Aniline is one of its important amine substances, and aniline compounds are representative of aromatic amines. They are used in the manufacture of dyes, drugs, resins, rubber vulcanization accelerators, and black dyes. Due to its oxidation and coloration, it has a special odor, high toxicity, and carcinogenic effects on the human body. Therefore, the treatment of wastewater from the aniline and nitrobenzene industries has become increasingly strict and requires compliance with treatment standards. So, how to treat aniline and nitrobenzene wastewater? Below, Haipu will provide a detailed introduction, hoping to be helpful to you.

Nitrobenzene is an easily producible explosive and an important organic intermediate. Nitrobenzene can be used as an intermediate in dyes, pharmaceuticals, and other industries. Nitrobenzene is chlorinated to obtain m-nitrochlorobenzene, which is widely used in the production of pesticides and other products.

The nitrobenzene in the environment mainly comes from the wastewater and exhaust gas of chemical and dye factories, especially the wastewater discharged from aniline dye factories, which contains a large amount of nitrobenzene. Accidents during storage and transportation can also cause serious pollution of nitrobenzene. Wastewater containing nitrobenzene compounds has complex components, high toxicity, high chromaticity, high COD, and is difficult to biodegrade, posing a significant threat to the ecological environment. Therefore, the treatment of wastewater in the industry has become increasingly strict and must meet the standards.

At present, most enterprises in China usually use a single oxidation method to treat wastewater containing aniline and nitrobenzene, which is difficult to achieve ideal results. We need a wide range of treatment methods for wastewater containing aniline and nitrobenzene, which can degrade or convert highly toxic and difficult to biodegrade pollutants into easily degradable substances as much as possible, and achieve better results through simple treatment.

Current situation and dilemma of aniline and nitrobenzene wastewater:

Aniline and nitrobenzene are important chemical raw materials widely used in industries such as chemical, pharmaceutical, printing and dyeing, and pesticide production. They are also carcinogenic, teratogenic, and mutagenic environmental pollutants. The wastewater quality is complex, containing a large amount of non biodegradable substances, with high COD concentration and high toxicity. Conventional water treatment techniques are difficult to treat and have become a challenge in industrial wastewater treatment.

In recent years, the country has attached increasing importance to ecological environment protection, and the standards for wastewater discharge and the total control of regional wastewater discharge have become increasingly strict. In order to ensure the sustainable development of industries related to the application of aniline and nitrobenzene, new ideas for the treatment of wastewater containing benzene and nitrobenzene have also emerged. In recent years, the main methods for treating such wastewater include photocatalytic oxidation, Fenton oxidation, adsorption, microelectrolysis, incineration, etc.

However, the industrial application technology of photocatalytic oxidation in the treatment of these three types of aniline and nitrobenzene wastewater is not yet mature. The Fenton oxidation method has incomplete organic matter oxidation and decomposition, and the effect is not optimal. The incineration method is not a long-term and economical wastewater treatment method due to high commission costs. The adsorption method can efficiently remove aniline and nitrobenzene from the wastewater, making it an economical and effective method for treating such wastewater.

Industry customer demand:

The composition of aniline and nitrobenzene wastewater is complex, containing a large amount of toxic and harmful substances, and cannot be directly subjected to biochemical treatment. Effective treatment of wastewater is necessary. After pretreatment of various aniline and nitrobenzene wastewater, it is necessary to combine traditional biochemical treatment technologies or other related technologies to achieve the optimal treatment effect and economic cost. This is a development direction in the treatment of aniline and nitrobenzene wastewater.

The treatment of wastewater from enterprises producing aniline and nitrobenzene includes the following three points:

(1) Efficiently and stably removing toxic substances such as aniline and nitrobenzene from wastewater, the treated effluent can enter the biochemical tank for biochemical treatment or other related subsequent treatment procedures;

(2) Low investment cost, low operating cost, and convenient equipment operation and maintenance;

(3) Advanced and reliable technology, with no secondary pollution.

Introduction to Haipu customized process:

Jiangsu Haipu Functional Materials Co., Ltd. is located in Suzhou Industrial Park. It is a national high-tech enterprise that uses special adsorbents and catalysts as its core technology, supporting the development of application processes, technical services, engineering implementation, etc., to solve related environmental problems for customers. Haipu's technical team won the Suzhou Industrial Park Leading Talent Award in 2013 and 2015, and the Gusu Leading Talent Award in 2015. Jiangsu Haipu Functional Materials Co., Ltd. was rated as a national high-tech enterprise twice in 2015 and 2018, and was approved as the Suzhou Adsorption and Catalytic Functional Nanomaterial Engineering Technology Research Center in 2018. Jiangsu Haipu Functional Materials Co., Ltd. has a leading technological level in the treatment of adsorption materials. The supporting adsorption treatment process is efficient and stable, and has solved multiple environmental problems for many leading domestic enterprises in the industry.

