Current situation of handling the problem of excessive heavy metals

China is currently in a period of rapid economic development, and the activities of heavy metal mining, smelting, processing, and product manufacturing are increasing. The problem of heavy metal pollution is gradually becoming prominent and showing a high incidence trend.

According to statistics, China produces about 40 billion tons of industrial wastewater annually, of which heavy metal wastewater accounts for about 60%.

These wastewater seriously pollute surface water and groundwater, with a pollution rate of up to 80.1% in the sediment of rivers, lakes, and reservoirs. The problem of heavy metal pollution in water bodies is particularly prominent.

Due to the fact that heavy metals cannot be degraded by microorganisms, their pollution of environmental media has the characteristics of concealment, long-term, and accumulation. Therefore, a universally effective treatment method has not yet been found.

At the same time, there are the following difficulties in the treatment of heavy metal wastewater:

(1) The pH value of sewage treatment agents is difficult to control (a more mature treatment method is generally to adjust the pH value to a certain range, so that a part of the free heavy metal ions are fixed in the form of hydroxides, thereby reducing the use of heavy metal ion removal agents and lowering treatment costs. The pH value needs to be continuously detected in the treatment process to ensure that the hydroxide ions in the wastewater are within the appropriate range.)

(2) Cannot simultaneously remove multiple heavy metal elements from wastewater (conventional wastewater treatment methods can only have good removal effects on a single heavy metal ion)

(3) The recovery of heavy metal ions in wastewater is difficult (some heavy metal wastewater contains precious metals such as Ag and Au, and the recovery of these precious metals has significant economic benefits. Currently, the commonly used methods for recovering heavy metal ions are electrodialysis and electrodeposition, but the equipment used in these methods generally occupies a large area, consumes high energy, and ultimately has low recovery efficiency).

In industries such as electroplating and mining, in some cases, the heavy metal content in wastewater can reach 105mg/L, which seriously exceeds the national discharge standards.

According to the types and toxicity of heavy metal elements in wastewater, the heavy metal content in wastewater allowed by the state must be controlled within 0.005-2mg/L. Therefore, heavy metal wastewater must undergo heavy metal ion removal treatment before discharge.

At present, the commonly used treatment methods for heavy metal wastewater include chemical precipitation, electrochemical method, biological method, membrane separation method, adsorption method, etc.

However, each method has its own advantages and disadvantages. Adsorption method has been widely used for the treatment of heavy metal wastewater due to its advantages of simple operation, low investment, good selectivity, and high removal rate.

