Overview

High salt wastewater refers to wastewater with a total salt content of at least 1% by mass. It mainly comes from chemical plants and the collection and processing of oil and natural gas. This type of wastewater contains various substances (including salt, oil, organic heavy metals, and radioactive substances). The generation pathways of saline wastewater are extensive, and the amount of water is increasing year by year. It is crucial to remove the impact of organic pollutants in saline wastewater on the environment.

High salt wastewater comes from a wide range of sources. In chemical production, incomplete chemical reactions or by-products of chemical reactions, especially the large amount of toxic wastewater with high COD and high salt generated during the production of chemical products such as dyes and pesticides, are involved; In the process of wastewater treatment, the addition of water treatment agents and acids and bases can lead to mineralization, as well as the concentration of soluble salts in most of the concentrated solutions produced after water recovery, resulting in high salinity wastewater that is difficult to biologically treat. Therefore, the purification of salt from high salt wastewater generated in industrial production is a major industry challenge and an urgent need for many enterprises.

At present, most enterprises in China mainly treat high salt wastewater by removing organic matter and desalination. The commonly used methods include distillation, membrane separation, microfiltration, biological treatment technology, or the simplest incineration method. However, these methods are either difficult to operate, expensive to process, and cannot purify the final salt, so the final effect is not very ideal.

Current situation and dilemma of high salt wastewater

High salt wastewater mainly comes from chemical plants and the collection and processing of oil and natural gas. This type of wastewater contains various substances, including salt, oil, organic heavy metals, and radioactive substances. It is crucial to remove the impact of organic pollutants in saline wastewater on the environment. Its characteristics are low biodegradability, high COD concentration, high chromaticity, toxicity, etc. Conventional water treatment techniques are difficult to treat, and the purification of its salts has become a difficult point in industrial wastewater treatment.

① Generally, high salt wastewater has a large color and is difficult to remove using conventional methods;

② High salt wastewater is toxic, with a wide variety of substances and low biodegradability.

In recent years, the country has attached increasing importance to ecological environment protection, and the standards for wastewater discharge and the total control of regional wastewater discharge have become increasingly strict. In order to ensure the sustainable development of related industries, new ideas have been constantly presented for the treatment of high salt wastewater. The main methods for treating high salt wastewater include distillation, oxidation, special adsorbent adsorption, membrane separation, incineration, etc.

Distillation method - Multi effect evaporation technology (MED)

In evaporation production, the output of secondary vapor is relatively large and contains a large amount of latent heat, so it should be recovered and utilized. If the secondary vapor is introduced into the heating chamber of another evaporator, as long as the operating pressure and boiling point of the latter are lower than those in the original evaporator, the introduced secondary vapor can still serve as a heating agent for multiple evaporation operations. This method can effectively desalinate, but its disadvantage is that it cannot remove organic matter. The color of the salt is darker and can only be treated as hazardous waste.

Oxidation method

The oxidation method is an oxidation system composed of strong oxidants and catalysts added to wastewater, which generates organic free radicals with recalcitrant organic matter in aqueous solution to destroy its structure and ultimately oxidize and decompose it. It can effectively remove recalcitrant organic matter that cannot be removed by traditional wastewater treatment techniques. This can also achieve the purpose of decolorizing and purifying high salt wastewater to a certain extent. But this method also has some drawbacks:

(1) The consumption of oxidants is high when dealing with high concentration pollutants, resulting in high costs for wastewater treatment;

(2) There is a certain range of applicable pH values, which must be carried out under limited pH conditions;

(3) The conventional oxidation system is prone to introducing metal ions, requiring subsequent treatment to recover the catalyst, and the recovery cost is high, the process is complex, and it is prone to secondary pollution.

Special adsorbent adsorption method

Adsorption method refers to the use of the special adsorption function of adsorption materials to adsorb and enrich specific pollutants in wastewater, thereby reducing the concentration of pollutants in wastewater and achieving the goal of purifying wastewater. After adsorption saturation, the adsorbent material is desorbed using a desorption agent to regenerate the adsorbent material, which can be reused. Adsorption method is a very simple and direct wastewater treatment technology that can remove difficult to treat or degrade organic compounds in high salt wastewater, resulting in colorless adsorbed water and ultimately achieving the goal of purifying salt. Adsorption method has strong adsorption capacity, easy regeneration, low operating cost, mature process technology, and has become an effective method for treating high salt wastewater.