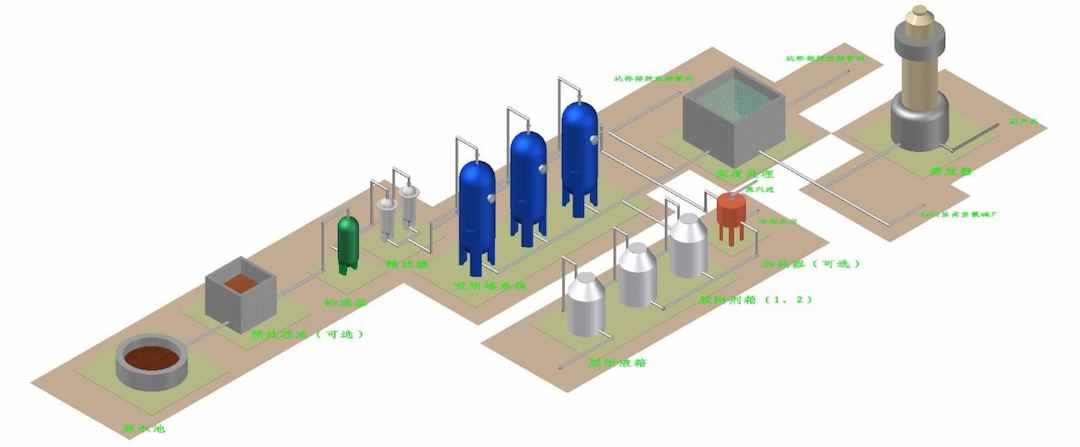

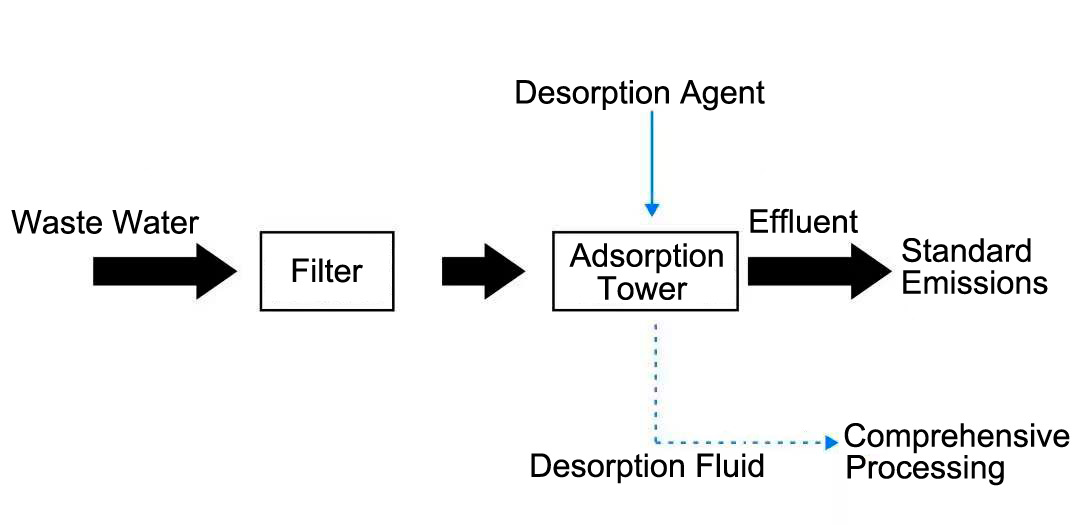

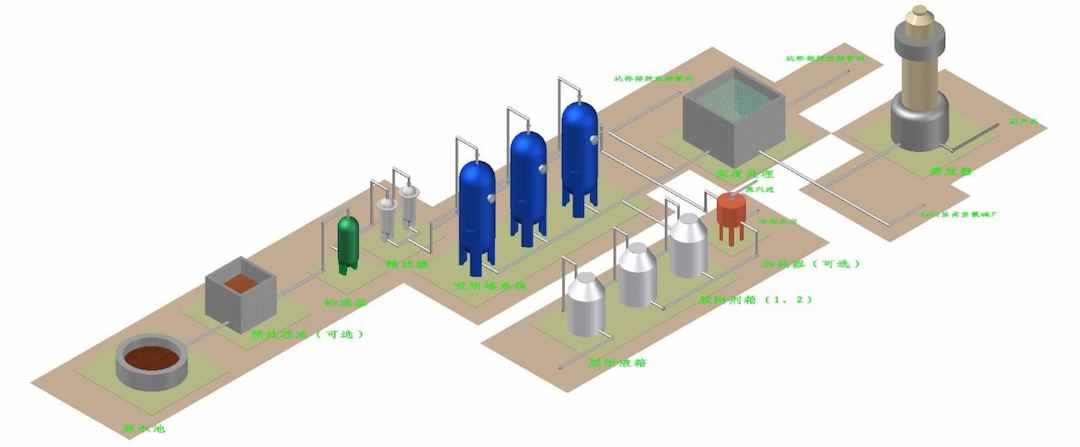

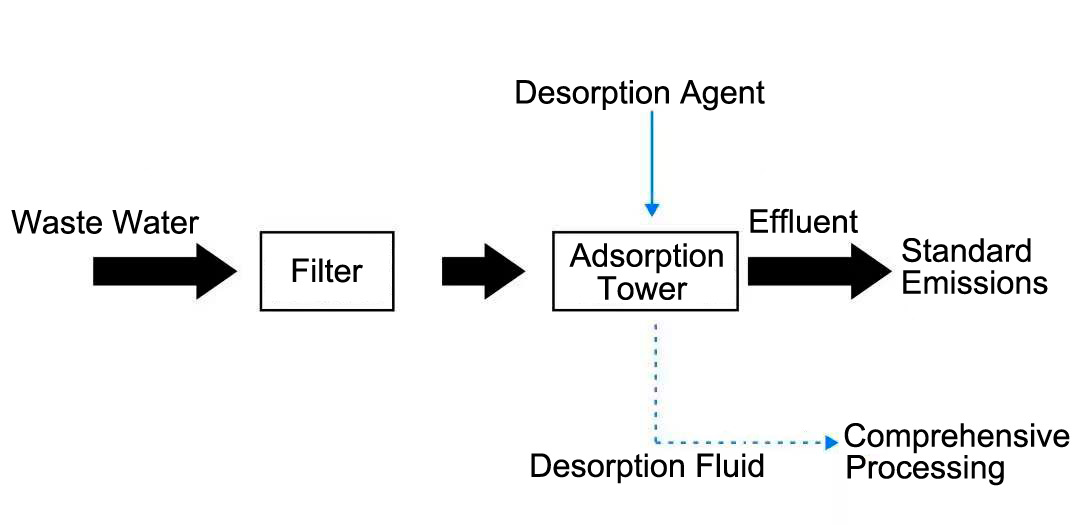

The principle of the Haipu adsorption process is to use the special adsorption materials developed by our company to selectively adsorb the components or substances to be removed. When the adsorption is saturated, a specific desorption agent is used to desorb the adsorption material, allowing it to regenerate. This process is continuously repeated. The conventional process diagram for treating wastewater by adsorption method is shown in the following figure.

Conventional process diagram for adsorption treatment of wastewater

Using Haipu's adsorption process to treat aniline and nitrobenzene wastewater, the wastewater is pre filtered to remove suspended and particulate matter, and then enters the adsorption tower for adsorption. The special adsorption material filled in the adsorption tower can adsorb aniline and nitrobenzene in the wastewater on the surface of the material, achieving the removal of toxic and difficult to biodegrade substances. After adsorption saturation, specific desorption