Electroplating products have a wide range of applications and are an indispensable part of China's socio-economic development. However, it is also one of the world’s three major polluting industries. According to incomplete statistics, electroplating production in China discharges 400 million tons of heavy metal-containing wastewater annually.

In addition to containing large amounts of toxic and hard-to-degrade heavy metal wastewater, electroplating wastewater also includes acidic and alkaline wastewater, oily wastewater, organic wastewater, and cyanide-containing wastewater.

Therefore, in recent years, government departments have been actively promoting the concept of centralized construction and pollution control in electroplating enterprises, with energy conservation, emission reduction, and heavy metal pollution prevention and control gradually penetrating electroplating parks.

However, some electroplating parks still face several prominent issues in wastewater treatment:

In the electroplating industry, in areas with high land development density, weakened environmental carrying capacity, and reduced environmental capacity, it is difficult for electroplating parks with simple wastewater treatment processes and facilities to meet the strict limits of the “National Electroplating Water Pollutant Discharge Standards.”

To control the total discharge of heavy metal pollutants in the electroplating industry, the state requires electroplating parks to control and gradually reduce pollutant discharge, improve water resource utilization, and achieve water reuse. Currently, electroplating parks in the Pearl River Delta region generally require a wastewater reuse rate of over 60%. Electroplating parks must invest heavily in building wastewater reuse systems and establish specialized operation teams for long-term operation.

The complexity of wastewater treatment processes and the variety of treatment equipment increase the operating costs of wastewater treatment in electroplating parks. To reduce production and operating costs, parks or enterprises may leave wastewater treatment equipment idle, reduce the amount of treatment chemicals, inadequately treat wastewater, or even illegally discharge or leak wastewater.

In addition to the above issues, electroplating parks also face problems such as unstable operation, outdated processes, chaotic management, and improper operation in wastewater treatment.

The root cause of these issues in electroplating wastewater treatment is the high concentration of waste liquids in electroplating workshops, which significantly impacts treatment costs, effectiveness, and reuse rates.

Traditional high-concentration waste liquids include: degreasing wastewater, cyanide-containing wastewater, chromium-containing wastewater, chemical nickel wastewater, nickel sulfate wastewater, and miscellaneous (acid copper, tin plating, zinc, stripping solution).

Upgraded high-concentration waste liquids include: chromic acid waste liquid, acid nickel waste liquid, alkaline waste liquid, heavy metal waste liquid, chemical nickel waste liquid, mixed waste acid, waste nitric acid, waste phosphoric acid, waste hydrofluoric acid, cyanide-containing waste liquid, complex waste liquid, and reverse osmosis membrane concentrate.

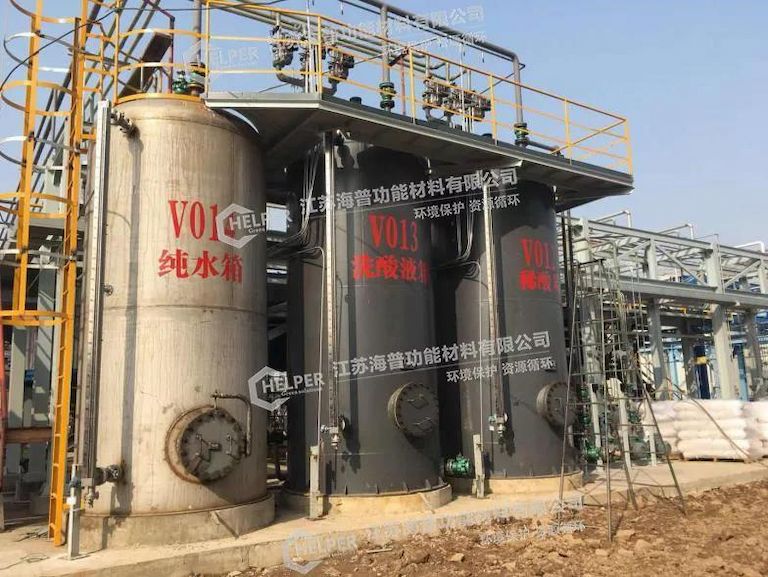

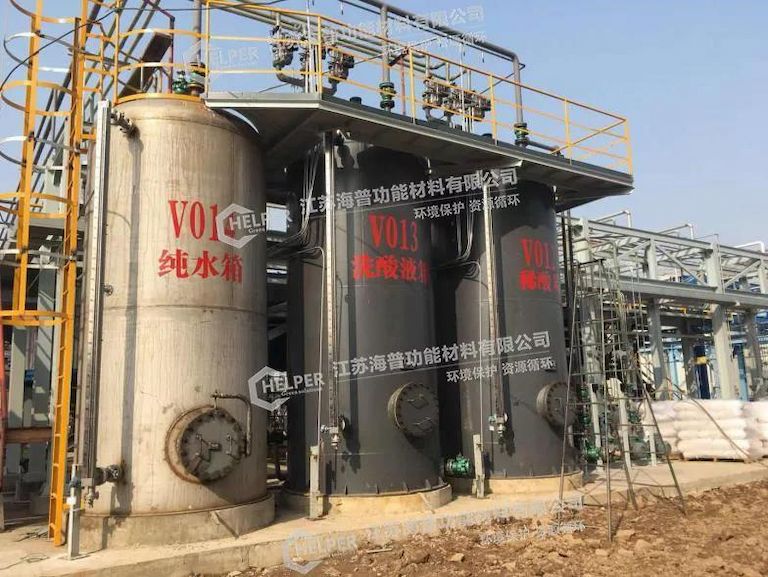

As a high-tech enterprise focused on the research and development of high-performance adsorbents, catalysts, and their process applications, Jiangsu Haipu Functional Materials Co., Ltd. provides specialized adsorption materials with extensive experience and technical expertise in electroplating wastewater treatment.