Membrane separation method

Membrane separation technology is a novel separation technique that utilizes the differential permeability of membranes to separate, purify, and concentrate target substances in a mixture. The commonly used membrane technologies currently include ultrafiltration, microfiltration, electrodialysis, and reverse osmosis. When ultrafiltration and microfiltration are used for the treatment of high salt wastewater, they can only effectively intercept suspended solids and colloids in the wastewater, and cannot achieve the final purification effect. Although electrodialysis and reverse osmosis technologies can achieve desalination, it is difficult or impossible to remove organic matter from the water. The disadvantage of membrane technology is that if the organic content in wastewater is high, the membrane is easily contaminated, which makes it difficult for the operation process to operate normally, and the treatment cost is high, which is difficult for general enterprises to afford.

Incineration method

The incineration method is the simplest and does not require purification of salt. It can be directly incinerated or concentrated before incineration. The flue gas must be treated, which is a method used by many enterprises to treat high salt wastewater. At present, hazardous waste treatment centers in various regions charge high incineration costs for this type of wastewater, and due to the high salt content, the incineration difficulty is slightly higher, generally around thousands of yuan per ton of water. With the improvement of environmental protection requirements, the cost of incinerating high salt wastewater may also increase, which is difficult for enterprises to afford.

Although the oxidation method is effective in purifying salt from high salt wastewater, it cannot completely oxidize and decompose organic matter, and is prone to secondary pollution; The incineration method is not a long-term and economical method for purifying salt in wastewater due to its high commission cost. The adsorption method can efficiently remove organic matter from wastewater and is an economical and effective method for purifying salt in high salt wastewater.

Industry customer demand

The composition of high salt wastewater in the chemical industry is complex, containing a large amount of organic substances with benzene rings or other heterocycles, some of which have extremely high chromaticity and high COD. Therefore, the wastewater must be treated and cannot be directly discharged. Various methods for purifying salt from high salt wastewater cannot achieve both color removal and COD removal. Therefore, achieving the optimal treatment effect and economic cost is currently a development direction in high salt wastewater treatment.

The needs of high salt wastewater treatment for enterprise customers include the following three points:

(1) Efficient and stable removal of colored substances from wastewater, and effective removal of high COD to purify salts;

(2) Low investment cost, low operating cost, and convenient equipment operation and maintenance;

(3) Advanced and reliable technology, with no secondary pollution.

