Preface

With the development of dye production and printing and dyeing industry, the discharge of dye industry wastewater has also increased sharply. According to surveys, about 160 million cubic meters of dye wastewater are discharged into the water environment in China every year. Moreover, dye wastewater has the characteristics of high chromaticity, high organic pollutant content, complex composition, significant water quality changes and biological toxicity, as well as difficulty in biochemical degradation, and is developing towards anti photolysis and anti-oxidation, which further increases the difficulty of treating dye wastewater. Printing and dyeing wastewater contains a large amount of organic pollutants, which will consume dissolved oxygen when discharged into water bodies, disrupt the water ecological balance, and endanger the survival of fish and other aquatic organisms. Organic matter that sinks to the bottom of the water can produce harmful gases such as hydrogen sulfide through anaerobic decomposition, deteriorating the environment. Due to the above reasons, it has become one of the difficult industrial wastewater to treat both domestically and internationally. China has listed the treatment of dye wastewater as a key focus of environmental protection work.

3,3 '- Dichlorobenzidine (DCB) is an important intermediate for pigments. Among the 130 yellow pigment varieties listed in the "World Dye Varieties" based on the 1999 version of ColourIndex, there are 22 yellow pigments with DCB as the diazo component, accounting for 16.9%. The obtained pigment has pure and bright color, good alkali resistance and heat resistance, and is an irreplaceable variety in the pigment industry. The production of pigments using DCB as raw material accounts for 25% to 30% of organic pigments, with a production of about 60000 tons, and is growing at a rate of about 4% per year.

Among them, 3,3 '- dichlorodiphenylamine hydrochloride (DCB) dye wastewater is difficult to degrade, and the wastewater quality is shown in Table 1.

Table 1 Water Quality Parameters of Dye Production Wastewater

| Project | Range | Average value |

| COD/(mg·L-1) | 11600~33686 | 224820 |

|

| BOD5/(mg·L-1) | 800~900 | 885 |

|

| NaOH/% | 7~9 | 8 |

|

| NH4+-N/(mg·L-1) | 1148~1347 | 1247.9 |

|

| TN/(mg·L-1) | 1236~1540 | 1388 |

|

| SS/(mg·L-1) | 1600~1900 | 1700 |

|

| pH | 13.75~13.98 | 13.9 |

|

| Chromaticity/Doubling | — | 20000 |

|

| Aniline/(mg·L-1) | 220~320 | 270 |

|

| Conductivity/(μs·cm-1) | 12114~13840 | 12900 |

|

1. Common dye industry wastewater treatment technologies

There are currently multiple physical, chemical, and biological methods that can be used for decolorization and degradation of dye wastewater. The commonly used methods for industrial dye wastewater treatment both domestically and internationally include biological treatment, chemical flocculation, chemical oxidation, adsorption, and electrochemical methods. Other technologies such as membrane separation and irradiation are also being promoted and applied. In specific urban sewers and sewage treatment, wastewater is first pretreated in factories to meet urban sewer discharge standards before being centrally treated. Pre treatment and discharge of wastewater can improve the quality of sewage, reduce the treatment load of urban sewage plants, and facilitate the adoption of different pretreatment methods according to different wastewater quality. In the final treatment of printing and dyeing wastewater, the removal of organic matter is generally mainly carried out by biological methods. For printing and dyeing wastewater that is difficult to biodegrade, anaerobic (hydrolysis) aerobic combined treatment is more suitable. For printing and dyeing wastewater that is easy to biodegrade, a stage of biological treatment can be used. The removal of chromaticity is generally carried out by physical and chemical methods. For large-scale and high-level factories, processes such as electrolysis, chemical flocculation, and ozone oxidation can be used. For small-scale factories, slag filtration can be used. The following is a summary of specific printing and dyeing wastewater treatment processes at home and abroad.

1.1 Biological treatment method

The biological treatment method mainly separates and degrades chromogenic substances in wastewater through the flocculation, adsorption, and biodegradation of biological bacteria. The coagulation and adsorption of organisms belong to physical processes and cannot cause chemical changes in the structure of dye molecules. The degradation of organisms uses microbial enzymes to oxidize or reduce dye molecules, destroy their chromophores and unsaturated bonds, and through a series of oxidation, reduction, hydrolysis, and chemical processes, ultimately degrade dyes into simple inorganic substances or transform them into various nutrients or protoplasts. Most of the organic matter in wastewater can be biodegraded, even if it is a benzene ring structure, it can be decomposed by Nocardia and Streptococcus. Under the action of coenzyme HSCOA, the benzene ring is cleaved, decomposed into organic acids, and finally oxidized into CO2 and H2O. Therefore, since the last century, biological treatment methods have been widely used in dye wastewater treatment due to their low operating costs and economic applicability. More than 80% of dye wastewater worldwide is still mainly treated by biological methods, with aerobic biological treatment accounting for the vast majority.

