At present, almost all domestic and foreign production of hydrogen peroxide uses the anthraquinone method, which produces a small amount of anthraquinone organic compounds during the hydrogen peroxide production process. As the operating time of the device increases, the content of anthraquinone organic compounds will also increase. The organic carbon in hydrogen peroxide will seriously affect the quality of the product. For example, in the production of caprolactam, the ketoxime process route is mainly used. In traditional oximation and Beckman rearrangement reactions, cyclohexanone, ammonia, and hydrogen peroxide are placed in the same reactor to synthesize cyclohexanone oxime in one step. Therefore, hydrogen peroxide is the main raw material for synthesizing caprolactam, and the concentration of organic carbon in hydrogen peroxide needs to be reduced to below 50ppm in the reaction. If hydrogen peroxide with excessive organic carbon content is used for the production of cyclohexanone oxime, this organic matter will be carried into the final product caprolactam, which will affect the purity of the product.

Therefore, hydrogen peroxide needs to be purified. In order to remove these organic impurities from hydrogen peroxide products, many purification methods have been developed since the 1950s, which can be summarized as follows: distillation, adsorption, ion exchange, extraction, crystallization, membrane separation, and combinations of several methods. The commonly used methods in industry now are distillation and ion exchange resin purification.

Distillation is generally used to concentrate hydrogen peroxide because organic compounds have a high boiling point, so they are enriched and removed from the non vaporized liquid, thereby purifying the hydrogen peroxide. However, due to incomplete gas-liquid separation and the carrying of misty liquids, volatile organic compounds will enter the distillation system with hydrogen peroxide vapor, so the purity is generally not very high.

The ion exchange resin purification method is to pump the raw material hydrogen peroxide into an adsorption column and adsorb it with organic carbon. Then, the feed solution enters the cation exchange resin for ion exchange, and the feed solution is filtered to remove particle impurities to obtain ultra pure hydrogen peroxide product. Not only can it remove organic carbon, but it can also remove some metal ion impurities such as Fe, Al, Sn ions.

The basic principle of Jiangsu Haipu Functional Materials Co., Ltd.'s hydrogen peroxide purification treatment process is to use the adsorption performance of special adsorption materials to selectively adsorb and enrich organic carbon in hydrogen peroxide into the adsorption materials, reducing the organic carbon content in the adsorbed water. After adsorption saturation, the adsorbent material is subjected to desorption treatment to regenerate and resume adsorption, and this process is continuously repeated.

Jiangsu Haipu Functional Materials Co., Ltd. is committed to the research and industrialization of high-performance adsorbents and catalysts. In 2018, it was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterials Engineering Technology Research Center. Through years of independent research and development, it has achieved international leading levels in ion exchange technology and adsorption technology, nano inorganic material hybridization technology, etc., realizing the serialization of adsorption and catalytic products and successfully applying them in the fields of environmental protection and resource recycling. With a series of independently developed high-performance adsorbents and catalysts as the core, combined with self-developed process technology, Haipu has become a professional supplier of green and environmental protection solutions.