Introduction to Haipu Customized Process

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

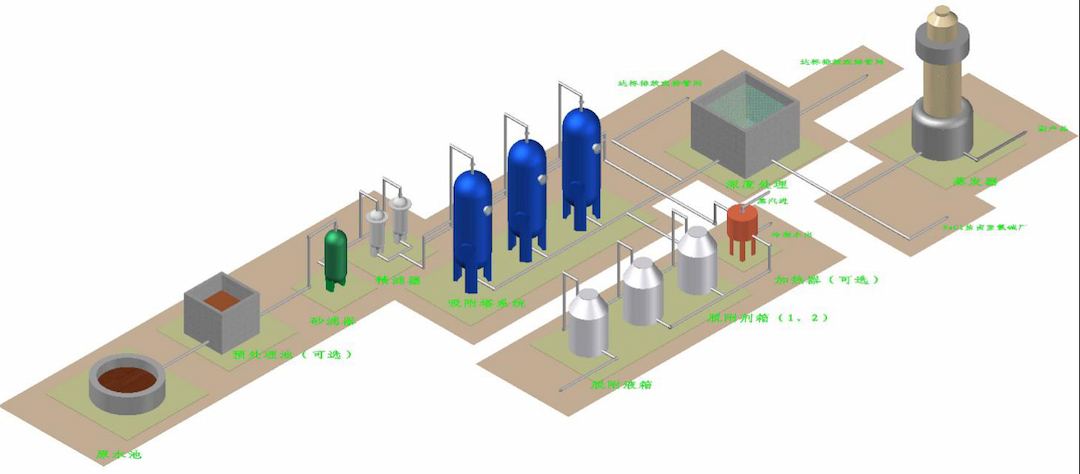

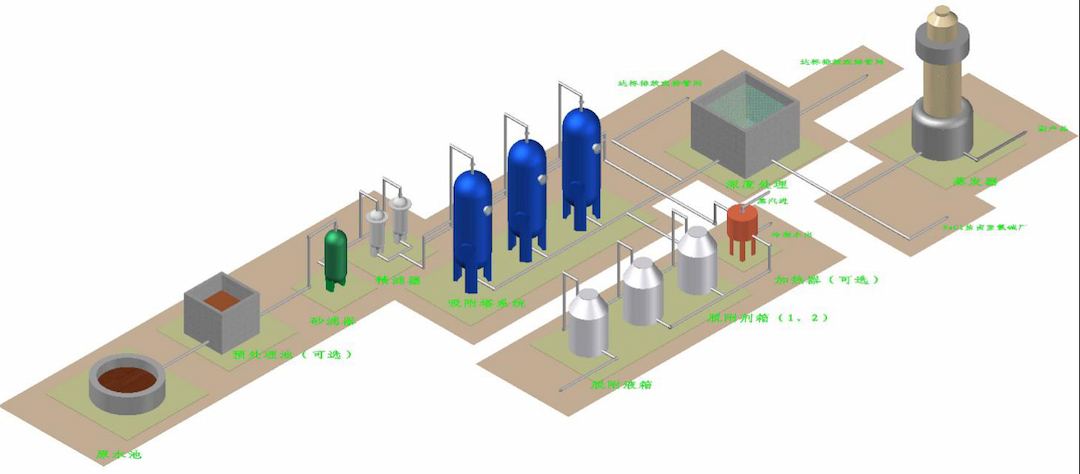

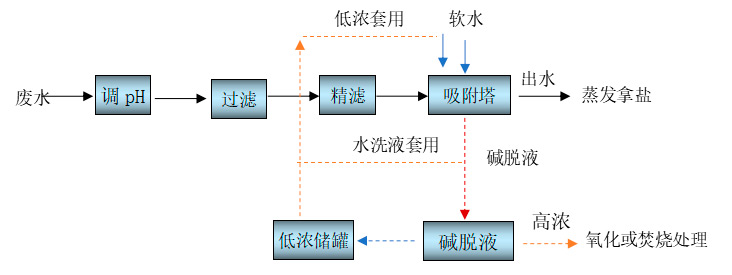

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to regenerate. This process is continuously repeated. The conventional process diagram for treating wastewater by adsorption method is shown in Figure 1.

Figure 1 Conventional process diagram for adsorption treatment of wastewater

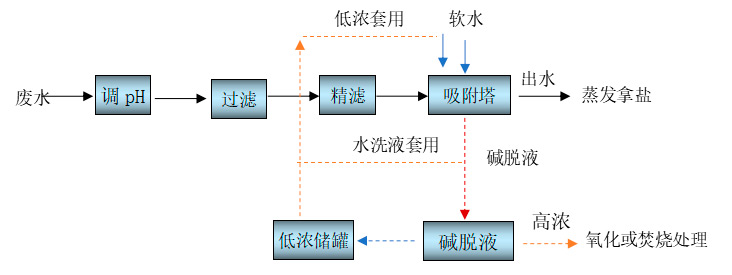

When using Haipu's adsorption process to treat high salt wastewater, the wastewater is pre adjusted for pH, and then filtered to remove suspended and particulate matter. After that, it enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb colored substances and related organic substances in the wastewater on the surface of the material, achieving the removal of colored substances and organic substances. After adsorption saturation, the colored and organic substances on the adsorbent material are first desorbed with alkaline solution, which is then transferred into the desorption solution. The residual alkaline solution on the surface of the adsorbent material is washed away with a small amount of soft water, and then activated with a small amount of acid. The desorption solution can be oxidized or directly sent for incineration treatment. Adsorbed water is a type of wastewater used to remove colored substances and related organic matter, which is almost pure saltwater. It can be subjected to subsequent MVR salt evaporation operations to obtain pure salt, which can be used as a byproduct or solid waste. The process flow is shown in Figure 2.

