Current situation of phosphorus removal

Excessive levels of phosphorus, nitrogen, and other elements in water can accelerate eutrophication, posing a threat to industry, aquaculture, agriculture, and tourism. Elevated concentrations of nutrients such as nitrogen and phosphorus are the cause of massive algal growth, with phosphorus being a key factor.

Phosphorus containing compounds in wastewater can be divided into two categories: organic phosphorus and inorganic phosphorus. The form of phosphorus in wastewater depends on the type of wastewater, with the most common being phosphate, polyphosphate, and organic phosphorus.

Wastewater discharged from industries such as chemical, papermaking, rubber, dyeing and textile printing, pesticides, coking, petrochemicals, fermentation, pharmaceuticals and medical, and food often contains organic phosphorus compounds.

Therefore, how to effectively reduce the concentration of phosphorus in sewage is of great significance for eliminating pollution and protecting the environment.

Product Introduction

To meet the needs of enterprises for efficient, low investment, low operating costs, mature technology, and high degree of automation in the treatment of phosphorus containing wastewater, the research team of Haipu Functional Materials has developed an adsorption resin product based on the characteristics of typical industry wastewater quality and treatment processes - Haipu Phosphorus Removal Resin.

Haipu phosphorus removal resin products have excellent physical and chemical stability, and the inner and outer surfaces contain functional groups with strong affinity for inorganic phosphorus, making them suitable for phosphorus removal and recovery.

At the same time as good phosphorus removal effect, this material is easy to regenerate and has strong resistance to organic pollution, with a long service life.

Haipu's multiple phosphorus removal resin products can meet the needs of organic and inorganic phosphorus wastewater treatment, including phosphorus removal from domestic sewage, chemical industry wastewater, and agricultural wastewater.

Product parameters

Haipu's multiple phosphorus removal resins can remove the majority of phosphorus from phosphorus containing wastewater, and the treated water is then sent to the biochemical system for treatment, reducing the operating pressure of the biochemical system and controlling the phosphorus content of the effluent to meet discharge requirements.

| Name | Index |

| Appearance | Brown spherical particles |

| Water content | 45.0-55.0% |

| Particle size range | (0.4-1.25mm) ≥95.0% |

| Wet visual density | 0.7-0.8 g/L |

| Sphericity ratio | ≥95.0% |

| Functional groups | Phosphorus removal active group |

| Skeleton medical degree | 0.90-1.00 g/L |

| Name | Numerical value |

| Adsorbent layer height | 2600 mm |

| Operating flow rate | 1-10 BV/H* |

| Using pH | 4.0-10.0 |

| Backwash expansion rate | 50.0-80.0% |

| Operating temperature | ≤90℃ |

*Physical and chemical properties and parameter indicators of phosphorus removal resin

When in use, the production wastewater is pre treated and enters the adsorption tower containing phosphorus removal resin products for adsorption and enrichment, and the phosphorus substances in the water are adsorbed and removed.

After adsorption saturation, desorption treatment is carried out using a desorption agent, and the desorbed adsorbent can be regenerated and reused for adsorption.

Moreover, the entire process system adopts a modular component form, with a high degree of automation and simple operation. Compared with other phosphorus removal technologies, Haipu phosphorus removal adsorbent has significant application advantages in terms of operating cost and efficiency.

Product and its supporting process characteristics

At present, there are several phosphorus removal technologies widely used in the corresponding market fields, including:

| Processing method | Characteristic | Shortcoming |

| Biological law | Biological phosphorus removal is a relatively economical phosphorus removal technology, which can remove 90% of the phosphorus in sewage under appropriate conditions. It is now commonly used in urban sewage treatment plants with low phosphorus content | The stability of process operation is poor, and the efficiency of phosphorus removal fluctuates greatly with changes in inlet water quality (pH, organic matter concentration, phosphorus content) and boundary conditions (temperature, etc.), making it difficult to recover phosphorus. In many cases, the effluent is difficult to meet the discharge standards for phosphorus |

| Chemical method | The treatment effect is stable and reliable, the operation is simple and flexible, the sludge will not release phosphorus again during the treatment and disposal process, and the ability to withstand impact loads is also strong | The chemical phosphorus removal method generates a large amount of water containing chemical sludge, which is difficult to treat. In addition, the cost of medication is relatively high, resulting in a higher concentration of residual metal ions and an increase in effluent color |

| Crystallization method | Adopting a filter based drainage method, it has a small footprint, low management costs, and is easy to control | When there is a large amount of organic matter in the sewage, it is easy to cause the failure of phosphorus removal agents, and a large amount of suspended solids can also cause blockage of the water reaction tower |

| Electrodialysis | The inlet water of the electrodialysis chamber passes through multiple pairs of anion and cation permeable membranes, and a direct current voltage is applied between the anion and cation membranes. Under the influence of the applied voltage, phosphorus containing and nitrogen-containing ions, as well as other dissolved ions, will pass through the membrane and enter the solution on the other side, thereby achieving separation | It is just a method of concentrating phosphorus, and it cannot fundamentally remove phosphorus on its own |

Compared with the above phosphorus removal technologies, the advantages of Haipu phosphorus removal resin products and their supporting processes are as follows:

Long service life of products: Haipu phosphorus removal resin products have high mechanical strength, good stability, stable regeneration performance, and long service life.

