In recent years, with the rapid development of the pharmaceutical industry, pharmaceutical wastewater has become one of the serious sources of pollution. The demand for pharmaceutical wastewater treatment is increasing. Pharmaceutical wastewater has complex components, multiple types and high concentrations of organic pollutants, high and fluctuating COD values, large differences in COD values, high salt concentration, deep color, and contains difficult to biodegrade and toxic substances. It is one of the more difficult industrial wastewater to treat. How to treat this type of wastewater and ensure that it meets the discharge standards is a difficult problem for environmental protection today.

According to the production requirements of the enterprise and combined with the characteristics of the high salt wastewater, our company's developed special adsorption material for high salt wastewater is used to adsorb and treat the wastewater. The color of the adsorbed effluent is significantly reduced, high boiling point organic matter is efficiently removed, and the distilled salt in the effluent is white, which can meet the customer's requirements. Based on this, this technical solution is issued for reference by the enterprise.

Below, Jiangsu Haipu Functional Materials will provide a detailed introduction to the characteristics and treatment and recycling methods of pharmaceutical wastewater, hoping to be helpful to you.

1. Current situation and challenges in pharmaceutical wastewater treatment:

In the production of pharmaceuticals, different types of wastewater are generated, among which organic wastewater is more common. This type of wastewater contains a large amount of organic pollutants, with high toxicity, high concentration, high chemical oxygen demand, and poor biodegradability. It also contains a large amount of salt and acid-base substances, which are extremely harmful to water bodies and human health. Once organic wastewater is discharged into clean water bodies in nature, it will cause eutrophication of water quality, leading to foul odor, darkening of color, and serious deterioration of water quality. Therefore, it is necessary to carry out treatment. Below, Haipu will provide you with detailed information on organic wastewater treatment solutions, hoping to be helpful to you.

The main characteristics of pharmaceutical wastewater quality are as follows:

① There are multiple drainage points, and high and low concentration wastewater are discharged separately, which is conducive to the separation of clean water and sewage;

② Intermittent discharge of high concentration wastewater requires large collection and regulation devices;

③ High concentration of pollutants;

④ Low carbon to nitrogen ratio is not conducive to improving the load and efficiency of wastewater biological treatment

⑤ High nitrogen content affects COD removal;

⑥ The concentration of sulfates is generally high, which poses difficulties for anaerobic treatment of wastewater;

⑦ Wastewater contains substances that are difficult for microorganisms to degrade, and even have inhibitory effects on microorganisms;

⑧ Water generally has a higher chromaticity.

Antibiotic wastewater has high chromaticity, contains various difficult to degrade and biologically toxic substances, and the residual antibiotics in the wastewater can have potential environmental impacts. The production wastewater of traditional Chinese patent medicines and simple preparations contains a large number of polycyclic aromatic hydrocarbons, and the quality and quantity of the wastewater change greatly. The composition of synthetic drug production wastewater is complex, with high concentrations of organic pollutants and a large amount of toxic and harmful substances, which have a significant inhibitory effect on biological activity and are difficult to treat. The washing water and flushing wastewater in the production process of various preparations have significantly reduced concentrations of toxic and harmful organic compounds compared to other wastewater in the pharmaceutical process, with lower toxicity and ease of treatment. They can be treated together with other production wastewater.

Untreated or untreated pharmaceutical wastewater that does not meet discharge standards and enters the environment directly can cause serious harm. The content of recalcitrant organic compounds in pharmaceutical wastewater is high, and most of them have strong toxicity and "three causative" effects. After these recalcitrant pollutants are discharged into the water, they remain in the water for a long time and accumulate and enrich through the food chain, ultimately entering the human body and causing toxicity. When the organic matter content is too high and the rate of oxygen consumption by biological oxidation and decomposition exceeds the rate of reoxygenation, it will cause oxygen deficiency in the water, resulting in the death of aerobic aquatic organisms in the water. Anaerobic microorganisms will digest and produce substances such as methane and hydrogen sulfide, further inhibiting aquatic organisms and making the water odorous. In addition, pharmaceuticals and their synthetic intermediates often have certain bactericidal or bacteriostatic effects, affecting the metabolism of bacteria, algae and other microorganisms in water bodies, and ultimately disrupting the balance of the entire ecosystem.

