In order to promote and deepen VOCs governance, starting from the 12th Five Year Plan, relevant national departments have successively issued a series of policies to promote the VOCs governance process, and many enterprises have also begun to layout their business towards VOCs governance.

In September 2013, the State Council issued the "Action Plan for Air Pollution Prevention and Control", which specified that key industries such as petrochemicals, organic chemicals, surface coating, packaging and printing need to carry out VOCs control.

At the same time, the Ministry of Environmental Protection and six other departments jointly issued the "Implementation Rules for the Action Plan for Air Pollution Prevention and Control in Beijing Tianjin Hebei and Surrounding Areas", requiring 559 enterprises in key industries such as organic chemicals, pharmaceuticals, surface coating, plastic products, packaging and printing to carry out comprehensive VOCs control by the end of 2017.

The "2020 Volatile Organic Compounds Governance Plan" issued in 2020 pointed out the need to vigorously promote the substitution of low (no) VOCs content raw and auxiliary materials, and to include enterprises that fully use low VOCs content raw and auxiliary materials that meet national requirements in the positive list and government green procurement list.

In the foreseeable future, VOCs prevention and control will become one of the 'protagonists' on China's pollution control stage, contributing significantly to the further improvement of air quality and even carbon reduction during the 14th Five Year Plan period.

New situation of VOCs control

At the beginning of the 14th Five Year Plan, "reducing pollution and carbon emissions" has become a new hot topic in the fields of ecological civilization construction and ecological environment protection.

VOCs governance has also ushered in a refined and specialized new market ecology, and energy conservation and safety will become the main focus of engineering. Precise governance of small and medium-sized enterprises has become a key control point.

Research data shows that in 2015, China's annual emissions of anthropogenic VOCs reached about 25 million tons, far exceeding the level of the United States and the European Union.

In anthropogenic emissions, petrochemical, chemical, industrial coating, and packaging printing account for about 70% of industrial VOCs emissions, while oil storage, transportation, and sales processes account for about 20% of transportation emissions.

There are problems with VOCs control

With the achievements of VOCs control over the past few years, the governance of key industries (enterprises) has been well regulated.

The VOCs treatment market is gradually shifting towards non key polluting industries (enterprises), which lack professional control as a whole, especially in the field of treatment engineering, and there are many treatment problems.

For example, poor exhaust gas collection efficiency, incorrect process selection, mismatch between air volume and equipment, and historical legacy issues in key industries (enterprises) such as low safety, high energy consumption, and unorganized emissions.

Encourage the application of new technologies and materials

In recent years, with the gradual decline of technologies such as plasma and photo oxidation, the number of VOCs treatment end equipment treatment technology processes has decreased, and the technical solutions of each company are becoming more and more similar. The proportion of business in project selection is increasing, leading to chaotic and uneven competition in the industry.

In the face of shortages of new technologies/materials and focusing only on some chains, efforts should be made to strengthen the construction of demonstration points for new technologies/materials (government guidance for the application of new technologies/materials), encourage the trial use of new technologies/materials (such as using actual long-term standards as the main criterion for acceptance), and promote balanced development in all aspects of environmental protection governance (especially in the training of specialized talents to assist in the design of waste gas treatment pipelines).

*Haipu VOCs waste gas special adsorption treatment

The series of special adsorption materials and application processes developed by Jiangsu Haipu Functional Materials Co., Ltd. can achieve effective treatment and resource recovery of various VOCs.

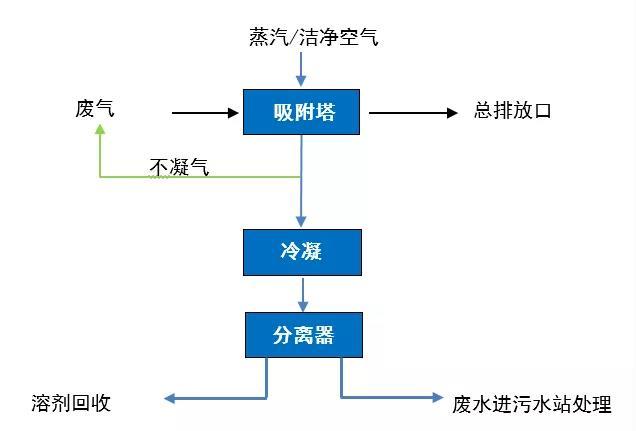

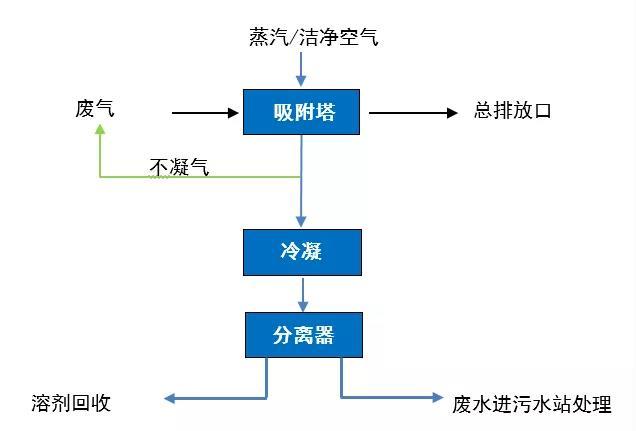

In terms of processing principle, the relevant VOCs waste gas is first extracted by a vacuum pump and then subjected to secondary condensation. The condensed and liquefied components are received in a storage tank, and the uncondensed waste gas is connected to an adsorption tower containing nano adsorbents for adsorption and enrichment. After adsorption, the waste gas can meet the emission standards.

After the adsorbent is saturated with adsorption, it is blown off. The mixture of blown off components and water vapor is then condensed and liquefied, and allowed to stand and separate into layers for separation and recovery. This process can achieve a removal rate of over 98% for dichloroethane in waste gas, and is also suitable for the treatment of waste gases such as dichloromethane, toluene, and dibromopropane

If a chemical enterprise uses Haipu VOCs adsorbent for adsorption treatment of 2000m³/h dichloromethane waste gas, the vast majority of dichloromethane components in the waste gas can be recovered, and 1296kg of dichloromethane can be recovered per day, increasing the economic benefits of the enterprise.

| Air volume | Concentration of dichloromethane in the intake air | Dichloromethane emission concentration |

| 2000m³/h | 30000mg/m³ | ≤40mg/m³

|

A production workshop of a certain enterprise produces 3000m³/h of dichloroethane waste gas with a concentration of 30000mg/m³.

After comprehensively comparing the feasibility, investment and operational economy, convenience and safety reliability of various treatment technologies, the enterprise has decided to use Haipu VOCs adsorbent for adsorption treatment.

After processing, the content of dichloroethane is ≤ 30mg/m³, ensuring that it can be integrated into the subsequent RTO system after exhaust.

| Air volume | Intake dichloroethane concentration | Emission concentration of dichloroethane |

| 3000m³/h | 30000mg/m³ | ≤30mg/m³ |

*On site VOCs treatment adsorption process project.

CN

CN