The demand for phosphorus containing wastewater treatment is becoming increasingly common in China, as phosphorus is one of the main elements that make up life and has wide application value in industrial and agricultural production.

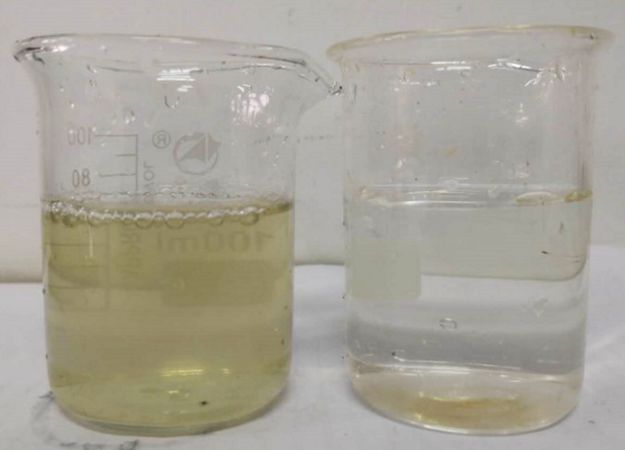

With the vigorous development of modern industry, the discharge of phosphorus containing wastewater from industries such as chemical, textile printing and dyeing, pesticides, petrochemicals, pharmaceuticals, and food is gradually increasing. This not only causes environmental pollution and deterioration of surface water bodies (as shown in Figure 1), threatening human health, but also leads to the waste of phosphorus resources.

The comprehensive discharge standard for sewage in China (GB8978-1996) requires that the first level standard phosphate (calculated as P) should be ≤ 0.5 mg/L, and the second level standard phosphate (calculated as P) should be ≤ 1.0 mg/L. Therefore, an economically effective method is needed for the treatment of phosphorus containing wastewater.

Figure 1 Phosphorus containing wastewater discharge and eutrophication of water bodies

There are various methods for treating phosphorus containing wastewater, and the most commonly used ones in engineering currently include chemical methods, biological methods, and adsorption methods.

01

Pharmaceutical method for treating phosphorus containing wastewater

Pharmaceutical phosphorus removal is the earliest and most widely used method, which involves adding chemical agents such as lime, aluminum salts, iron salts, and organic compounds to water to generate insoluble phosphate, and then using precipitation, air flotation, or filtration methods to remove phosphorus from wastewater.

This method is suitable for the pretreatment of high concentration inorganic phosphorus wastewater, but it is generally difficult to directly meet the discharge requirements. Even if excessive chemicals are used, they often cannot stably meet the standards. At the same time, it is prone to secondary pollution, high operating costs, and the production of a large amount of sludge.

02

Biological methods for treating phosphorus containing wastewater

Biological phosphorus removal refers to the controllable phosphorus removal effect achieved by phosphorus accumulating microorganisms releasing phosphorus through the anaerobic stage and absorbing phosphorus beyond their physiological needs in the aerobic stage. Although this method has low cost and minimal pollution; But high requirements are needed for the inflow, with pH between 6-9, BOD/COD greater than 0.3, large sludge volume, and difficulty in microbial cultivation.

And with the continuous improvement of high phosphorus wastewater treatment requirements, the single biological method for treating phosphorus containing wastewater cannot meet the discharge requirements.

03

Adsorption method for phosphorus containing wastewater treatment

Relying on the physical or chemical adsorption between adsorbents and phosphorus in wastewater to achieve the goal of removing phosphorus

After adsorption saturation, desorption treatment of the adsorbent can recover phosphorus resources. The high-efficiency phosphorus removal adsorbent has no strict requirements for the influent and the treatment effect is stable.