The difficulty in treating pharmaceutical wastewater lies in the fact that certain components in the wastewater may inhibit the growth of microorganisms, further reducing the biodegradability of the wastewater and causing the effluent to not meet discharge standards. Therefore, improving biodegradability is the primary issue faced in the treatment of pharmaceutical wastewater. At present, the treatment methods for pharmaceutical wastewater mainly include physical and chemical methods, chemical methods, biochemical methods, and combined treatment processes.

Physical and chemical methods can be used as pretreatment methods to improve the biodegradability of wastewater, and can also be used as advanced treatment methods to ensure that the effluent meets discharge standards. The main physical and chemical treatment methods include coagulation, adsorption, air flotation, ion exchange, and membrane separation.

Chemical method is a traditional method for wastewater treatment, currently commonly used methods include oxidation, electrolysis, and advanced oxidation.

In the process of pharmaceutical wastewater treatment using biochemical methods, the use of aerobic or anaerobic biological treatment methods alone often cannot achieve the expected treatment effect. Therefore, a combination of multiple methods is commonly used to achieve discharge standards.

The special adsorption material for adsorption method is used to treat the wastewater, and the color of the adsorbed water is significantly reduced.

High boiling point organic matter is efficiently removed, and the distilled salt in the effluent is white

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. Through years of independent research and development, we have achieved international leading levels in ion exchange technology, adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products, and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

The application cases of Haipu nano adsorbent technology are as follows:

2. Customer demand for pharmaceutical wastewater treatment industry:

A certain pharmaceutical company mainly produces and operates pharmaceutical raw materials, chemical intermediates, and veterinary drugs. During the production process of the enterprise, high salt wastewater, acid adjusted mother liquor, and 104 types of wastewater are generated. The mixed water sample of the three types of wastewater after salt evaporation treatment has a darker color, which is not conducive to the stable production of the enterprise.

According to the production requirements of the enterprise and combined with the characteristics of the high salt wastewater, our company's developed special adsorption material for high salt wastewater is used to adsorb and treat the wastewater. The color of the adsorbed effluent is significantly reduced, high boiling point organic matter is efficiently removed, and the distilled salt in the effluent is white, which can meet the customer's requirements. Based on this, this technical solution is issued for reference by the enterprise.

