With the vigorous development of modern industrial technology, especially the large-scale construction of factories in industries such as electronics, metallurgy, steelmaking, aluminum electrolysis, chemical engineering, and pesticides, fluoride pollution has become increasingly serious in recent years. Local fluoride levels have exceeded the standard, causing fluorosis and bone disease in surrounding people and livestock, resulting in stunted or even necrotic plants. Therefore, fluoride pollution has also received increasing attention from people. In order to reduce the harm of excessive fluoride to human health, the fluoride content in industrial wastewater must be strictly limited. In response to this issue, various methods for treating fluorine-containing industrial wastewater have emerged.

So far, certain achievements have been made in the theory, process, and technology of fluoride removal. However, the types and components of industrial wastewater are relatively complex, leading to problems such as cumbersome processes, excessive addition of chemicals, and high treatment costs in the wastewater defluorination process. Therefore, seeking simple, efficient, and low-cost methods for fluoride removal from wastewater is of great significance for environmental governance and long-term human development.

1. Wastewater treatment methods:

At present, the treatment methods for fluorine-containing wastewater used in industry mainly include precipitation method, adsorption method, ion exchange method, membrane separation method, etc. The advantages and disadvantages of each process are compared as follows:

| Processing technology | Advantage | Shortcoming |

| Precipitation method | Chemical precipitation method | The method is simple, easy to handle, and has low cost | To some extent, there are difficulties in meeting the standards for treated effluent, slow sedimentation of sludge, and difficulty in dewatering |

| Coagulation sedimentation method | Not only can it remove fine suspended particles from wastewater, but it can also remove nutrients such as chromaticity, oil content, microorganisms, nitrogen and phosphorus, heavy metals, and organic matter | The coagulation sedimentation tank generally has the disadvantages of large body size, large footprint, long retention time, large amount of sludge generation, and difficulty in meeting effluent standards. |

| Adsorption method | Continuous, efficient, and stable deep treatment of organic matter, improving the BOD/COD of wastewater, ensuring the subsequent biochemical treatment of enterprises, renewable use of adsorption materials, long service life, land saving, compact structure, high degree of automation, and simple operation. | The adsorption method requires the addition of special treatment agents and the installation of specific equipment, resulting in higher treatment costs than the precipitation method. |

| Ion exchange method | The equipment is simple, easy to operate, cost-effective, pollution-free, and has good fluoride removal effect, making it an ideal method for deep removal of fluoride ions from water. | Excessive regeneration waste liquid will be generated, the adsorption cycle is long, and a large amount of desorbent will be consumed. Discharging a large amount of saline wastewater can easily cause pipeline corrosion, expensive materials, and difficult resin regeneration treatment. |

| Membrane separation method | Non polluting environment, low energy consumption, high efficiency, simple process, etc. Especially the reverse osmosis (RO) membrane separation process is widely used for fluoride removal from wastewater, and RO membranes exhibit high retention capacity for fluoride ions | The investment is large, the operation process is complex, and the membrane service life is short, requiring frequent replacement of the membrane. |

2. Introduction to Haipu customized process:

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a company that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to provide customers with solutions.

A national high-tech enterprise that solves relevant environmental problems. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

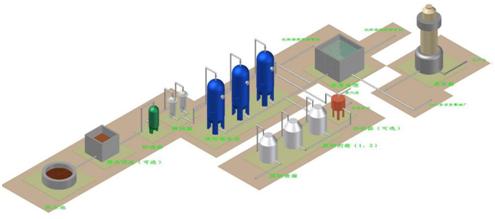

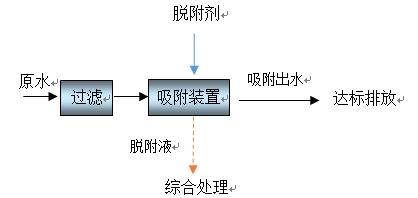

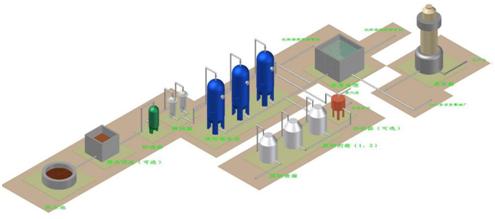

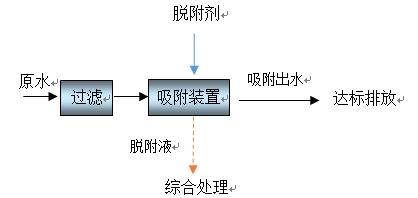

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to be regenerated. This process is continuously repeated. The conventional process of treating wastewater by adsorption method is shown in the following figure.

Process flowchart

Conventional process diagram for adsorption treatment of wastewater

When using Haipu's adsorption process to treat fluorine-containing wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower selectively adsorbs and enriches fluorine in the wastewater, reducing the fluoride concentration in the adsorbed water. After adsorption saturation, the adsorbent material is subjected to desorption treatment to regenerate and resume adsorption, and this process is continuously repeated.

Process flowchart

3. Case Introduction

This newly built fluoride removal wastewater adsorption treatment facility has a total designed wastewater treatment capacity of 600m³/d. It uses adsorption technology to treat fluoride containing wastewater. Experiments have shown that the use of special adsorbents can effectively reduce the fluoride concentration in wastewater. The specific treatment data is shown in the table below:

| Index | Fluorine(mg/L) |

| Absorb incoming water | 28.8 |

| Adsorbed water | 1.33 |

Processing rendering, from left to right are raw water and adsorbed effluent, respectively

From the above figure and table, it can be seen that the filtered water of the raw water is treated with a special adsorbent and the effluent is colorless. The fluoride in the wastewater is almost completely removed. The experiment proves that using a special adsorbent for adsorption can effectively reduce the fluoride concentration in the wastewater.

4. Advantages of adsorption method for fluoride removal:

At present, the treatment methods for fluorine-containing wastewater have their own shortcomings in terms of treatment effectiveness and operating costs. The adsorption method can effectively remove fluoride from wastewater below the emission limit, making it an economical and effective method for treating fluorine-containing wastewater. Its advantages include the following:

(1) Stable compliance with emission standards or returning to production lines can effectively alleviate the environmental pressure on enterprises.

(2) Conduct experiments on the sampling samples of wastewater generated on the enterprise site, based on technology, and design adsorption processes based on experiments. The matching degree between wastewater and processes is 100%.

(3) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs.

(4) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install.

(5) Advanced and mature technology, pollution-free, with strong technical support and abundant resources.

CN

CN