Ammonia nitrogen wastewater mainly originates from industries such as fertilizers, coking, petrochemicals, pharmaceuticals, and food processing. Typically, biochemical treatment methods are used to reduce the ammonia nitrogen content in wastewater. However, with the rapid development and expansion of industries like fertilizers and petrochemicals, more and more high-ammonia nitrogen wastewater fails to meet biochemical treatment standards, becoming a significant constraint on industry development.

Ammonia nitrogen wastewater contains a large amount of ammonium ions and free ammonia. If discharged directly into water bodies without any treatment, it will cause eutrophication of the water, disrupting the entire biological growth environment.

Moreover, the toxicity of ammonia nitrogen far exceeds that of ammonium salts, and excessive levels can be toxic to aquatic life.

Especially under conditions with sufficient oxygen, ammonia nitrogen can be oxidized by microorganisms into nitrite nitrogen, which can then combine with proteins to form nitrosamines. If these enter the human body through aquatic organisms, they pose carcinogenic and teratogenic threats.

Current Status of Ammonia Nitrogen Wastewater Treatment

To eliminate the threats posed by ammonia nitrogen wastewater to the environment, aquatic life, and human health, reliable measures must be taken promptly. Common methods include air stripping, membrane technology, adsorption, chemical precipitation, and biological methods, to control the ammonia nitrogen content within permissible limits and minimize its impact on the environment.

Air Stripping: This method is commonly used in ammonia nitrogen wastewater treatment. It involves introducing gas into the wastewater to ensure thorough contact between dissolved gases and volatile solutes. By adjusting the pH, ionic ammonia in the wastewater is converted into molecular ammonia, which is then stripped out using air or steam, reducing the ammonia nitrogen content in the wastewater.

Chemical Precipitation: This method involves adding appropriate amounts of Mg²⁺ and PO₄³⁻ reagents to the ammonia nitrogen wastewater, causing a reaction with NH₄⁺ to form the insoluble double salt magnesium ammonium phosphate (MgNH₄PO₄·6H₂O) which precipitates out. The remaining nitrogen and phosphorus in the wastewater are then recovered.

Ion Exchange: The most common application of ion exchange in ammonia nitrogen wastewater treatment uses zeolite as the exchange medium to improve the ammonia nitrogen removal rate.

Membrane Absorption:

Reverse Osmosis: This method uses pressure exceeding the osmotic pressure of the solution to selectively retain solutes through a semi-permeable membrane, effectively separating solutes and solvents. It is characterized by low energy consumption, no pollution, advanced technology, and simple maintenance.

Electrodialysis: This technique uses an external DC electric field and the selective permeability of ion exchange membranes to separate ions from the electrolyte solution.

Biological Treatment: Nitrification-denitrification technology can be applied to ammonia nitrogen wastewater treatment, involving two stages: nitrification and denitrification.

However, each of these methods has its pros and cons. For example, air stripping has high energy consumption and can cause secondary pollution, with the effluent ammonia nitrogen still being relatively high. Traditional biochemical methods have issues such as long processes, large reactors, and extensive land use.

HP808 Ammonia Nitrogen Removal Adsorbent

To meet the needs of enterprises for high ammonia nitrogen removal rates, low design investment, low operating costs, advanced technology, and no secondary pollution, Haipu Functional Materials’ research team has developed an adsorbent product based on the characteristics of typical industry wastewater and treatment processes—HP808 Ammonia Nitrogen Removal Adsorbent.