Case Studies

Electroplating Enterprise Wastewater Treatment Project

Deep Nickel Removal

A certain electroplating enterprise mainly undertakes electroplating processing services in the automotive, aviation, aerospace, and nuclear power fields. The terminal effluent nickel content of its 120t/h wastewater treatment facility could not consistently meet standards. Our company used nano-adsorption materials for deep nickel removal, reducing the effluent nickel content to less than 0.05mg/L, far below the enterprise’s discharge requirement (0.1mg/L), solving the problem of excessive nickel in the wastewater and promoting sustainable development.

| Inlet Concentration | Outlet Concentration | Removal Rate |

| ~2mg/L | 0.048mg/L | 97.60% |

| ~2mg/L | 0.039mg/L | 98.05% |

| ~2mg/L | 0.045mg/L | 97.75% |

Electroplating Enterprise Wastewater Treatment Project

Deep Chromium Removal

An electroplating processing enterprise serving the electronics and communications industry produces 200t/d of chromium-containing wastewater daily. Our designed process deeply removes chromium from the wastewater, achieving a chromium removal rate of over 90%, with effluent chromium content far below enterprise requirements and discharge standards.

| Raw Water Chromium Content | Treated Water Chromium Content | Removal Rate |

| 5.7mg/L | 0.275mg/L | 95.20% |

| 5.7mg/L | 0.306mg/L | 94.60% |

| 5.7mg/L | 0.279mg/L | 95.10% |

Electroplating Enterprise Wastewater Treatment Project

Zinc-Containing Wastewater

An electroplating industrial park produces 1062t of zinc-containing wastewater daily, with excessive zinc and nickel ions. Our designed process ensures that the effluent nickel and zinc meet discharge standards, with effluent nickel ions stabilized below 0.1mg/L and zinc ions below 1mg/L, solving the park’s wastewater treatment challenges.

| Raw Water Chromium Content | Treated Water Chromium Content | Removal Rate |

| 5.7mg/L | 0.275mg/L | 95.20% |

| 5.7mg/L | 0.306mg/L | 94.60% |

| 5.7mg/L | 0.279mg/L | 95.10% |

Electroplating Enterprise Wastewater Treatment Project

Anodizing Nickel-Containing Wastewater

An electroplating industrial park produces 2400t of anodizing wastewater daily, with excessive nickel ions. Our designed process deeply removes nickel from the wastewater, stabilizing effluent nickel below 0.1mg/L, meeting discharge requirements, and allowing direct entry into the intermediate water tank for further treatment.

| Inlet Nickel Content | Outlet Nickel Content | Removal Rate |

| 16mg/L | <0.1mg/L | >99.4% |

Electroplating Industrial Park Wastewater Treatment Project

Cyanide Copper Wastewater

Electroplating Industrial Park Wastewater Treatment Project

Cyanide Copper Wastewater

An electroplating industrial park produces 1125t of cyanide copper wastewater daily, with excessive copper and nickel ions. Our designed process, involving multiple stages of comprehensive treatment, stabilizes effluent nickel below 0.1mg/L and copper below 0.3mg/L, meeting enterprise requirements and allowing direct entry into the intermediate water tank for further treatment.

Electroplating Enterprise Wastewater Treatment Project

Phosphorus-Containing Wastewater

An electroplating enterprise engaged in metal surface treatment and heat treatment processing produces 200t of phosphorus-containing wastewater daily. Our designed process deeply removes phosphorus from the wastewater, stabilizing total phosphorus content below 1mg/L, meeting enterprise requirements, and allowing direct discharge, solving the enterprise’s wastewater treatment challenges.

| Raw Water Total Phosphorus Content | Treated Water Total Phosphorus Content | Removal Rate |

| 17mg/L | <1mg/L | >94.12% |

Electroplating Wastewater Treatment Project

Electroplating Industrial Park Fluoride-Containing Wastewater

An electroplating industrial park produces 300t of fluoride-containing wastewater daily, with a fluoride ion concentration of 14.2mg/L, exceeding discharge standards. Our designed process ensures that effluent fluoride ions meet discharge standards, providing an effective method for treating fluoride-containing wastewater in the park.

| Raw Water Fluoride Content | Treated Water Fluoride Content | Removal Rate |

| 14.2mg/L | <1mg/L | >93% |

Electroplating Enterprise Wastewater Treatment Project

Passivation Solution Iron Removal and Resource Recovery

An electroplating processing enterprise serving the electronics and communications industry produces 1000t of passivation solution wastewater daily, containing large amounts of iron, chromium, and zinc. Using our nano-adsorption materials, we deeply remove iron from the passivation solution, reducing effluent iron to below 0.5mg/L, while also removing some zinc. The treated passivation solution can be reused in production, significantly increasing the enterprise’s economic benefits.

CN

CN