Product Introduction

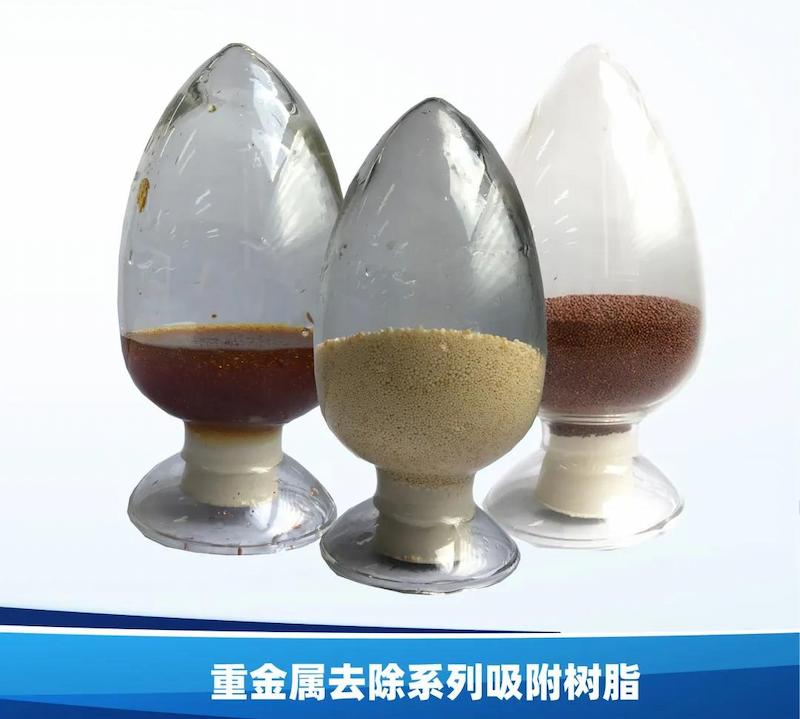

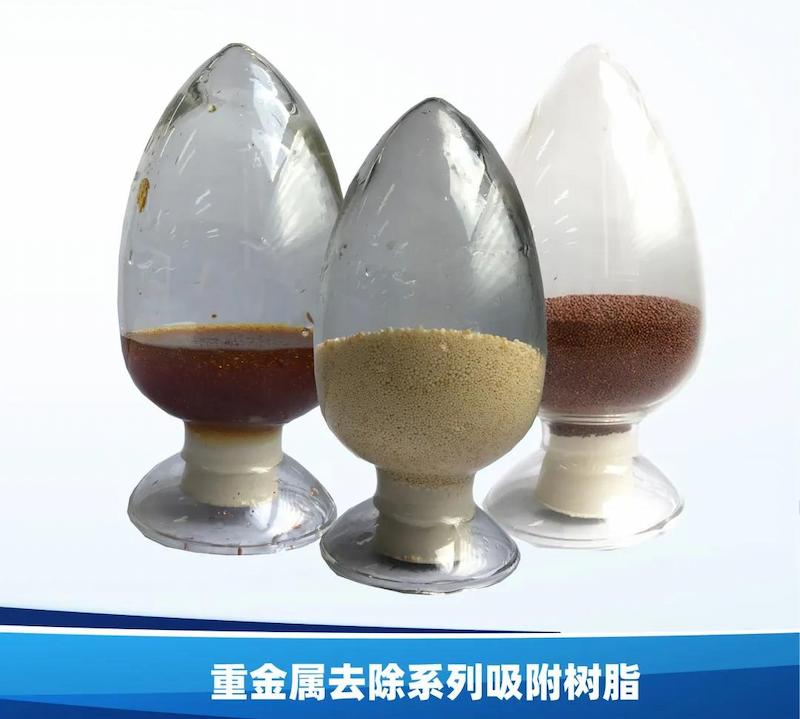

In response to the current need for a cost-effective, environmentally friendly, and efficient method for removing heavy metals from wastewater, Jiangsu Haipu Functional Materials Co., Ltd. has developed a series of products - heavy metal removal adsorption resins (models such as HP8/HP606/HP4020/KF340/KF400/HT609)

*Heavy metal removal adsorption resin series products

There are different models of products to choose from according to different application scenarios and processing objects. Haipu's heavy metal removal adsorption resin materials have advantages such as large adsorption capacity, renewable use of adsorption materials, and long service life.

Product parameters

When in use, Haipu heavy metal removal adsorption resin products can deeply remove metal ions from wastewater, and the concentration of nickel and chromium ions can be controlled below 0.1mg/L; At the same time, targeting the recyclable metal ions in wastewater, adsorption can achieve the resource utilization of wastewater and reduce the production cost of enterprises.

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to be regenerated. This process continues in a continuous cycle.

Product and its supporting process characteristics

The treatment of heavy metal wastewater needs to include the following three points: 1. Efficient and stable removal of heavy metals from wastewater. Thirteen types of Class I pollutants, including total mercury, total cadmium, total chromium, hexavalent chromium, total lead, and total nickel, must meet the emission standards at the workshop or workshop treatment facility outlet, and other metal ions must meet the emission requirements at the enterprise discharge outlet; 2. Low initial investment cost, low operating cost, and convenient equipment operation and maintenance; 3. Advanced and reliable technology, no secondary pollution.

In response to the above processing requirements, the advantages of Haipu heavy metal removal adsorption resin products and their supporting processes are as follows:

Simple process: Simple process, easy operation, low labor intensity, small footprint, low investment.

