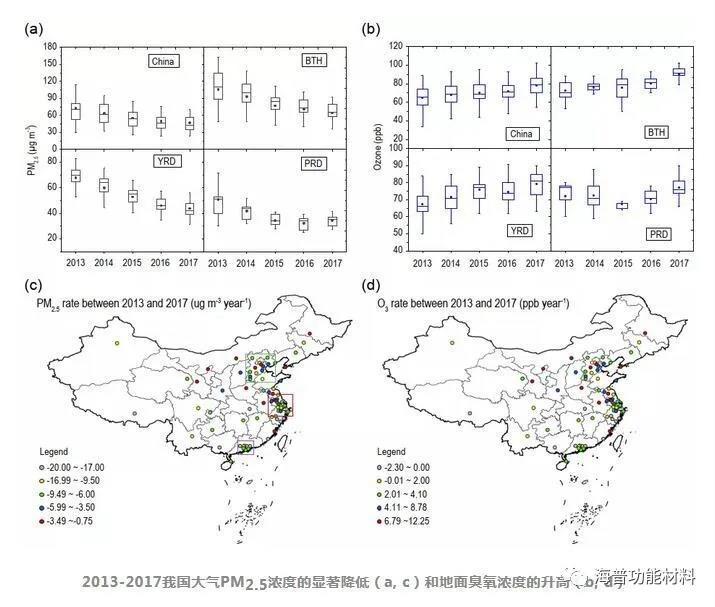

Meanwhile, in recent years, the national air quality has continued to improve, but ozone has become the primary pollutant affecting summer air quality. Data shows that in 2019, ozone concentrations in 337 cities across the country increased by 6.5% year-on-year.

The number of days with ozone as the primary pollutant exceeding the standard in China accounts for 41.8% of the total number of days exceeding the standard, second only to PM2.5 (fine particulate matter) which accounts for 45%.

Summer ozone pollution has become an important "roadblock" in winning the battle to defend the blue sky, and autumn and winter PM2.5 pollution have become the "two big mountains" blocking us.

Therefore, in the practical application of wastewater treatment, the treatment method should be selected reasonably based on the water quality and quantity of the wastewater, combined with the latest policy guidance.

Say goodbye to ozone, Haipu customized adsorption process replaces ozone in wastewater treatment