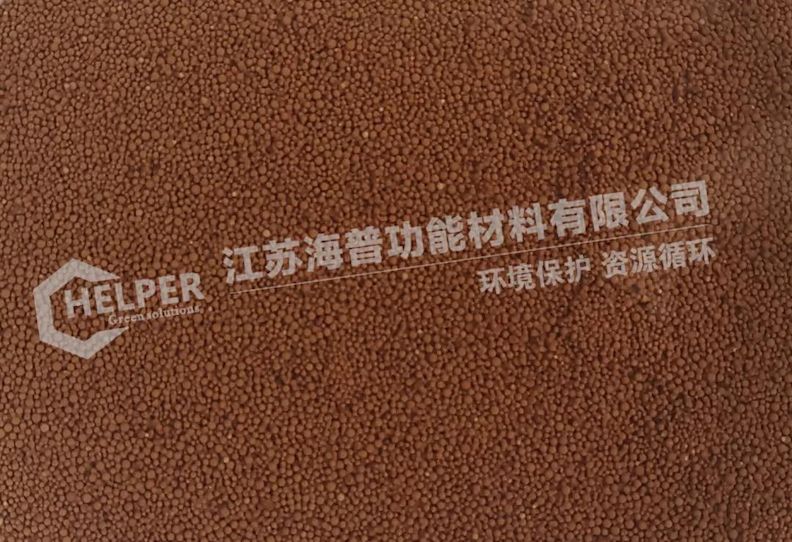

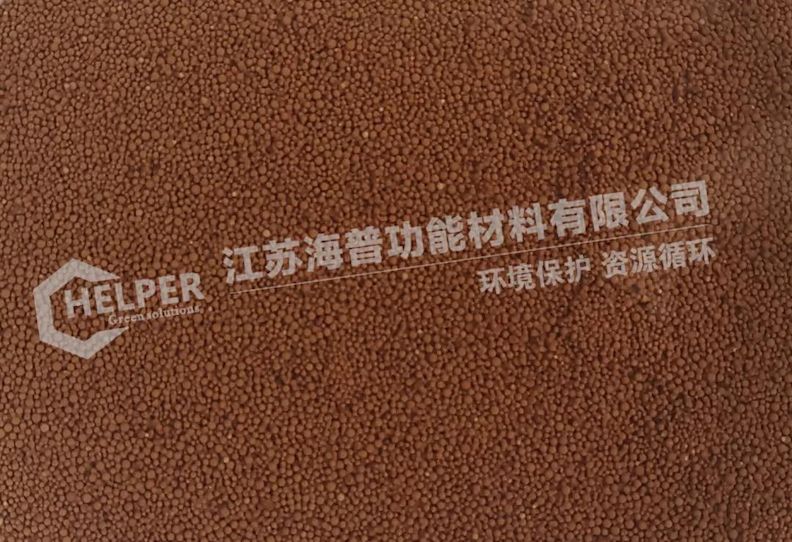

HP808 Ammonia Nitrogen Removal Adsorbent

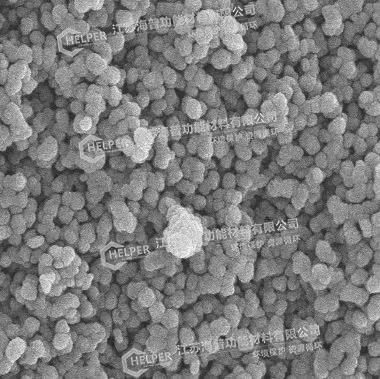

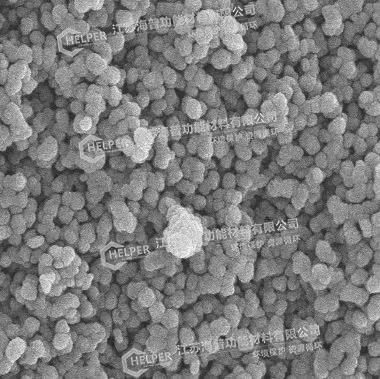

Rich Nanopores HP808 Ammonia Nitrogen Removal Adsorbent For treating wastewater containing inorganic ammonia

What Makes Our Ammonia Nitrogen Removal Adsorbent Different

Compared to other technologies, Haipu’s ammonia nitrogen removal adsorbent has significant advantages in terms of operating costs and efficiency.

Haipu’s ammonia nitrogen removal adsorbent is suitable for ammonia nitrogen wastewater, specifically targeting the adsorption and removal of ammonia nitrogen substances. It achieves high-efficiency adsorption and thorough desorption, with the treated wastewater meeting discharge standards.

After adsorption saturation, the adsorbent is regenerated using a desorption agent and can be reused for adsorption. The modular component design ensures high automation, simple operation, and ease of use.

