Electroplating products have a wide range of applications and are an indispensable part of the socio-economic development of our country. However, it is also one of the world’s three major polluting industries.

Electroplating enterprises generate a large amount of industrial wastewater during production and operation. Due to the diversity of products and differences in performance requirements, the water quality is very complex, usually consisting of various heavy metal ions.

The wastewater generated during the electroplating process generally has the following characteristics:

Variety of Pollutants: Depending on the functional use of the plated parts, the wastewater contains various pollutants such as petroleum, surfactants, ammonia nitrogen, phosphorus, various heavy metals, and cyanides.

High Concentration of Pollutants: Due to the need for periodic replacement and discharge of electroplating bath solutions, and the carryover of bath solutions by parts of different shapes, the concentration of various pollutants in the wastewater is high, with a general salt content of about 1%. If not treated, it will significantly impact the surrounding environment, causing rapid ecological degradation.

Fluctuating Water Quality: Due to the complexity of production and changes in the demand for plated parts, the types and concentrations of pollutants in the wastewater vary greatly.

Complex Traditional Treatment Processes: Faced with various pollutants and mixed heavy metals, traditional processes require separate collection and classification of pollutants based on their different properties, necessitating the setup of at least 7-9 types of pretreatment systems before comprehensive treatment.

Current Status of Electroplating Wastewater Treatment

Electroplating wastewater contains pollutants such as cyanides (CN⁻), acids and bases, heavy metal ions, and organic substances. It is challenging to remove all pollutants using a single treatment process. Currently, commonly used treatment methods include chemical precipitation, adsorption, membrane separation, electrolysis, ferrite method, and extraction.

Chemical Precipitation: The most widely used method domestically and internationally, it is simple and can simultaneously remove various metal ions from wastewater. However, it generates a large amount of heavy metal sludge, which cannot be directly dumped or landfilled and requires further treatment.

Membrane Separation: Simple to operate, with low energy consumption as the dialysis process does not consume electricity except for liquid pumping. However, it requires significant equipment investment, frequent membrane cleaning and replacement, and the concentrated solution still needs to be treated to meet standards before discharge.

Electrolysis: High energy consumption and cost, with side reactions such as hydrogen and oxygen evolution causing energy waste. Continuous long-term operation can lead to electrode surface passivation, resulting in low efficiency and high electricity consumption.

Ferrite Method: Requires heating (about 70°C), leading to high energy consumption and increased treatment costs.

Extraction: Highly selective extractants are specific, but solvent loss is significant during extraction and regeneration, with high energy consumption during regeneration, making it unsuitable for general wastewater treatment.

Adsorption: Deeply removes metal ions from wastewater, with nickel and chromium ion concentrations controllable below 0.1 mg/L. It allows for the recovery of metal ions from wastewater, achieving resource utilization and reducing production costs for enterprises.

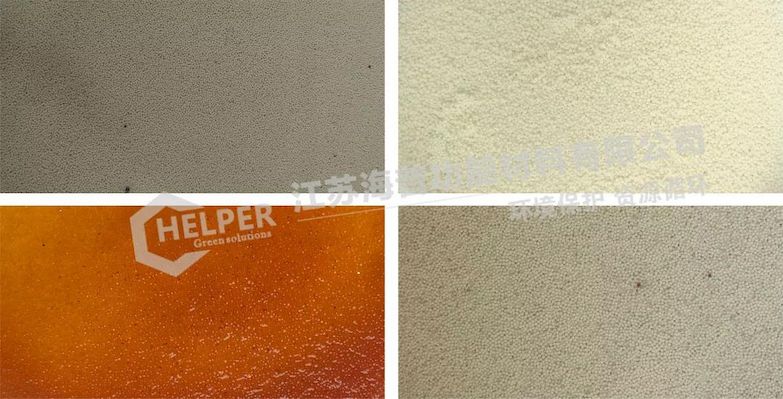

Adsorbents for Electroplating and Metallurgical Industries - HP8/HP4020/HP606/KF340

To meet the requirements for compliant treatment and recovery adsorption of electroplating and metallurgical wastewater, Haipu Functional Materials’ research team has developed a series of adsorbent products based on the characteristics of typical industry wastewater and treatment processes—HP4020/HP8/HP606/KF340.