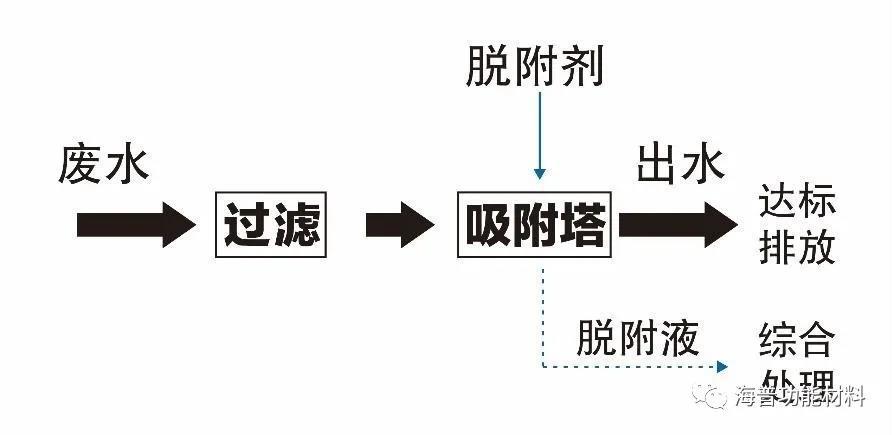

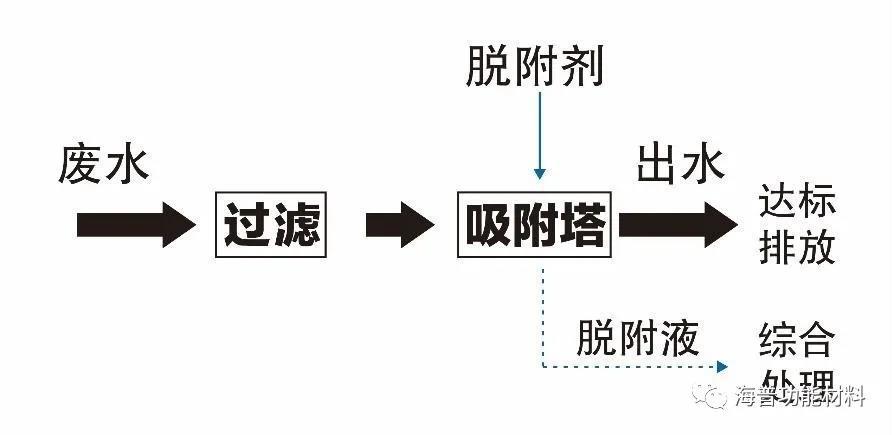

The principle of Haipu adsorption process is to use the special adsorption materials developed by our company to efficiently remove the components or substances to be removed. The adsorption materials can be efficiently regenerated and cycled for a long time.

Process flow of Haipu adsorption method for wastewater treatment

Especially for high concentration organic industrial wastewater that is difficult to biodegrade in coal chemical and petrochemical industries, after physical and chemical pretreatment, biochemical treatment, etc., the effluent COD is still much higher than the discharge requirements, and the chromaticity is high, requiring further treatment.

In addition, wastewater from agricultural, pharmaceutical, printing and dyeing industries usually has complex components, multiple types and high concentrations of organic pollutants, high and fluctuating COD values, significant differences in COD values, high salt concentration, deep color, high toxicity, and difficult biodegradation, making it a difficult industrial wastewater to treat.

In the case of uncertain prospects for the use of ozone oxidation method, Haipu customized adsorption process can solve the problems of wastewater treatment for chemical enterprises in various industries, provide customized solutions, treat these wastewater problems, and effectively solve the environmental pressure of enterprises.

Haipu customized adsorption process treatment effect

Design a wastewater treatment process for 4000t/d biochemical effluent from a coal chemical enterprise to solve the problems of high COD and chromaticity in the enterprise's wastewater biochemical effluent. The adsorbed effluent is reused in the production process after subsequent RO treatment, effectively improving RO treatment efficiency, avoiding RO membrane pollution, frequent replacement, and low operating costs.

| Raw water COD | COD in effluent | Removal rate | Appearance of water outlet |

| 200mg/L | 48.4mg/L | 76% | Near colorless |

| 200mg/L | 47.9mg/L | 76% | Near colorless |

Adsorption inlet and outlet water data

A certain agricultural chemical enterprise in Shandong requires the COD content in the treated wastewater to be less than 500mg/L. Experimental treatment results show that using adsorption treatment can stabilize the COD content in the wastewater to be less than 500mg/L.

While ensuring compliance with customer requirements, leaving a certain safety margin can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent. The wastewater adsorption treatment effect is shown in the table.

| Raw water COD | COD in effluent | Removal rate |

| 15600mg/L | 400mg/L | 97% |

| 15300mg/L | 350mg/L | 98% |

| 16000mg/L | 420mg/L | 97.80% |

Adsorption inlet and outlet water data

300t/d heterocyclic wastewater from a chemical group in Jiangsu: COD content is 45000mg/L, reduced to 3000mg/L, with a removal rate of 93.3%. At the same time, it removes difficult to biodegrade heterocyclic organic compounds, improves biodegradability, and provides guarantees for subsequent biochemical standard treatment.

Adsorption inlet and outlet water data

Practical application case of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

On site application demonstration of Haipu customized adsorption process

The core advantages of Haipu customized adsorption process

Haipu customized adsorption treatment process is an economical and effective method for treating wastewater, with the following advantages:

(1) Developing a series of special adsorption materials based on wastewater from different industries can ensure the stability and compliance of wastewater or provide guarantees for RO water reuse, effectively solving the environmental pressure on enterprises;

(2) Conduct experiments on the sampling samples of wastewater generated on the enterprise site, based on research and development experiments and data, and customize the design accordingly. The matching degree between wastewater and process is high, ensuring industrial scaling up effect;

(3) The equipment occupies less land, has a compact structure, requires less investment in civil engineering and equipment, uses desorption agents multiple times and gradually concentrates them, has a high utilization rate, and has low operating costs;

(4) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install;

(5) Advanced and mature technology, no secondary pollution, strong technical support, and rich engineering application experience.

CN

CN