Product Application Results

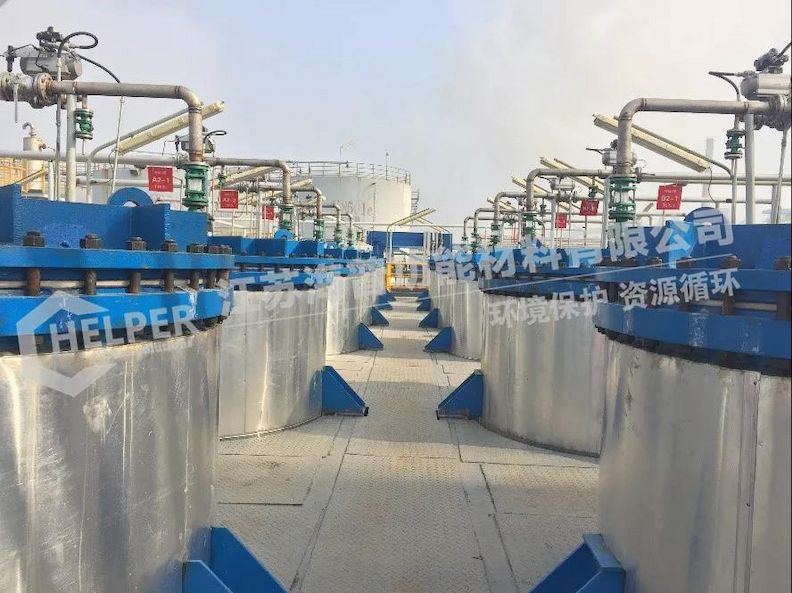

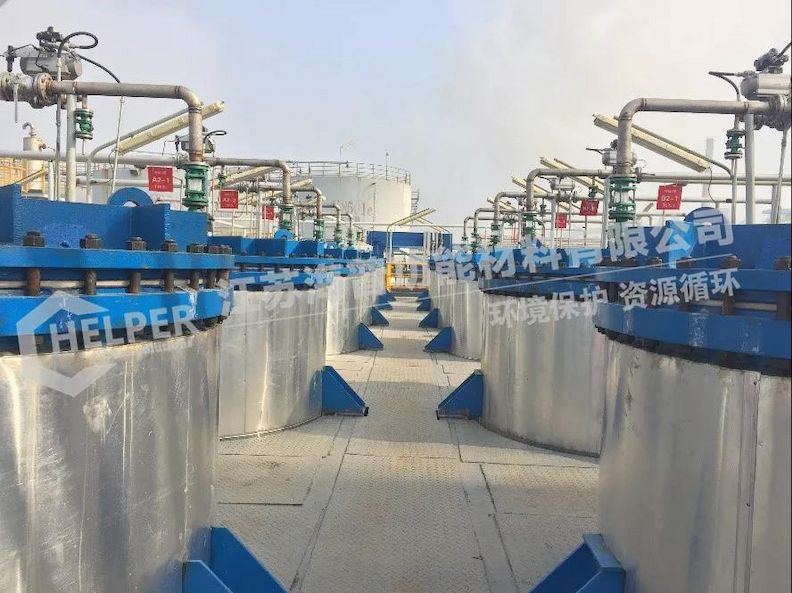

Relying on practical and feasible ammonia nitrogen removal adsorbent products and their supporting combination processes, Haipu has helped numerous clients meet their ammonia nitrogen wastewater treatment needs.