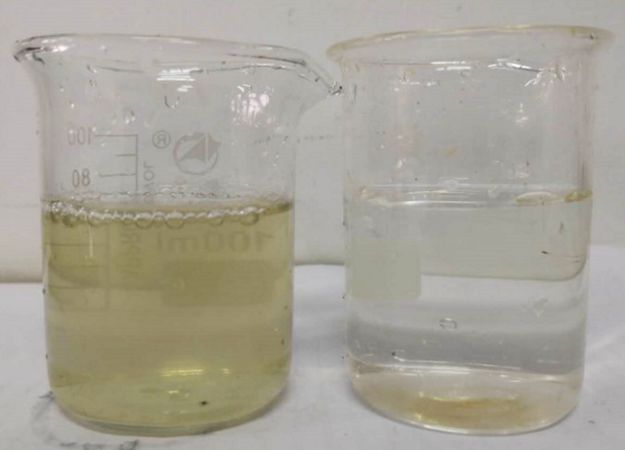

In view of this, our company has developed a series of high-performance phosphorus removal adsorbents based on the characteristics of phosphorus containing wastewater and the physicochemical properties of phosphorus ions. They can be used for the standard treatment of inorganic. phosphorus and organic phosphorus wastewater, as shown in Figure 2. After treatment with phosphorus removal adsorbents, the yellow phosphorus containing wastewater becomes basically colorless, and the effluent phosphorus content is ≤ 0.5mg/L.

Practical application of phosphorus removal adsorbent

Our company adopts self-developed special phosphorus removal adsorbents and supporting application processes based on the water quality characteristics of phosphorus containing wastewater in various industries and the physicochemical properties of related pollution factors, achieving efficient treatment of related wastewater and recovery of phosphorus resources.

A certain biochemical enterprise can generate about 70 tons of phosphorus containing wastewater per day. The phosphorus in the wastewater includes organic phosphorus and inorganic phosphorus, with a total phosphorus concentration of about 634mg/L. The effluent phosphorus concentration is required to be less than 6mg/L.

The data before and after processing are shown in Table 1 below

| Raw Water Phosphorus Content | Treated Water Phosphorus Content | Removal Rate |

| ~634mg/L | 5.2mg/L | -99.00% |

Table 1 Comparison of phosphorus content in raw water and treated effluent

A pesticide intermediate enterprise produces 5000 tons/day of phosphorus containing wastewater during production, with a raw water concentration of~3.0mg/L, containing various organic and inorganic phosphorus, and requiring effluent phosphorus to be less than 0.3mg/L.

After pre-treatment and special adsorbent treatment, our company's data is shown in Table 2 below

| Raw Water Phosphorus Content | Treated Water Phosphorus Content | Removal Rate |

| ~3mg/L | ≤0.2mg/L | >90.0% |

Table 2 Comparison of phosphorus content in raw water and treated effluent

50 tons/day of organic phosphorus wastewater is generated in the production of a certain fine chemical enterprise. The phosphorus content of the raw water is about 1000 mg/L, containing various organic phosphorus and highly emulsified. The effluent phosphorus is required to be less than 20mg/L to reduce the subsequent biochemical pressure.

After being treated with our company's relevant adsorbents and application processes, the effluent can be stably controlled to ≤ 15mg/L

| Raw Water Phosphorus Content | Treated Water Phosphorus Content | Removal Rate |

| ~1000mg/L | ≤15mg/L | >98.0% |

Table 3 Comparison of phosphorus content in raw water and treated effluent

A certain agricultural chemical enterprise generates 300 tons/day of organic phosphorus wastewater during production, with a raw water organic phosphorus product content of nearly 20000mg/L and a total phosphorus content of 12000mg/L. This puts great pressure on subsequent biochemical processes and causes waste of phosphorus products.

The customer expects based on the concept of clean production, source resource management, recycling of 90% organic phosphorus products, while reducing the load of subsequent biochemical treatment.

After our company's relevant solutions, the recovery rate of organic phosphorus products is ≥ 90%

Table 4 Comparison of phosphorus content in raw water and treated effluent

Figure 2: Phosphorus containing raw water (left) and treated effluent (right)

On site projects related to phosphorus removal adsorbents

Figure 3 Project Site Photo

Figure 4 Project Site Photo

Figure 5 Project Site Photo

CN

CN