System intelligent control: PLC fully automatic operation, high degree of automation, simple operation.

Purchasing high-quality big brands: selecting top domestic and foreign brands for electrical appliances and instruments.

Low overall operating costs: Low operating costs, stable and reliable treatment effects, and can withstand water quality fluctuations and impacts.

Low difficulty in process installation: The process equipment is reliable and stable, and the modular design is also easy to maintain and manage.

Product application effect

Haipu phosphorus removal resin products and their supporting combination processes have helped multiple customers meet their treatment needs for inorganic phosphorus and organic phosphorus wastewater.

01

Application Case 1

A resource utilization process design was carried out for a certain biotechnology enterprise's 500t/d organic phosphorus containing wastewater to solve the problem of substandard biochemical treatment of the enterprise's wastewater and the inability to recover effective components such as organic phosphorus. One day, approximately 10.2t of organic phosphorus can be recovered, and 10.68t of organic phosphorus can be recovered. Recovering both products can increase considerable economic benefits for the enterprise in one year.

| Name | Water volume (m³/d) | Organic phosphorus 1 (mg/L) | Organic phosphorus 2 (mg/L) |

| Device water inlet | ~500 | ~24000 | ~11600 |

| Device effluent | ~500 | <1400 | <1 |

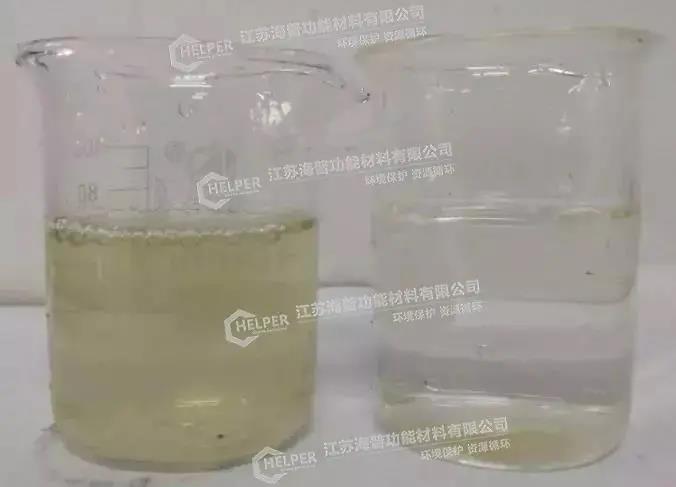

*Appearance of raw water (left) and adsorbed effluent (right)

02

Application Case 2

A biochemical enterprise can generate 65 tons of phosphorus containing wastewater per day, with a particularly high phosphorus content. Conventional biochemical treatment methods cannot achieve standard discharge, which puts great pressure on the continuous production of the enterprise. By using the phosphorus removal resin adsorption material developed by Haipu to adsorb and treat the wastewater, the problem of the enterprise's wastewater not meeting the standard can be solved.

| Phosphorus content in raw water | Phosphorus content in effluent | Removal rate |

| 1500mg/L | 245.1mg/L | 83.70% |

| 1500mg/L | 251.4mg/L | 83.30% |

| 1500mg/L | 243.8mg/L | 83.70% |

*Appearance of raw water (left) and adsorbed effluent (right)

03

Application Case 3

Process design for 200t/d phosphorus containing wastewater from an electroplating and spraying enterprise, deeply removing phosphorus elements from the wastewater. The total phosphorus content in the adsorbed water can be stabilized below 1mg/L, meeting the requirements of the enterprise. The adsorbed water can be directly discharged.

| Phosphorus content in raw water | Phosphorus content in effluent | Removal rate |

| 17mg/L | 0.95mg/L | 94.41% |

| 17mg/L | 0.98mg/L | 94.24% |

| 17mg/L | 0.92mg/L | 94.58% |

04

Application Case 4

A company requires that the organic phosphorus content in the treated wastewater be less than 10mg/L. Experimental treatment results show that using adsorption treatment can stabilize the removal rate of organic phosphorus in the wastewater at over 99%, and the phosphorus content in the effluent can be controlled below 6mg/L.

While ensuring compliance with customer requirements, leaving a certain safety margin can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent. The treatment effect is shown in the following figure.

| Phosphorus content in raw water | Phosphorus content in effluent | Removal rate |

| 624mg/L | 5.6mg/L | 99.10% |

| 624mg/L | 5.2mg/L | 99.17% |

| 624mg/L | 4.6mg/L | 99.26% |

*Appearance of raw water (left) and adsorbed effluent (right)

On site treatment of resin products and supporting processes

*On site organic phosphorus wastewater treatment project

CN

CN