agents are used to desorb the adsorbent material, allowing it to regenerate, and this process is continuously repeated. The adsorbed water is used to remove aniline and nitrobenzene wastewater, which can be directly treated in the biochemical system or other related treatments. The adsorption treatment process flow is shown in the figure.

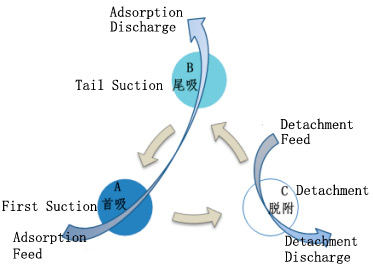

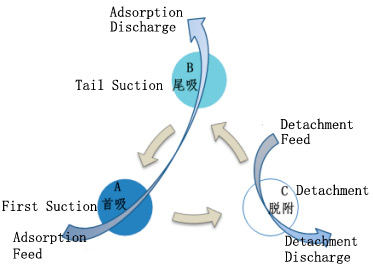

Due to the fluctuation of wastewater and the continuity of device operation, to ensure stable treatment effect, the industrial adsorption scheme requires the installation of three adsorption towers, two in series and one for desorption, that is, two in series for adsorption and one in rotation for desorption. Each time the front tower undergoes desorption, the desorbed tower is connected in series with the adsorption stage. Before desorption, the three towers are switched through pipeline valves to achieve different operating states, allowing each tower to circulate sequentially between the desorption, front tower, and rear tower processes. Each adsorption tower rotates its roles in the order of arrows during different operating periods.

