1. Overview of Electroplating Wastewater

Electroplating wastewater refers to various types of wastewater discharged during the electroplating production process, including pickling wastewater, rinsing wastewater, passivation wastewater, wastewater from scrubbing floors and plates, and wastewater caused by "leakage" due to poor operation or management. The water quality and quantity of electroplating wastewater are related to the process conditions, production load, operation management, and water use methods of electroplating production.

The common characteristics of electroplating wastewater are complex water quality and difficult to control composition. It contains heavy metal ions such as chromium, cadmium, nickel, copper, zinc, gold, silver, and cyanide, which are highly toxic and cannot be degraded by simple biochemical methods. Some pollutants are highly toxic substances that cause cancer and mutations, and the physical and chemical treatment process is complex and the treatment cost is high. It is recognized as a high difficulty wastewater treatment in the industry.

2. Haipu customized zero row process

In order to achieve zero discharge of this type of electroplating wastewater, the commonly used zero discharge technology is to adjust and precipitate heavy metal wastewater, and then treat the effluent through a membrane system. The clean water is reused, and the concentrated water is sent to the evaporation system for desalination. Specifically, after pre adjusting the pH of the electroplating wastewater, appropriate coagulants and coagulants are selected for dosing and precipitation. The precipitate is treated as hazardous waste, and the supernatant enters the membrane system for treatment. The clear water generated by the membrane system can be directly reused in the production line, while the concentrated solution needs to be further evaporated and concentrated in the evaporation device. After the concentrated crystallization process of evaporation and condensation, it is separated into desalinated water and concentrated crystal slurry waste liquid. Salt and some organic matter can be crystallized and separated as solid waste for treatment. Desalinated water can be returned to the production system to replace softened water for utilization. However, in practical applications, on the one hand, due to the high organic content in electroplating wastewater, membrane system blockage often occurs. On the other hand, the heavy metal content in the wastewater after adjustment and sedimentation did not meet the standard, and the salt content after steaming was determined as hazardous waste, resulting in high treatment costs and causing difficulties for the stable operation of the enterprise.

The electroplating wastewater combination process developed by Jiangsu Haipu Functional Materials Co., Ltd. is used for adsorption treatment of wastewater after regulating sedimentation. The organic matter and heavy metal content in the effluent after adsorption treatment are significantly reduced, greatly improving the stability and economy of subsequent membrane and evaporation systems. The adsorbent material is desorbed and regenerated through an eluent, and the desorbed organic matter and heavy metals can be returned to the front-end sedimentation or utilized. On the one hand, this process reduces the processing load of the membrane system and extends its service life. On the other hand, it converts the evaporated salt from hazardous waste to solid waste, providing an effective solution for zero discharge of electroplating wastewater.

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has achieved international leading levels in ion exchange technology and adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

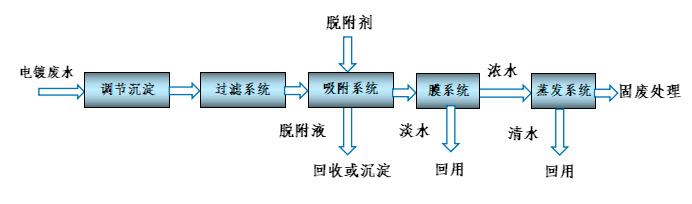

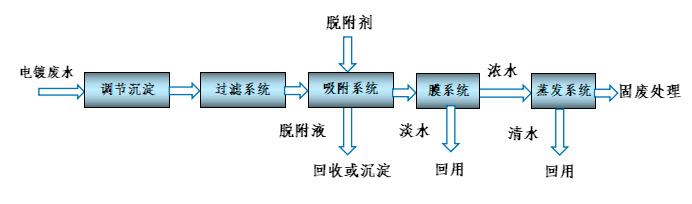

When using Haipu's customized process to treat electroplating wastewater, chemicals are first added to convert heavy metal components into precipitates, then suspended particulate matter is filtered and removed, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb organic matter and heavy metals in the wastewater on the surface of the material, significantly reducing the concentration of organic matter and heavy metals in the effluent. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The zero discharge process of electroplating wastewater is shown in the following figure:

Figure 1 Zero discharge process of electroplating wastewater

3. Case Introduction

This newly built zero discharge treatment facility for electroplating wastewater has a total designed wastewater treatment capacity of 40m³/h. The wastewater is from electroplating cleaning in the factory and contains high levels of organic matter and nickel. Haipu has customized a zero discharge process design for the wastewater, and the wastewater design indicators are shown in the table below.

Table 1 Wastewater Design Parameters Table

| Indicator | Water volume (m³/h) | COD(mg/L) | Nickel (mg/L) | Zinc (mg/L) |

| Device water inlet | 40 | 1000 | 60 | 100 |

| Device effluent | 40 | <30 | <0.1 | Not detected |

Figure 2 Appearance of raw water (left) and effluent (right)

Haipu's customized electroplating wastewater zero discharge process can remove organic matter and heavy metals from electroplating wastewater, reduce the color of the effluent, lower the production and operation costs of the enterprise, and provide guarantees for stable production on site for customers.

4. The advantages of zero emission technology

Deeply removing organic matter from wastewater, reducing heavy metals and chromaticity in the effluent, can ensure that the effluent is treated as solid waste and improve the stability of the subsequent evaporation system.

Using specially modified adsorption materials, with large adsorption capacity, low equipment investment, and low operating costs.

The process flow is simple and can achieve full automation operation, making operation and maintenance convenient.

It can be arranged in multiple layers, with a small footprint and a short installation cycle.

CN

CN