Adsorbents for Electroplating and Metallurgical Industries

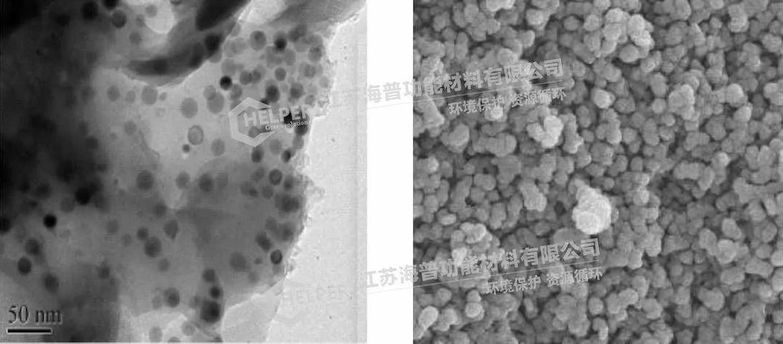

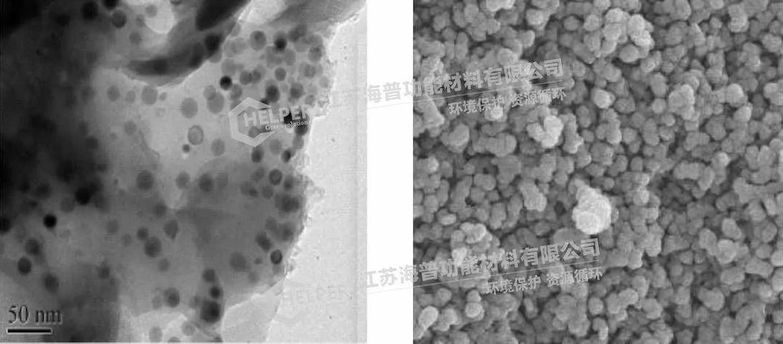

Active Nanoparticles and Rich Nanopores Under Microscope

HP4020/HP606/HP8/KF340

For Adsorption Recovery and Compliant Treatment of Electroplating and Metallurgical Wastewater

What Makes Our Special Adsorbents Different

Compared to other treatment technologies, Haipu’s special adsorbent materials have a large adsorption capacity, are regenerable, and have a long service life.

They can be implemented in modular components, allowing flexible adjustment based on production capacity, saving space, and having a compact structure.

High degree of automation, short process flow, simple operation, and low energy consumption.

After adsorption saturation, the adsorbent is regenerated using a desorption agent and can be reused for adsorption.

Product Application Results

Relying on practical and feasible special adsorbent products and their supporting combination processes, Haipu has helped numerous clients in the electroplating and metallurgical industries achieve compliant treatment.

Application Case 1

An electroplating enterprise mainly engaged in electroplating services for the automotive, aviation, aerospace, and nuclear power sectors had a 120 t/h wastewater treatment facility where the terminal effluent nickel content could not consistently meet standards.

Using our special adsorbent materials for deep nickel removal, the effluent nickel content was reduced to less than 0.05 mg/L, far below the enterprise’s discharge requirement (0.1 mg/L), solving the problem of excessive nickel in the wastewater and promoting sustainable development for the enterprise.

| Inlet Concentration | Outlet Concentration | Removal Rate |

| ~2mg/L | 0.048mg/L | 97.60% |

| ~2mg/L | 0.039mg/L | 98.05% |

| ~2mg/L | 0.045mg/L | 97.75% |

Application Case 2

An electroplating industrial park generated 1062 tons of zinc-containing wastewater daily, with excessive zinc and nickel ions. Using our special adsorbent materials and process design, the effluent nickel and zinc levels met discharge standards.

The effluent nickel ion concentration was stabilized below 0.1 mg/L, and zinc ion concentration below 1 mg/L, solving the wastewater treatment challenges of the industrial park.

| Raw Water Zinc Content | Treated Water Zinc Content | Removal Rate |

| 41mg/L | <1mg/L | >97.6% |

| Inlet Nickel Content | Outlet Nickel Content | Removal Rate |

| 0.4mg/L | <0.1mg/L | >75% |

Application Case 3

An electroplating industrial park generated 1125 tons of cyanide copper wastewater daily, with excessive copper and nickel ions. Using our special adsorbent materials and process design, comprehensive multi-stage treatment was implemented.

The terminal effluent nickel concentration was stabilized below 0.1 mg/L, and copper concentration below 0.3 mg/L, meeting enterprise requirements, allowing the effluent to be directly sent to the intermediate water tank for further treatment.

| Raw Water Copper Content | Treated Water Copper Content | Removal Rate |

| 95mg/L | <0.3mg/L | >99.7% |

| Raw Water Nickel Content | Treated Water Nickel Content | Removal Rate |

| 10mg/L | <0.1mg/L | >99.4% |

Application Case 4

An electroplating enterprise serving the electronics and communications industries generated 200 tons/day of chromium-containing wastewater. Using our special adsorbent materials and process design, deep removal of chromium from the wastewater was achieved.

The chromium removal rate was consistently above 90%, with the effluent chromium content being very low, far below enterprise requirements and discharge standards.

| Raw Water Chromium Content | Treated Water Chromium Content | Removal Rate |

| 5.7mg/L | 0.275mg/L | 95.20% |

| 5.7mg/L | 0.306mg/L | 94.60% |

| 5.7mg/L | 0.279mg/L | 95.10% |

Actual Case Demonstrations of Adsorbent Applications for Electroplating and Metallurgical Wastewater Treatment

CN

CN