Process treatment effect:

The adsorption process is used to treat wastewater containing aniline and nitrobenzene, which can effectively remove aniline and nitrobenzene from the wastewater. The specific treatment data is shown in the following figure:

Data on Adsorption and Removal of Aniline from Wastewater

| Aniline content in raw water | Aniline content in effluent | Removal Rate |

| 1600mgL | 12.3 mg/L | 99.20% |

| 1600mgL | 12.2 mg/L | 99.20% |

| 1600mgL | 11.9 mg/L | 99.30% |

Data on the adsorption and removal of nitrobenzene from wastewater

| Raw water nitrobenzene content | Nitrobenzene content in effluent | Removal Rate |

| 1992.5mg/L | 173.8mg/L | 91.30% |

| 1992.5mg/L | 147.9mg/L | 92.60% |

| 1992.5mg/L | 159.9mg/L | 92.00% |

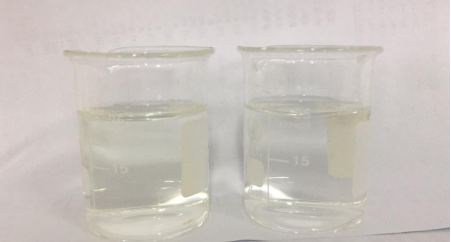

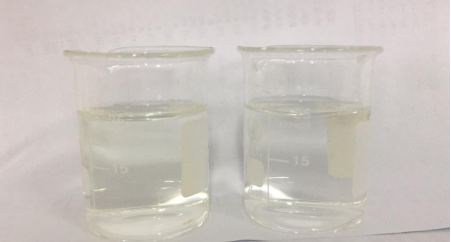

The enterprise requires that the aniline content in the treated wastewater be less than 20mg/L and the nitrobenzene content be less than 200mg/L. The experimental treatment effect shows that using adsorption treatment, the aniline removal rate in the wastewater remains stable at over 99%, and the nitrobenzene removal rate remains stable at over 91%. While ensuring compliance with customer requirements, leaving a certain safety margin can effectively prevent water quality fluctuations in the incoming wastewater from causing substandard effluent. The treatment effect is shown in the following figure.

Aniline: Appearance of raw water (left) and adsorbed effluent (right)

Nitrobenzene: Raw water (left) slightly yellow, adsorbed effluent (right) colorless appearance image

The aniline and nitrobenzene wastewater generated during the production process of the enterprise contains aniline, nitrobenzene, ammonia nitrogen, etc., with a COD of nearly 10000 mg/L. To meet the needs of the subsequent treatment process, the vast majority of aniline and nitrobenzene are removed. The production wastewater of the enterprise requires that the treated aniline content be less than 20mg/L and nitrobenzene be less than 200mg/L. The experimental results show that adsorption can remove the vast majority of aniline and nitrobenzene in the wastewater, meeting the requirements of the enterprise. At the same time, it also has a high removal rate for COD and ammonia nitrogen in the wastewater, which reduces the pressure on the subsequent treatment of the enterprise's wastewater.

The experimental treatment effect shows that the removal rates of aniline and nitrobenzene in wastewater can reach over 99% and 91% respectively, and the content in the effluent can be effectively controlled within the requirements of the enterprise. The subsequent wastewater can be directly treated by biochemical treatment or other methods, greatly reducing the trouble and cost of subsequent treatment.

Core advantages of craftsmanship:

At present, the treatment methods for aniline and nitrobenzene wastewater have their own shortcomings in terms of treatment efficiency and operating costs.

Nowadays, many enterprises are facing difficulties in the treatment of aniline and nitrobenzene wastewater. The process is cumbersome and cannot achieve the desired effect, which brings great pressure to the production of enterprises. Therefore, it is urgent to find a cost-effective, environmentally friendly, and efficient treatment method, which is also the focus of the current aniline and nitrobenzene wastewater treatment industry.

The use of adsorption method to treat aniline and nitrobenzene wastewater can efficiently remove aniline and nitrobenzene from the wastewater, ensuring that the corresponding content of the treated wastewater is within the requirements of the enterprise. Toxic and difficult to degrade substances in the wastewater are almost removed, meeting the requirements of the enterprise and reducing the pressure of subsequent wastewater treatment. The advantages of adsorption method are as follows:

(1) Efficiently remove aniline and nitrobenzene from wastewater, while reducing COD content and achieving high removal efficiency. Strictly control the concentration of aniline and nitrobenzene in the treated wastewater.

(2) Greatly reducing the cost of wastewater treatment for enterprises, the treatment cost of adsorption method is generally 15-20 yuan/ton, far lower than the cost of other treatment methods.

(3) Conduct experiments on the sampling samples of wastewater generated on the enterprise site, based on theoretical technology, and design adsorption processes based on experiments. The matching degree between wastewater and processes is 100%.

(4) The equipment occupies less land, has a compact structure, and requires less investment in civil engineering and equipment; The desorption agent is applied multiple times and concentrated step by step, resulting in high drug utilization and low operating costs.

(5) It can be implemented in module component form, flexibly adjusted according to production capacity, and easy to install.

(6) Advanced and mature technology, no secondary pollution, strong technical support, and rich engineering application experience.

CN

CN