Biological treatment methods can be divided into aerobic biological treatment methods and anaerobic biological treatment methods. Although aerobic treatment method has a high removal rate of BOD, with a removal rate of up to 80%, and the operating cost is relatively low. But the degradation effect on complex macromolecular substances is poor, only about 50%. Therefore, the removal rate of chromaticity and recalcitrant organic matter in dye wastewater is often not ideal, especially with the widespread application of chemical slurries such as PVA, surfactants, and fabric alkali reduction technology. The CODcr of dye wastewater can reach 3000mg · L -1, and its biodegradability is significantly reduced. BOD/CODcr is generally less than 0.2, and it is difficult to meet the standard for effluent using only aerobic biological treatment. Compared to aerobic treatment, anaerobic biological treatment can significantly degrade complex macromolecular substances under certain conditions and is a promising industrial wastewater treatment method. However, anaerobic treatment of industrial wastewater is often accompanied by a foul odor, and the use of anaerobic treatment alone to treat dye wastewater is not ideal, making it difficult to meet discharge standards. Therefore, after the current biological treatment equipment for dye industry wastewater, physical and chemical treatment (coagulation sedimentation or air flotation) devices are usually connected in series for further treatment. In the subsequent processing. Based on the limitations of the above-mentioned biological treatment methods and the current development of dyes towards anti photolysis and anti biological oxidation, exploring the optimization combination of biological treatment processes and screening degradation bacteria with strong degradation ability and efficient flocculation activity has become a hot research topic, and has achieved gratifying results.

1.2 Flocculation method

Flocculation method is a method of adding certain substances to wastewater, and through physical or chemical actions, causing pollutants that were originally dissolved in wastewater or in a fine suspended state, not easily settled (or air floated), and filtered to aggregate into larger particles for separation from water, thereby separating and removing chromophores enriched in wastewater. The coagulation methods mainly include coagulation precipitation method and coagulation air flotation method, and the coagulants used can be divided into two categories: inorganic and organic. Inorganic coagulants are mostly aluminum and iron salts, and commonly used coagulants include lime (Ca(OH)2), aluminum sulfate (Al2(SO4)3 · 14H2O), ferric chloride (FeCl3), ferrous sulfate (FeSO4), iron sulfate (Fe2(SO4)3), as well as inorganic polymer polymers such as polyaluminum chloride, polyferric sulfate (PFS), polyferric sulfate, etc. Inorganic polymer coagulants have the advantages of low corrosiveness, wide pH range, good coagulation and sedimentation performance, good dehydration performance, and good wastewater treatment effect. Organic coagulants refer to natural or artificially synthesized organic polymer substances that can exert flocculation effects. According to the characteristics of dissociable functional groups, they can be divided into anionic types (such as -COOH, -SO3H, -OS3H, etc.), cationic types (such as - NH3OH, - NH2OH, - CONH3OH, etc.), amphoteric types (containing both types of functional groups), and nonionic types (non electrolytes that cannot be ionized). The commonly used organic polymer flocculants in dye wastewater include CG-A, DC-491, 611 cationic polymer flocculants, mPAM (methylene polypropylene amide), etc. Compared with inorganic flocculants, it has the advantages of good decolorization effect, low dosage, wide pH range, and small sludge volume. In recent years, the use of organic polymer coagulants has been increasing abroad, and there is a trend to replace inorganic coagulants. However, the high price of organic coagulants affects their widespread application. Flocculation method is often used as a separate treatment or combined with biochemical treatment for pretreatment.