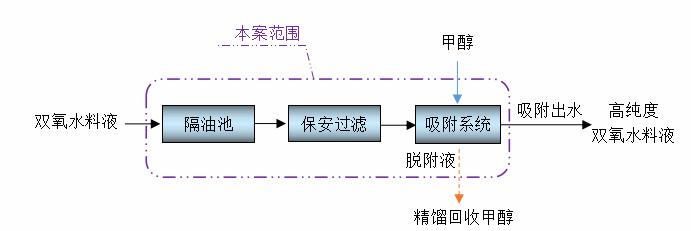

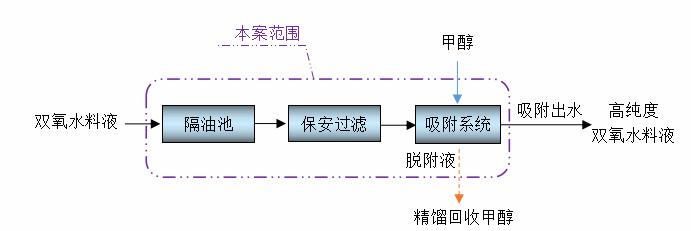

The hydrogen peroxide solution is first passed through a low-density oil separator to remove most of the organic solvents (aromatic hydrocarbons), and then filtered through a security filter to ensure that there are no suspended solids or small particles in the solution, preventing impurities from entering the adsorbent material and affecting its adsorption performance. The filtered material liquid is then sent to an adsorption tower containing special adsorption materials for adsorption treatment. After adsorption saturation, the adsorption materials are subjected to desorption and regeneration treatment. After regeneration, the adsorption materials can be reused, and the adsorbed water is high-purity hydrogen peroxide material liquid. The desorption liquid produced by desorption can be reused after distillation to recover methanol.

Figure 1 Process Flow Diagram

Firstly, the TOC in the adsorbent material is desorbed using a desorption agent, and then the residual desorption agent in the adsorbent material is washed away with methanol. The desorption agent methanol is applied, and the high concentration desorption liquid produced is distilled and recovered. The distillate can continue to be reused, adsorbing high-purity hydrogen peroxide.

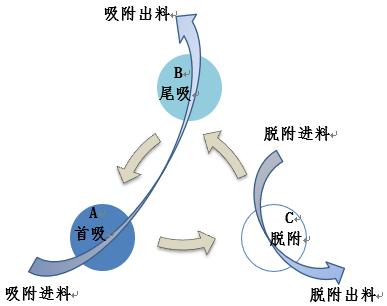

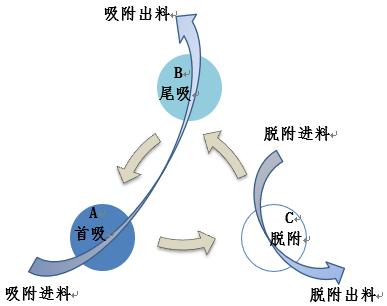

To ensure the continuous and stable operation of the device, and to ensure the effectiveness of the device's water output, the adsorption device adopts a 3 tower 2 series 1 desorption operation mode. Among them, 2 towers are connected in series at the beginning and end to adsorb the water output, and 1 tower is rotated for desorption. During desorption switching, the original first tower is desorbed, and the original tail tower is transformed into the first tower and then reconnected with the desorbed tower (used as the tail tower) to adsorb the water output. The illustrated process is shown in Figure 3, where each adsorption tower rotates its roles in the order of arrows during different operating periods.

Figure 3 Schematic diagram of the operation process of series adsorption (2 adsorption and 1 desorption)

This project adopts PLC program automatic control to monitor the temperature, pressure, liquid level and other parameters of the adsorption device in real time, achieving full automation operation. The PLC communicates with the upper computer, making it easy to grasp the operation of the device during production.

(1) Equipped with an independent operation control cabinet for easy management and daily maintenance;

(2) Control of the pump: The pump is linked to the corresponding tank level gauge and operates according to the height of the tank level; And each motor is equipped with an on-site operation column, which can switch between manual/automatic operation modes as needed.

(3) Automatic control of adsorption system: The water pump and automatic control valve switch automatically according to temperature, pressure, and operating time processes;

(4) Manual control of adsorption system: In order to cope with occasional situations that require individual device actions, the central console also has a manual system, which means that the control of each device is independent and may not be associated with other devices.

(5) The logic control diagram includes adsorption and desorption modules. The adsorption module has functions such as manual, automatic, stop, and start, while the desorption module has functions such as end, pause, resume, stop, and desorption start.

(6) All pumps and valves have two operation modes, manual control and automatic control, in the upper computer, which can achieve control of a single pump or valve.

Advantages of adsorption method

(1) Effectively reducing the concentration of TOC in the effluent can ensure that the effluent meets the discharge standards or the operational requirements of subsequent processes;

(2) Using specially modified adsorption materials, with large adsorption capacity, low equipment investment, and low operating costs;

(3) The process flow is simple and can achieve full automation operation, making operation and maintenance convenient;

(4) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs.

(5) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install.

(6) Advanced and mature technology, pollution-free, with strong technical support and rich engineering application experience.

CN

CN