Have you ever wondered how industries purify water, extract metals, or even develop life-saving drugs? The unsung hero behind these processes is ion exchange resin.

Ion exchange resins are polymer beads that swap unwanted ions in liquids for preferred ones. They're essential in water treatment, mining, and pharmaceuticals - removing contaminants while retaining valuable substances like lithium or medicinal compounds.

These tiny beads power critical industrial processes worldwide. Let's examine what makes them so effective across industries from lithium mining to hospital water systems.

What is the ion exchange resin?

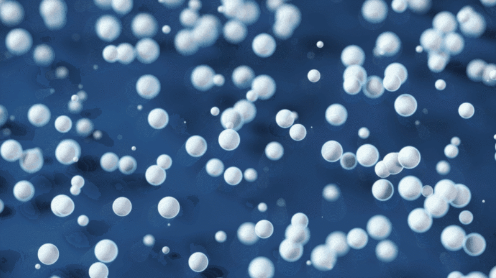

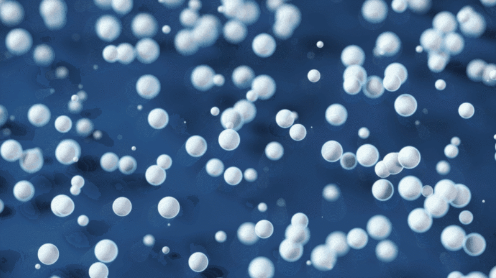

Picture thousands of tiny beads working like molecular trading posts - that's ion exchange resin in action.

Ion exchange resins are porous polymer beads (0.3-1.2 mm diameter) containing active sites that swap target ions. They function like chemical sponges, trapping unwanted ions while releasing beneficial ones into solutions.

Ion exchange resins consist of a structural matrix (typically polystyrene or acrylic) with attached functional groups that perform the ion exchange. These functional groups determine the resin's properties - sulfonic acid groups create strong acid cation exchangers, while quaternary ammonium groups form strong base anion exchangers. The matrix is cross-linked with agents like divinylbenzene for stability.

At Haipu, we've developed resins specifically engineered for specialized industrial applications. Our lithium extraction resins can operate in extreme brine environments while maintaining selectivity for lithium ions. Pharmaceutical-grade resins undergo rigorous purification to meet stringent FDA and EP standards for medical applications.

What is the principle of ion exchange resin?

The magic happens at atomic level - where resins play matchmaker between ions.

Ion exchange works through electrostatic attraction - functional groups on resin beads selectively attract oppositely charged ions from solutions, swapping them for less-wanted ions previously attached to the resin.

The ion exchange process occurs in several distinct stages. First, target ions diffuse through the liquid to reach the resin surface - this happens faster in warm, dilute solutions. Then the actual exchange occurs as ions cross the resin boundary, with preference given to ions that have higher charge density or better affinity for the functional groups. Finally, spent resins can be regenerated using brine or acid solutions to restore their exchange capacity.

Haipu's advanced resin formulations demonstrate remarkable performance characteristics. Our salt lake lithium extraction resins show 98% selectivity for lithium over other cations like sodium or potassium. They withstand hundreds of regeneration cycles while maintaining stability across extreme pH ranges from 1 to 14, making them ideal for harsh industrial environments.

Is resin toxic to the body?

Safety first - should we worry about these chemical workhorses?

Properly manufactured ion exchange resins are non-toxic when intact. However, degraded resins may release trace monomers. Food/pharma applications use ultra-pure, FDA-compliant resins with thorough pre-treatment protocols.

At Haipu, we implement comprehensive safety measures for all our resin products. Pharmaceutical-grade resins undergo extensive testing to meet international standards including USP <661> for extractables, EP 7.0 for heavy metal content, and FDA 21 CFR for monomer residuals. Each batch is analyzed using advanced techniques like HPLC, ICP-MS and GC-MS to ensure purity standards are met.

Our medical-grade resins go through rigorous pre-treatment to remove any manufacturing residues. Stability testing simulates years of use to guarantee performance consistency. Continuous leachables monitoring ensures no harmful substances are released during application. These resins are trusted for critical healthcare applications including hemodialysis water purification, intravenous solution preparation, and vaccine production.

How to choose ion exchange resin?

Picking the right resin is like choosing a molecular toolkit - match the job to the beads.

Select resins based on: target ions, flow rate needs, temperature/pH conditions, and regeneration requirements. Industrial applications demand durability, while pharmaceutical uses prioritize purity certifications.

The selection process begins with understanding the specific application requirements. For water treatment, we typically recommend resins with capacities between 1.8-2.2 eq/L and stability in pH 2-10. Lithium mining operations need specialized resins with Li+ capacities exceeding 2.5 eq/L and tolerance for extreme pH ranges. Pharmaceutical applications demand smaller bead sizes (0.4-0.7 mm) and rigorous certifications.

Haipu employs a systematic approach to resin selection. We begin with comprehensive bench testing to simulate actual operating conditions. Promising candidates then undergo pilot trials to validate performance in real-world scenarios. Finally, we conduct full lifecycle analysis to calculate the total cost of ownership, considering factors like regeneration frequency, expected lifespan, and maintenance requirements. This approach recently helped a Chilean lithium plant achieve 30% higher yields compared to standard resin products.

About the Author

Dr. Elena Rodríguez

Materials Science Director, Haipu Functional Materials

With 15 years in separation technologies, Dr. Rodríguez leads Haipu's R&D in ion exchange applications from lithium extraction to pharmaceutical purification. Her work has produced 12 patents in functional material design.

References

International Atomic Energy Agency. (2021). Application of Ion Exchange Materials in the Environmental Cleanup. IAEA-TECDOC-1974. www.iaea.org

Helfferich, F. (1962). Ion Exchange. McGraw-Hill. ISBN 978-0486687841.

U.S. Pharmacopeia. (2023). <661> Plastic Materials and Their Additives Used in Manufacturing. USP-NF.

Lithium Recovery Commission. (2022). Best Practices in Lithium Brine Processing. LRC Technical Report #22-045.

World Health Organization. (2020). Guidelines for Drinking-water Quality: Fourth Edition. WHO Press. [ISBN 9789241549950]

CN

CN