The flocculation method has a high decolorization efficiency for hydrophobic dyes, with a chromaticity removal rate of over 92%. However, its decolorization effect for hydrophilic dyes is low, with a low CODcr removal rate. Therefore, flocculation method is often combined with other treatment methods (such as biochemical treatment, filtration, etc.), and the treated effluent has a CODcr removal rate of 70% to 80%, a BOD5 removal rate of 90% to 96%, and a chromaticity removal rate of over 70%. Flocculation is considered one of the most effective and economical decolorization technologies, even more economical than biological treatment methods. It has the advantages of low engineering investment, small footprint, large processing capacity, and high decolorization efficiency for hydrophobic dyes. However, the flocculation method has disadvantages such as poor decolorization effect on hydrophilic dyes, low CODcr removal rate, long treatment time, generation of a large amount of sludge, and difficulty in dewatering treatment. These are the main reasons that affect the widespread application of this method in engineering practice. Therefore, the development of new multifunctional and efficient flocculants and optimization of application processes are currently the focus of this method research.

1.3 Chemical oxidation method

Chemical oxidation is one of the main methods for decolorization and degradation of dye wastewater, which utilizes oxidation to destroy the conjugated system or chromophore groups of dyes. In addition to conventional chlorine oxidation methods, domestic and foreign research focuses mainly on ozone oxidation, hydrogen peroxide oxidation, electrolytic oxidation, and photooxidation. However, due to the fact that the chlorine oxidation method is prone to producing small molecules, more dangerous organic halides such as trichloromethane, which can cause animal tumors and damage the nervous system while decolorizing, it is now rarely used; Although hydrogen peroxide and photocatalytic methods have the advantages of high efficiency and no secondary pollution, they are still limited by treatment costs and energy consumption, and there is still a certain distance from industrial application. Ozone is a good decolorizing and oxidizing agent, with high decolorization rates for water-soluble dye wastewater such as reactive, direct, cationic, and acidic dyes; It also has a good decolorization effect on dispersed dyes; However, the decolorization effect is poor for other reduction, sulfurization, and coatings that exist in a suspended state in wastewater. Ozone oxidation can also be combined with other treatment technologies for application. If FeSO4, Fe2 (SO4)3, and FeCl3 are used, and then treated with ozone after coagulation, the decolorization treatment can be improved; Ozone combined with ultraviolet radiation or simultaneous ionizing radiation can also improve oxidation efficiency. Due to its wide adaptability to dye varieties and high decolorization efficiency, ozone oxidation, as well as the reduction products of O3 in wastewater and excess O3, can quickly decompose into O2 in solution and air without causing secondary pollution to the environment. Therefore, O3 decolorization technology has certain industrial application prospects. At present, the main disadvantage of ozone oxidation is relatively high operating costs. Therefore, the chemical oxidation method currently used for industrial wastewater treatment both domestically and internationally is mainly ozone oxidation.

1.4 Adsorption method

One of the main advantages of adsorption decolorization is that the dye can be removed from water through adsorption, and the adsorption process preserves the structure of the dye. At present, the adsorbents mainly used for dye industry wastewater treatment at home and abroad include activated carbon, silicone polymers, macroporous resins and other materials with large specific surface area as adsorbents, which have good effects on removing dye chromaticity. However, due to relatively high costs, they have not been widely promoted and applied; Low cost materials such as kaolin and industrial slag can also have a certain decolorization effect on dye wastewater as adsorbents, but it is still in the experimental exploration stage. The current adsorption method for industrialized treatment of dye wastewater is mainly activated carbon adsorption. Activated carbon, as an excellent adsorbent, has been widely used and remains the best adsorbent for colored wastewater to this day. The activated carbon adsorption method is very effective in removing water-soluble organic matter, and has good adsorption performance for water-soluble dyes such as cationic dyes, direct dyes, acidic dyes, and reactive dyes. The decolorization rate is above 97%, and the CODcr removal rate is 63% to 95%. However, activated carbon adsorption shows significant limitations in the treatment of high concentration and hydrophobic dye wastewater, and due to the high cost of using activated carbon, the unit wastewater treatment cost is relatively high. Therefore, activated carbon adsorption method is often used in combination with other methods, mainly for the pretreatment or deep treatment of wastewater. Therefore, the current research and development of adsorbents with wide applicability, high adsorption efficiency, easy regeneration, stable performance, and low processing costs is an important direction for the future development of this technology method.

Jiangsu Haipu Functional Materials Co., Ltd. is located in the beautiful Suzhou Industrial Park and is a high-tech enterprise dedicated to the research and development of high-performance adsorbents, catalysts, and process applications. Jiangsu Haipu is committed to providing internationally leading products, technologies, and overall solutions for industries such as environmental protection, resource regeneration, new energy, chemical and pharmaceutical, food, and printing and dyeing.