Ammonia Nitrogen Removal Adsorbent Application Case 1

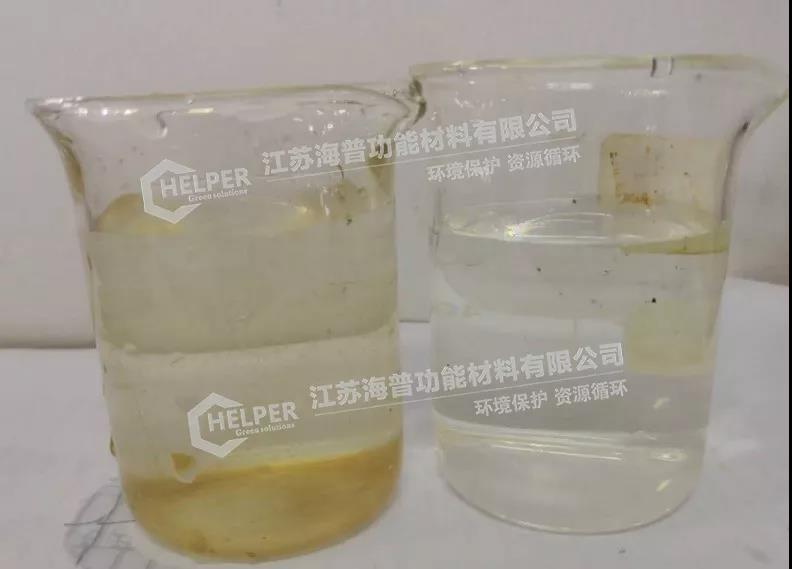

A biochemical company needed to treat 300 tons/day of ammonia nitrogen wastewater to address high ammonia nitrogen content and non-compliant biochemical treatment. Using Haipu’s ammonia nitrogen removal adsorbent, the wastewater first undergoes adsorption to remove most of the ammonia nitrogen substances, then enters the biochemical system for treatment, with the effluent meeting discharge standards.

| Raw Water Ammonia Nitrogen Content | Treated Water Ammonia Nitrogen Content | Removal Rate |

| 300mg/L | 25mg/L | 92% |

| 300mg/L | 24mg/L | 92% |

| 300mg/L | 25mg/L | 92% |

Ammonia Nitrogen Removal Adsorbent Application Case 2

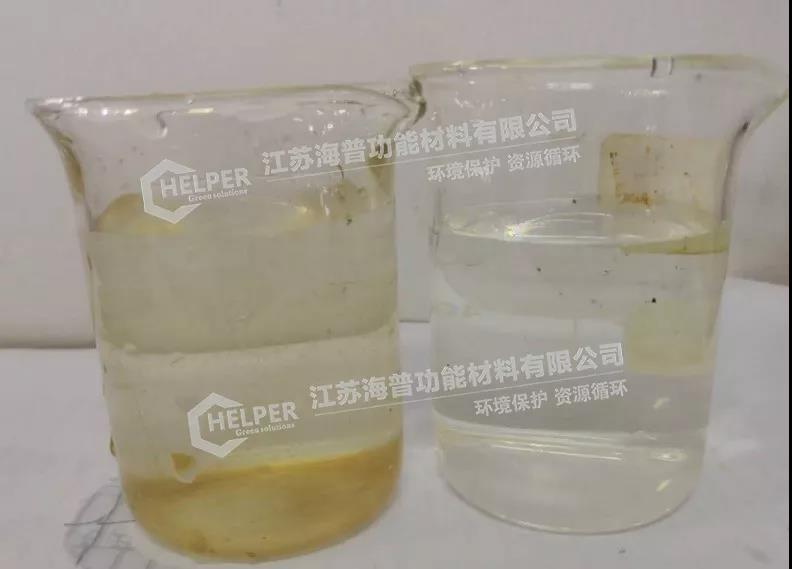

A company required the treated wastewater to have an ammonia nitrogen content below 20 mg/L. Experimental results showed that using Haipu’s ammonia nitrogen removal adsorbent for adsorption treatment, the ammonia nitrogen removal rate remained stable above 90%, with the effluent ammonia nitrogen content controlled below 10 mg/L. This not only meets the client’s requirements but also provides a safety margin to effectively prevent non-compliance due to fluctuations in the influent wastewater quality.

| Raw Water Ammonia Nitrogen Content | Treated Water Ammonia Nitrogen Content | Removal Rate |

| 112.1mg/L | 7.2mg/L | 93.58% |

| 112.1mg/L | 7.8mg/L | 93.76% |

| 112.1mg/L | 7.8mg/L | 93.76% |

Comparison of Adsorption Inlet and Outlet Water

Actual Case Demonstration of Ammonia Nitrogen Removal Adsorbent Application

CN

CN