Figure 2 Adsorption treatment process flow of anthraquinone waste acid water

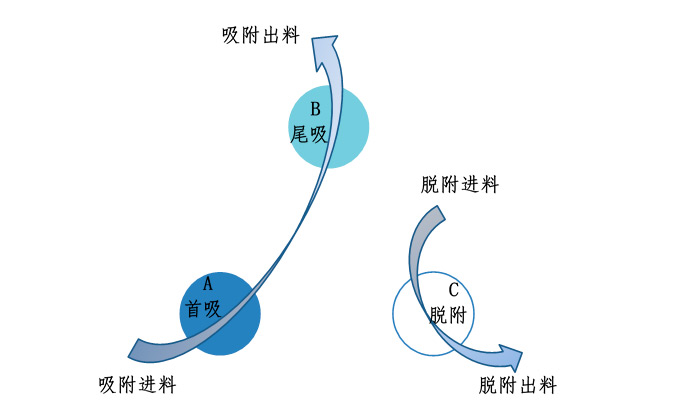

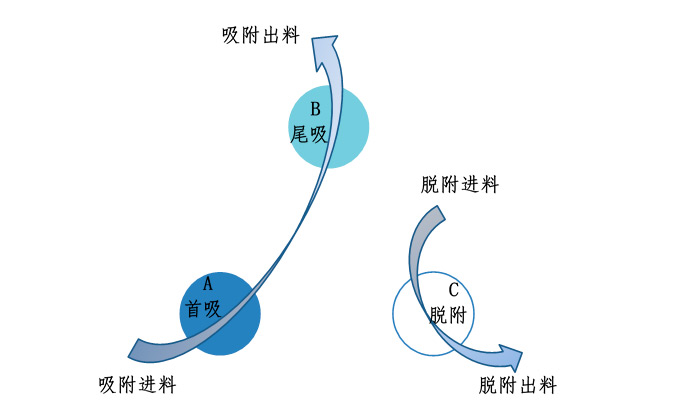

Considering the fluctuation of high salt wastewater and the continuity of device operation, to ensure stable treatment effect, the industrial adsorption scheme requires the installation of three adsorption towers in two series and one desorption, that is, two in series for adsorption and one in rotation for desorption. Each time the front tower undergoes desorption, the desorbed tower is connected in series with the adsorption stage. Before desorption, the three towers are switched through pipeline valves to achieve different operating states, allowing each tower to circulate sequentially between the desorption, front tower, and rear tower processes. The illustrated process is shown in Figure 4-3, where each adsorption tower rotates its roles in the order of arrows during different operating periods.

Figure 3 Schematic diagram of the operation process of series adsorption (2 adsorption and 1 desorption)

Process treatment effect

The use of adsorption technology to treat high salt wastewater can effectively remove colored and organic substances from the wastewater. The specific treatment data is shown in Table 1.

Table 1 Adsorption and decolorization data of wastewater

| Raw water color | Raw water COD (mg/L) | Water color | Effluent COD (mg/L) |

| Oxblood red | ~60000 | Transparent and colorless | 450 |

| Oxblood red | ~60000 | Transparent and colorless | 410 |

| Oxblood red | ~60000 | Transparent and colorless | 480 |

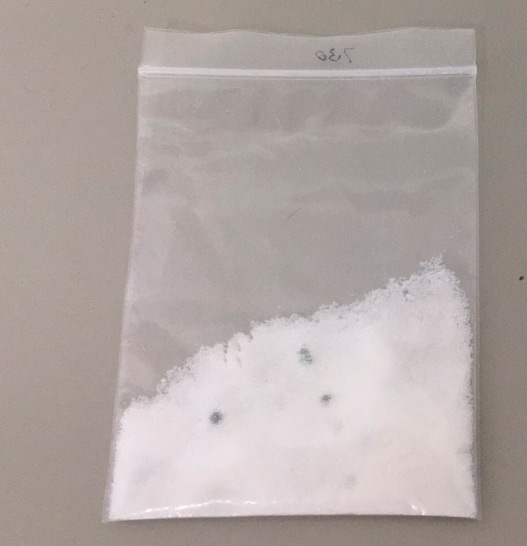

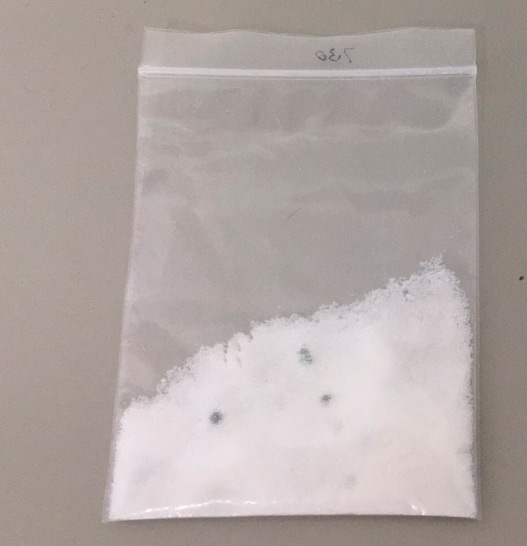

The enterprise requires that the treated wastewater be colorless and the evaporated salt be white. The experimental treatment effect shows that adsorption treatment has a very high removal rate of colored substances and organic matter in the wastewater, and the effluent is transparent and colorless. The laboratory evaporated salt is white, which meets the customer's requirements very well. The treatment effect is shown in the following figure.