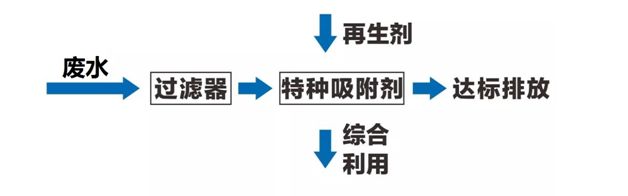

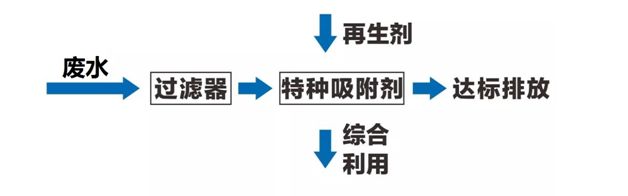

In response to the properties and treatment requirements of wastewater from food, printing and dyeing, coking, and other industries, a biochemical tail water upgrading and decolorization resin has been developed, which has the advantages of fast adsorption speed, high capacity, and easy regeneration. It can achieve deep COD removal and decolorization treatment of large amounts of wastewater, providing guarantee for the reuse of water resources. This technology has a large material adsorption capacity, low operating cost, easy regeneration, and long service life; The equipment has technical advantages such as low operating costs, low maintenance costs, and simple operation. It is widely used in the removal of COD and decolorization treatment of wastewater generated in printing and dyeing, coking, food and other processes. The process flow is as follows:

Figure 1 Process Flow Diagram

With advanced products and technological advantages, Jiangsu Haipu Company has gradually gained support and recognition from customers in various industries and governments at all levels. Jiangsu Haipu's integrated resource management solutions for wastewater, waste gas, and waste acid have been established in dozens of demonstration applications in leading enterprises in petrochemical, agrochemical, pharmaceutical, coal chemical, electroplating, printing and dyeing industries.

1.5 Electrochemical method

Electrochemical method is a method of decolorizing and degrading dyes by using the redox agents generated by electrodes to destroy the molecular structure of dyes. Electrochemical methods are mainly divided into electrolysis, electrical flotation, and microbattery methods. Research has shown that electrochemical methods are effective methods for treating dye wastewater in terms of chromaticity, CODcr, BOD, and TSS. The electrolysis method uses graphite, titanium plates, etc. as electrode plates, and NaCl, Na2SO4, or existing salts in water as conductive media to electrolyze dye wastewater. The anode produces O2 or Cl2, and the cathode produces H2. The oxidation and reduction of newly generated oxygen or NaClO during the electrolysis process destroy the molecular structure of the dye and decolorize it; The electrical flotation method uses Fe and Al as anodes, and generates Fe2+and Al3+hydrolysis products through electrode reactions to form flocs. The dye molecules are decolorized through oxidation-reduction and adsorption, and the flocs float up due to the H2 generated by the cathode; The micro battery method uses cast iron shavings as filter material, immerses or passes dye wastewater, and utilizes the potential difference between Fe and wastewater to generate electrode effect. The electrode reaction produces a new ecology of H with high chemical activity, which can undergo oxidation-reduction reactions with various components in dye wastewater and destroy the color structure of the dye.

Electrochemical treatment of dye wastewater generally does not require the addition of chemicals, with simple post-treatment, small footprint, and convenient management, and is known as a clean treatment method. Except for cationic dyes, the decolorization rate of other dye wastewater by electrochemical methods is above 90%. However, in actual operation, the high unit power consumption and electrode material usage limit its development and widespread application. Therefore, the development of high-performance new electrode materials and efficient electrochemical reaction processes is the key to the practical application of this technology, and it is also an important direction for improving electrochemical technology at present.

2. Research progress on new technologies for dye wastewater treatment

Due to the current difficulty in meeting the technical and economic needs of dye companies in practical dye wastewater treatment technologies. Therefore, many environmental technology workers are committed to the research and development of new dye wastewater treatment technologies. In recent years, research on new technologies for dye wastewater treatment has been active, including supercritical water oxidation technology, high-temperature deep oxidation technology, low-temperature plasma chemistry technology, ultrasonic technology, extraction technology, photocatalytic technology, and Fenton oxidation technology.