Excellent craftsmanship: capable of implementing modular component forms, flexible adjustment according to production capacity, high degree of automation, short process flow, and low energy consumption.

Low cost: Low operating cost, stable and reliable treatment effect, able to withstand certain water quality fluctuations and impacts.

Green and environmentally friendly: mild usage conditions, long equipment lifespan, simple maintenance, minimal subsequent investment, no hazardous waste generated in the process, no secondary pollution, making it a green and environmentally friendly solution.

Product application effect

Haipu heavy metal removal adsorption resin products and their supporting combination processes have helped multiple customers meet their relevant treatment needs.

01

Wastewater heavy metal removal project

Wastewater quality: Wastewater mainly includes nickel, copper, chromium, zinc, etc., and most heavy metals exist in complex form. After being treated by physical and chemical methods such as breaking the network and precipitation, the copper, chromium, and zinc in the effluent can meet the relevant discharge requirements, but nickel still has a concentration of 0.8-2.0 mg/L.

Processing requirements: Nickel requires deep processing to ensure compliance with emission standards.

Processing result:

| Water volume (m³/d) | Nickel ion (mg/L) | Appearance |

| Raw water | 3000 | 0.8-2 | Water clear |

| Effluent | 3000 | <0.1 | Water clear |

*Adsorption resin product processing data

02

Electroplating Enterprise Wastewater Heavy Metal Removal Project

Wastewater quality: The electroplating enterprise's wastewater contains heavy metals such as zinc and nickel. After alkaline precipitation pretreatment, the filtered wastewater is subjected to adsorption treatment, and the removal rate of heavy metal ions in the wastewater reaches over 99%. The adsorbed zinc and nickel ions in the effluent meet the discharge standards.

Processing result:

| Zinc content in raw water | Zinc content in effluent | Removal rate |

| 238.4mg/L | 0.3mg/L | 99.87% |

| Nickel content in raw water | Nickel content in effluent | Removal rate |

| 68.2mg/L | 0.09mg/L | 99.85% |

*Adsorption resin product processing data

03

Electroplating Enterprise Wastewater Heavy Metal Removal Project

Wastewater quality: The government's control value for nickel is set at less than 0.1mg/l. In order to ensure stable and compliant discharge of the system, our company's special adsorption materials were used for process design of the wastewater. The adsorbed water meets the standard of nickel less than 0.1 mg/L.

Processing result:

| Source | Water volume | Nickel(mg/L) | Chromium(mg/L) | Zinc(mg/L) | Iron(mg/L) | Copper(mg/L) |

| Inlet | ≤1000m³/d | ≤0.5 | ≤2.0 | ≤0.5 | ≤0.5 | ≤2.0 |

| Effluent | ≤1100m³/d | ≤0.5 | / | / | / | / |

*Adsorption resin product processing data

04

Heavy metal wastewater from a certain enterprise

Wastewater quality: The nickel ion content in the wastewater of a certain enterprise is about 700mg/L. Treatment requirements: nickel content ≤ 0.1mg/L. The water quality before and after treatment is shown in the table below.

Processing result:

| Water volume (m³/day) | Nickel ion (mg/L) |

| Raw water | 200 | 706.3 |

| Effluent | 200 | 0.05 |

*Adsorption resin product processing data

05

Heavy metal wastewater treatment project for electroplating enterprises

Wastewater quality: The wastewater generated by the electroplating workshop contains 5-10 mg/L nickel and 5-10 mg/L copper, which cannot be discharged in compliance with standards.

Processing requirements: Nickel<0.1 mg/L, copper<0.3 mg/L.

Processing result:

| Water volume | Nickel(mg/L) | Copper(mg/L) | pH |

| Raw water | 300 t/d | 7.99 ppm | 6.48 ppm | ~6 |

| Effluent | 300 t/d | ~0.06 | ~0.2 | ~6 |

*Adsorption resin product processing data

On site treatment of resin products and supporting processes

*Project site

CN

CN