Figure 4 Appearance of Raw Water (left), Pre treated Water (middle), and Adsorbed Water (right)

Figure 5 Laboratory effluent steam salt

Figure 6 Comparison of salt output before and after treatment using our company's process system in enterprises (left for pre treated salt evaporation, right for post treated salt evaporation)

The company requires that the distilled salt water be white and treated as solid waste. Adsorption treatment is used for wastewater, and experimental results show that the removal rate of colored and organic substances in the wastewater is over 99%. The effluent is transparent and colorless, and the evaporated salt in the effluent is white. It can be completely treated as solid waste, and some can even be treated as by-products to reduce production costs.

Core advantages of the process

At present, the treatment methods for purifying salt from high salt wastewater have their own shortcomings in terms of treatment efficiency and operating costs.

The oxidation method has a certain removal efficiency for high salt wastewater, but the materials used in the oxidation method are prone to failure and agglomeration, and the oxidation method generates a large amount of sludge, making subsequent treatment complex and increasing the cost of wastewater treatment.

Membrane separation technology is difficult or impossible to remove organic matter from water. Another disadvantage is that if the organic content in the wastewater is high, the membrane is easily contaminated, which makes it difficult for the operation process to operate normally, and the treatment cost is high, which is difficult for general enterprises to afford.

The incineration method for wastewater treatment has a particularly high cost, which puts great pressure on the production of enterprises. Therefore, it is urgent to find a cost-effective, environmentally friendly, and efficient treatment method, which is also the focus of the current high salt wastewater purification and salt treatment industry.

The use of special adsorbent adsorption method to treat anthraquinone wastewater can efficiently remove colored substances from the wastewater, ensuring that the treated wastewater is transparent and colorless, meeting the requirements of enterprises. The advantages of adsorption method are as follows:

(1) Efficiently remove colored substances from wastewater and purify their salts to meet solid waste standards;

(2) Greatly reducing the cost of wastewater treatment for enterprises, the treatment cost of adsorption method is generally 25-35 yuan/ton, much lower than the cost of incineration treatment;

(3) Conduct experiments on sampling samples of wastewater generated on-site by enterprises, based on theory and technology, and design adsorption processes based on experiments. The matching degree between wastewater and processes is 100%;

(4) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs;

(5) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install;

(6) Advanced and mature technology, no secondary pollution, strong technical support, and rich engineering application experience.

Economic benefit analysis

Economic Benefit Analysis of Purification of Salt by Wastewater Adsorption Method

According to the salt purification treatment project plan for high salt wastewater designed by our company, the adsorption method is used to remove colored and organic substances from the wastewater. When the treatment scale is 200 tons/day, the investment in the adsorption device is about 4.8 million yuan, including about 2.8 million yuan for the adsorption equipment. The operating cost of the salt purification and adsorption process for high salt wastewater is about 35 yuan/ton. Based on a daily treatment of 200 tons and a one-year operating time of 330 days, the annual operating cost is 2.31 million yuan; The operating cost of desorption liquid incineration is 6000 yuan/day, and the annual operating cost is 1.98 million yuan; After adsorption treatment, the wastewater is subjected to salt evaporation to convert hazardous waste into solid waste. The annual cost of hazardous waste treatment is about 26.4 million yuan, and the conversion into solid waste is about 3.3 million yuan, saving nearly 23.1 million yuan. The investment in the entire equipment is about 4.8 million yuan, and its annual operating cost is about 4.29 million yuan, saving the enterprise a lot of funds.

Service Process

Laboratory Small-Scale Test The R&D team conducts tests based on customer water samples and provides a detailed water quality test report.

On-Site Pilot Test Based on customer needs and scientific data, we provide cost-effective solutions, engineering commissioning, and personnel training.

Design and Construction Mainly in the form of fixed beds, saving floor space, and optimizing space layout based on on-site conditions.

Engineering Commissioning and Personnel Training Low investment, simple operation, high automation, low operation and maintenance costs, and professional training for operation.

After-Sales Service Ensuring customers pass relevant environmental acceptance smoothly, with a professional after-sales team providing 24/7 technical services.

CN

CN