3. Introduction to Haipu customized process:

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

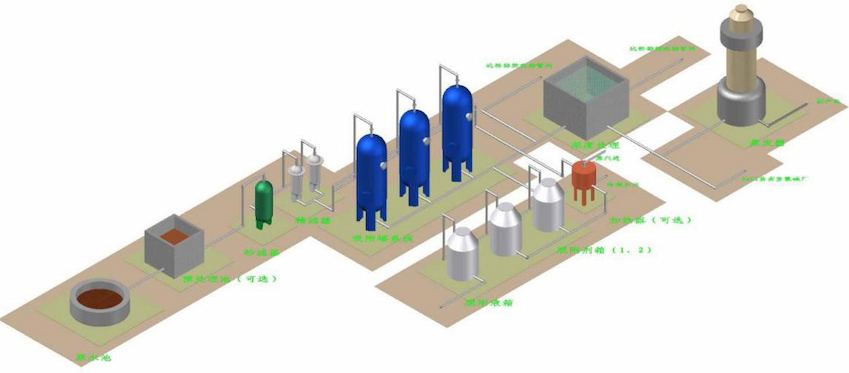

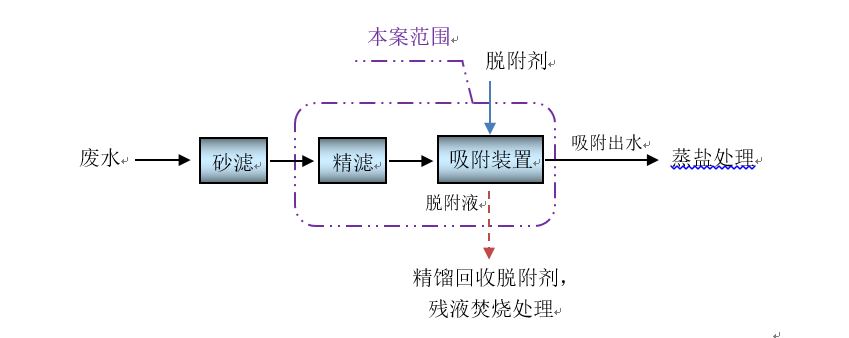

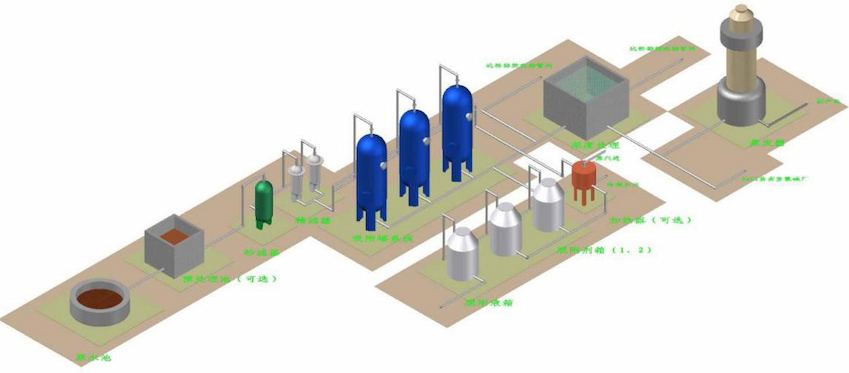

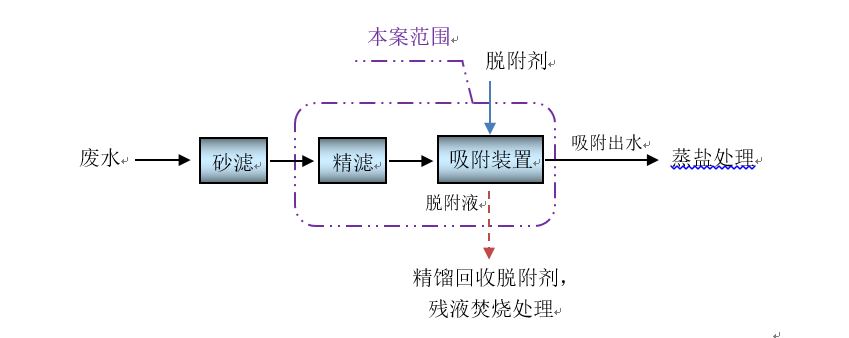

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to be regenerated. This process is continuously repeated. The conventional process of treating wastewater by adsorption method is shown in the following figure.

Conventional process diagram for adsorption treatment of wastewater

When using Haipu's adsorption process to treat pharmaceutical wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb the organic matter in the wastewater on the surface of the material, and discharge the water continuously to meet the standard. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The process flow of COD removal wastewater adsorption treatment is shown in the following figure.

Process flow of pharmaceutical wastewater adsorption treatment

4. The treatment effect of pharmaceutical wastewater process: The adsorption process is used to treat manufacturing wastewater, which can effectively remove the chromaticity in the wastewater and achieve the goal of qualified discharge. The specific treatment data is shown in the table below:

Table 2-1 Adsorption inlet and outlet water data

| Indicator | Chroma | Steamed salt |

| Absorb incoming water | Brown | Grey |

| Adsorbed water 1 | Canary yellow | White |

| Adsorbed water 2 | Canary yellow | White |

| Adsorbed water 3 | Canary yellow | White |

Figure Appearance of raw water (left) and effluent (right)

5. Case Introduction: A 100t/d COD containing wastewater water reuse project of a printing and dyeing enterprise in Jiangsu Province:

The company uses our adsorption process to treat various pharmaceutical wastewater generated during its production process, and the treated wastewater can be directly discharged to reduce the environmental pressure on the enterprise.

On site application of adsorption tower

CN

CN