2.1 Supercritical water oxidation technology

Supercritical water oxidation (SCWO) refers to the oxidation of organic compounds in water under conditions where the temperature and pressure are higher than the critical temperature (374 ℃) and critical pressure (22.1Mpa) of water. Due to the disappearance of the interface between supercritical water, gas, and liquid phases, the density difference between saturated water and dry saturated vapor will be zero, resulting in a homogeneous system. At this unique state point (critical point), the oxidation reaction rate of organic matter in water is extremely fast. Almost all organic matter in water undergoes complete oxidation and decomposition with oxygen or oxygen in the air within seconds to minutes, with a decomposition rate of up to 99.99%. Model et al. conducted SCWO experiments on organic wastewater with an organic carbon content of 27.33g · L -1. At a temperature of t=550 ℃, the destruction rates of organic chlorine and organic carbon were 99.99% and 99.97%, respectively, within 1 minute. Compared with other traditional methods, supercritical water oxidation has the advantages of high efficiency, high removal rate of toxic substances, thorough oxidation, simple reactor structure, and large processing capacity. However, there are still technical issues that need to be addressed for industrial application, such as harsh reaction conditions (high temperature, high pressure), high material requirements for reaction equipment, and blockage of reactors and pipelines by inorganic salts.

2.2 Low temperature plasma chemistry

Plasma is a non condensed system generated by partial ionization of gas (vapor) under specific conditions. The temperature of heavy particles such as ions, free radicals, neutral atoms, or molecules in the system is close to or slightly higher than room temperature, so these plasmas are called low-temperature plasmas. Low temperature plasma contains active substances with high enough energy to excite, ionize, or break bonds in reactant molecules.

2.3 Ultrasonic technology

Ultrasonic technology refers to the wastewater treatment technology that utilizes the cavitation effect generated by ultrasonic radiation to collapse and release energy in a very short period of time, forming a "microreactor" with extreme physical and chemical conditions and high energy content, and causing water molecules to crack and form H2O2, · H, · OH, decomposing organic macromolecules dissolved in water into environmentally acceptable small molecule compounds. Ultrasonic treatment of wastewater is an effective new technology that can accelerate dye decolorization and mineralization rates.

2.4 Extraction Technology

Extraction technology is mainly a technology that purifies wastewater by complexing extractants with pollutant molecules, or by allowing pollutants in water to enter the extraction phase through a very thin membrane layer under the action of a carrier. The essence of using extraction technology to treat dye wastewater is to extract dye molecules from water using insoluble or poorly soluble solvents.

2.5 Photocatalytic degradation technology

Photocatalytic oxidation technology uses semiconductors as catalysts to generate highly oxidizing holes in the valence band of semiconductors under light conditions. These holes oxidize OH - and H2O molecules in water into highly oxidizing · OH radicals, which then oxidize recalcitrant organic compounds into CO2 and H2O. Common catalysts include inorganic reagents such as TiO2, H2O2, and Fe (C2O4) 3. Photocatalytic oxidation technology is an emerging technology that has emerged in recent years, with obvious characteristics such as energy saving, high efficiency, and thorough degradation of pollutants.

2.6 Fenton oxidation technology

Fenton oxidation technology is an advanced oxidation technology mainly based on H2O2, and the Fenton reagent is composed of Fe2+and H2O2. The hydroxyl radicals (· OH) generated by the reaction of Fe2+and H2O2 have strong oxidizing properties (second only to fluorine) and are non selective. They can oxidize and break the conjugated system structure of organic polymers, allowing persistent and difficult to degrade dye organic compounds to degrade into colorless organic small molecules for the purpose of decolorization. Moreover, Fenton oxidation technology has the advantages of simple operation process, easy availability of reactants, low cost, no need for complex equipment, and environmental friendliness. It has gradually been applied in wastewater treatment projects such as dyes, preservatives, phase reagents, pesticides, etc., and has great application prospects and great promotion value. However, based on existing research results, Fenton oxidation technology still has shortcomings such as the need to improve its oxidative degradation capacity, slow mineralization rate of pollutants, and iron ion content in the effluent; Improving the generation mechanism and reaction conditions of hydroxyl radicals (· OH) in Fenton reaction, and increasing the generation and utilization rate of hydroxyl radicals (· OH) will be an inevitable trend in the development of this technology.

3. Conclusion

Although using physical, chemical, and biochemical methods as basic treatment units to treat certain dye wastewater can achieve certain treatment effects. But so far, dye wastewater is still one of the industrial wastewater that is difficult to treat. It is necessary to consider not only the progressiveness of treatment technology, but also the feasibility of infrastructure investment and operating costs. Therefore, the main focus of dye wastewater treatment technology is on the following four aspects: efficiency, adaptability, economy, and cleanliness.

CN

CN